Threaded joint for an oil-well tubing

A technology for threaded connectors and oil well pipes, applied in threaded connections, pipes/pipe joints/pipe fittings, drill pipes, etc., can solve the problems of unguaranteed increase in the service life of connectors, low service life, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

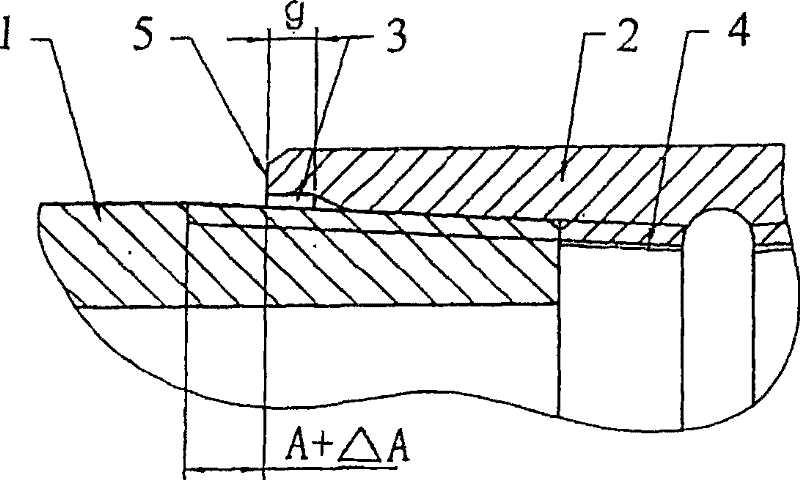

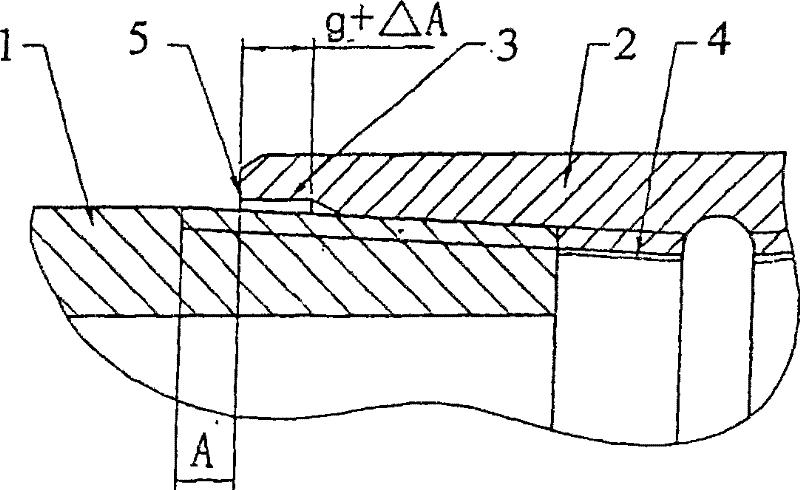

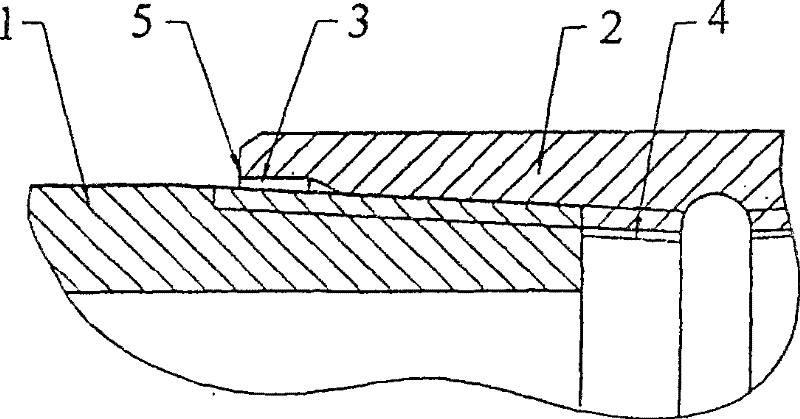

[0029] Threaded connector of the present invention ( figure 1 ) includes an externally threaded element 1, such as an oil well pipe or a reducer, hereinafter also referred to as a nipple; and an internally threaded element 2 matching the externally threaded element, such as a joint or a reducer, hereinafter also referred to as a joint. The entry section of the connection 2 has a cylindrical counterbore 3 . The diameter of the counterbore is slightly larger than the diameter of the unthreaded part of the nipple 1 . A coating 4 applied by a diffusion powder galvanizing method is provided on the threaded portion of the joint. The thickness of the coating 4 is generally in the range of 15 to 30 μm, but can also be even thicker—up to 50 μm. A corrosion-resistant phosphate coating with a thickness of a few microns is applied over the galvanized coating. The threaded surface of the nipple 1 is either uncoated or a standard aggressive phosphate coating of 2 to 3 μm thickness is app...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com