Pressure detection system and method for membrane pump

A detection system and detection method technology, applied in the direction of pump testing, liquid displacement machinery, machine/engine, etc., can solve the problems of poor quality of diaphragm pump products, damage to electrical contacts, cost loss, etc., to protect mechanical performance, Reduced operating frequency and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

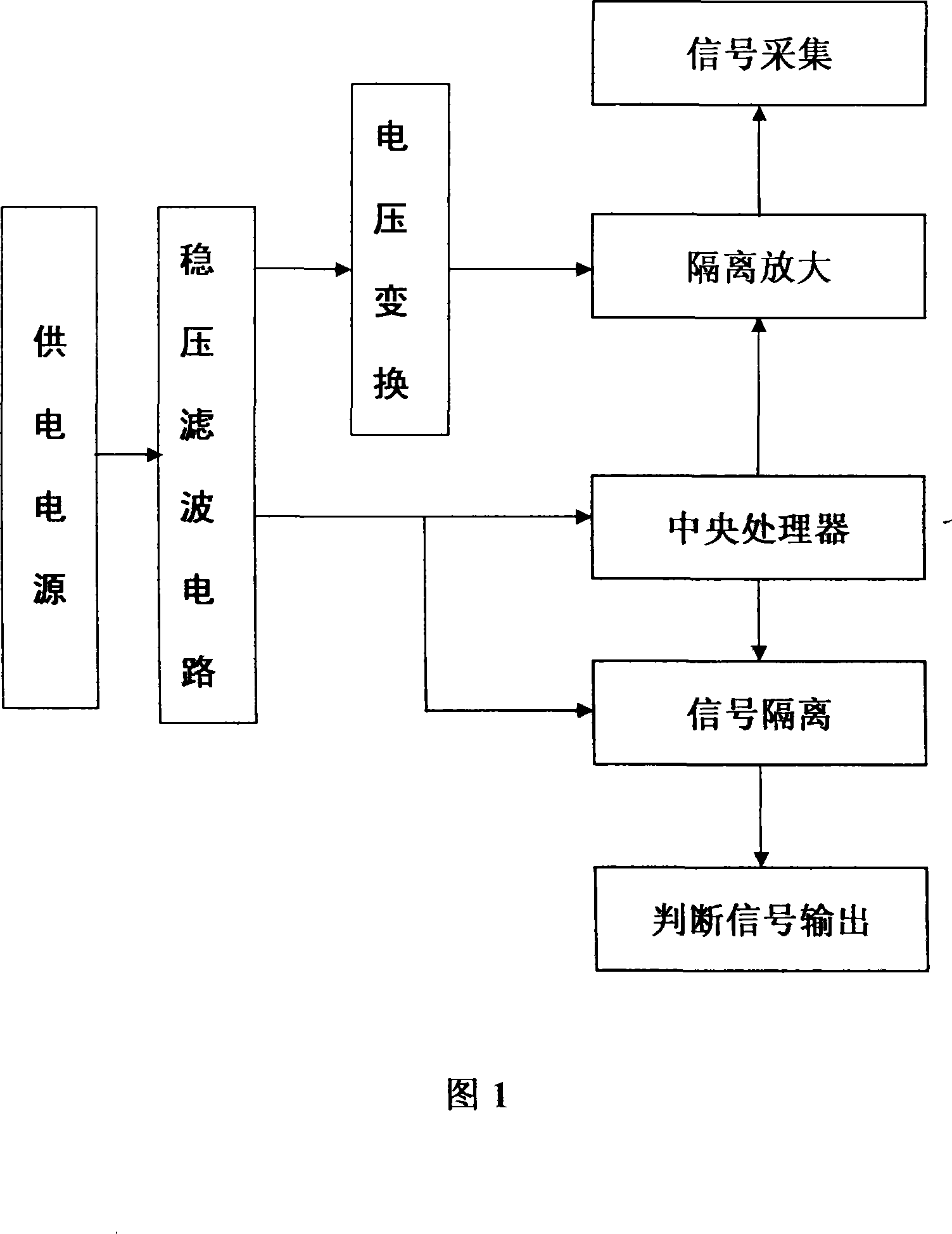

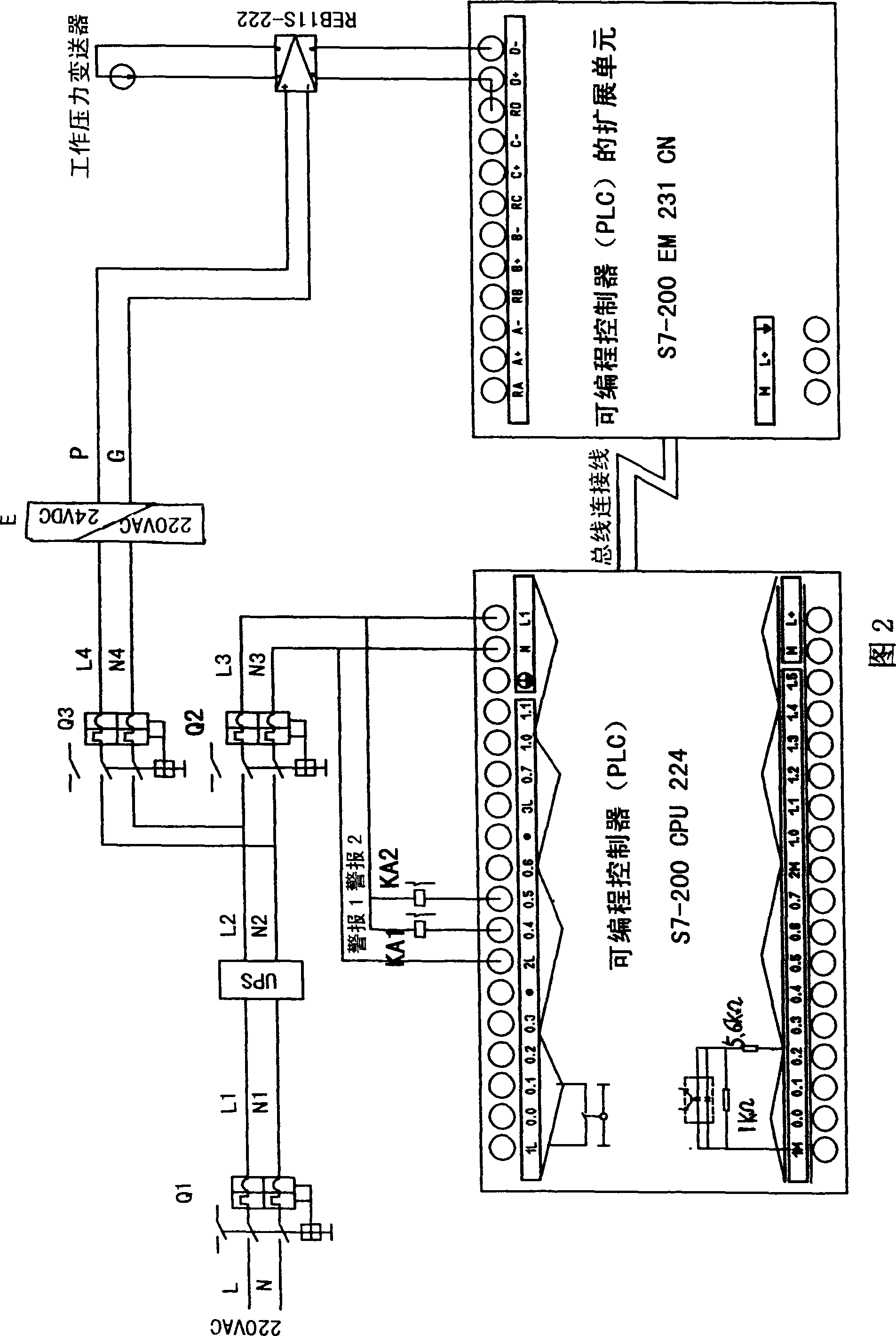

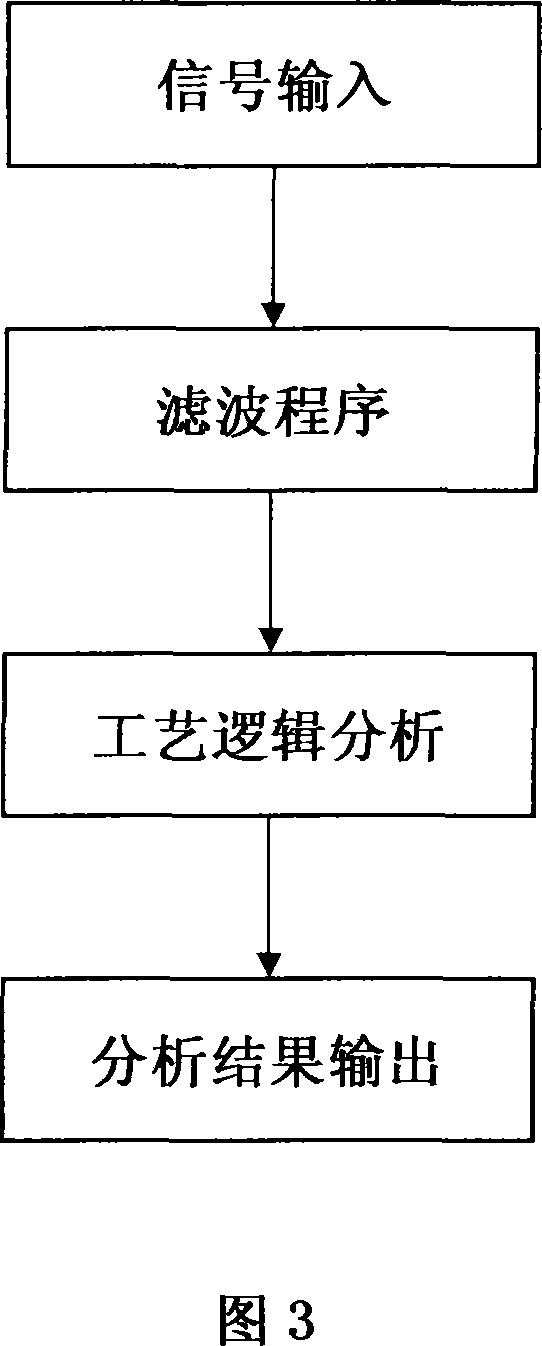

[0028] The 4-20mA electrical signals detected by the air pressure, working pressure, and propulsion hydraulic transmitters are electrically processed, and then the alarm signal is output after being processed by filtering technology and limit value deviation. The processed alarm output, especially the high signal of working pressure, reflects the real alarm information after eliminating the fluctuation. The installation position of the detection element for the working pressure of the diaphragm pump and the similar sine wave working mode of the diaphragm pump determine the fluctuation of the detected signal, and the fluctuation amplitude is affected by the pipeline pressure, feeding pressure and stroke frequency, slurry state, one-way It may be different due to the influence of various conditions such as the valve state. Therefore, it often occurs that the peak value of the fluctuation exceeds the limit value, but this peak value is not representative and has no practical sign...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com