Positive photosensitive resin composition, positive photosensitive dry film, method for producing same, and method for forming pattern

A technology of photosensitive resin and photosensitive resin layer, which is applied in the field of electronic parts, can solve the problems of miniaturization and insufficient study of pattern shape, and achieve the effects of good adhesion, excellent reliability, and excellent drug resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

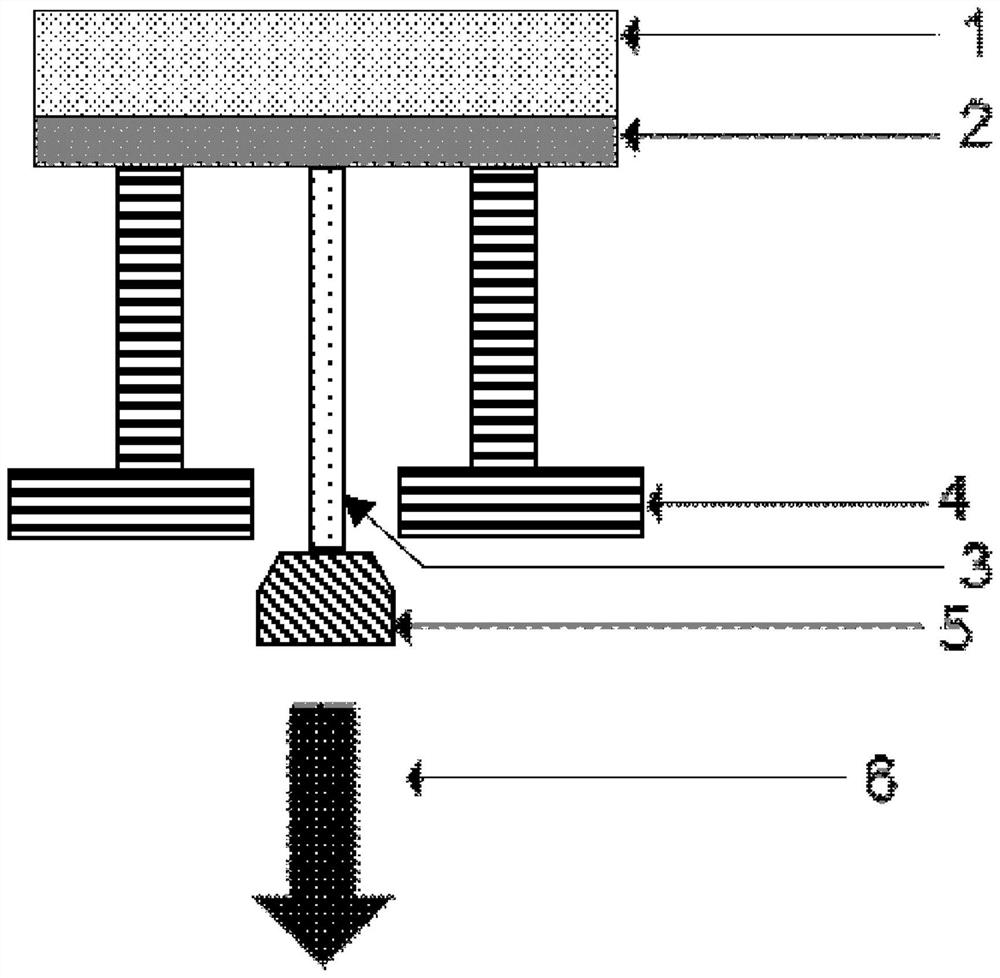

Image

Examples

Embodiment

[0429] Hereinafter, the present invention will be specifically described with reference to synthesis examples, examples, and comparative examples, but the present invention is not limited to the following examples. In addition, weight average molecular weight (Mw) shows the polystyrene conversion weight average molecular weight obtained by GPC.

[0430] I. Synthesis of Alkali-Soluble Resin (A)

[0431] The chemical structural formulas and names of the compounds used in the following synthesis examples are shown below.

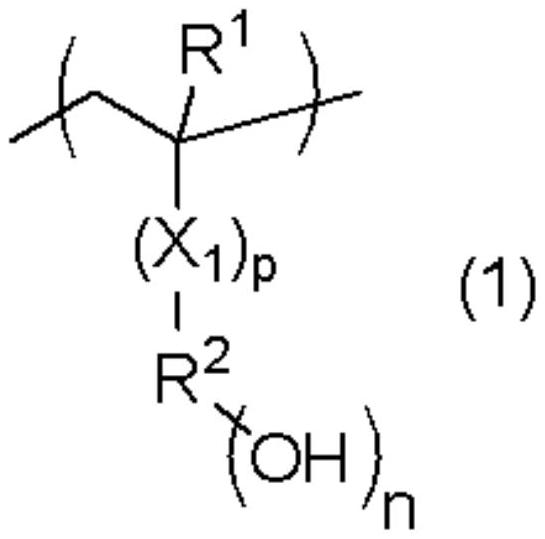

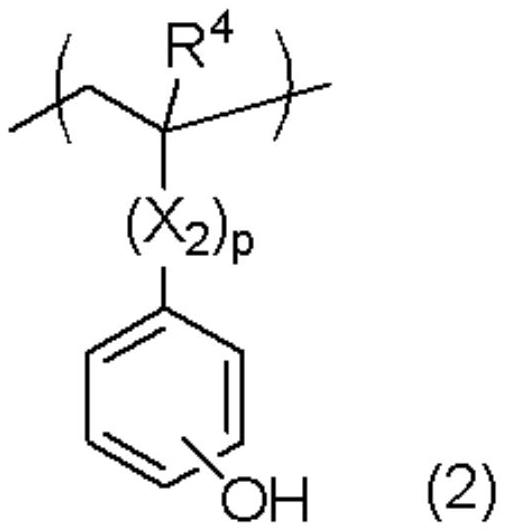

[0432] [chem 64]

[0433]

Synthetic example 1

[0434] [Synthesis example 1] Synthesis of polyimide resin (A1)

[0435] In a 1L flask equipped with a stirrer and a thermometer, add 2,2-bis(3-amino-4-hydroxyphenyl)hexafluoropropane (6FAP) 30g (81.9mmol), 4-aminophenol (PAP) 0.9g (8.6 mmol), N-methyl-2-pyrrolidone 125g, stirred and dissolved at room temperature. Then, at room temperature, 26.7 g (86.2 mmol) of 3,3',4,4'-oxydiphthalic dianhydride (s-ODPA) dissolved in 270 g of N-methyl-2-pyrrolidone was added dropwise The resulting solution was stirred at room temperature for 3 hours after the dropwise addition. Thereafter, 40 g of xylene was added to the reaction liquid, and heating and reflux was performed for 3 hours while removing generated water to the outside of the system at 170°C. After cooling to room temperature, the reaction solution was added dropwise into 2 L of ultrapure water with stirring, and the precipitate was separated and filtered, washed with water, and dried under reduced pressure at 40°C for 48 hours,...

Synthetic example 2

[0436] [Synthesis example 2] Synthesis of polyimide resin (A2)

[0437] Replace 30 g (81.9 mmol) of 2,2-bis(3-amino-4-hydroxyphenyl) hexafluoropropane (6FAP) in Synthesis Example 1 with 2,2-bis(3-amino-4-hydroxyphenyl) ) propane (BAP) 21.2g (81.9mmol), and the polyimide resin (A2) was obtained by the same prescription. When the molecular weight of the polymer was measured by GPC, the weight average molecular weight was 34,000 in terms of polystyrene.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com