Combined roller bed

A technology of conveying roller table and conveying roller, which is applied in the field of conveying roller table and combined conveying roller table, which can solve the problems of single function of conveying roller table, occupying a large workshop area, and increasing cost investment, so as to achieve low maintenance cost and improve production efficiency , the effect of compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

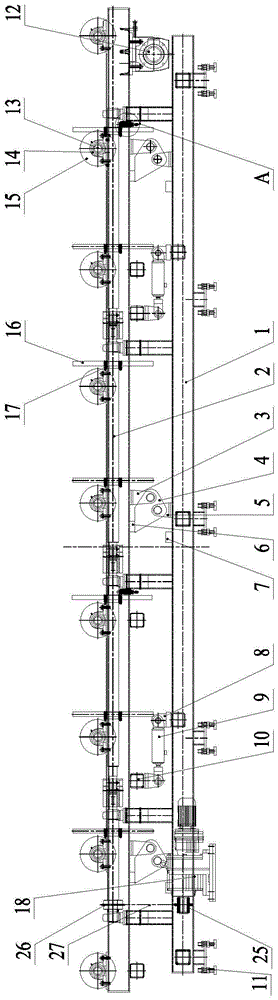

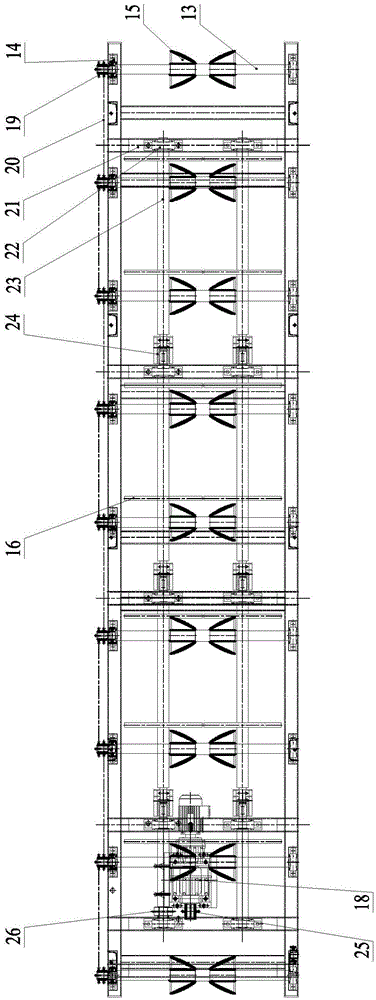

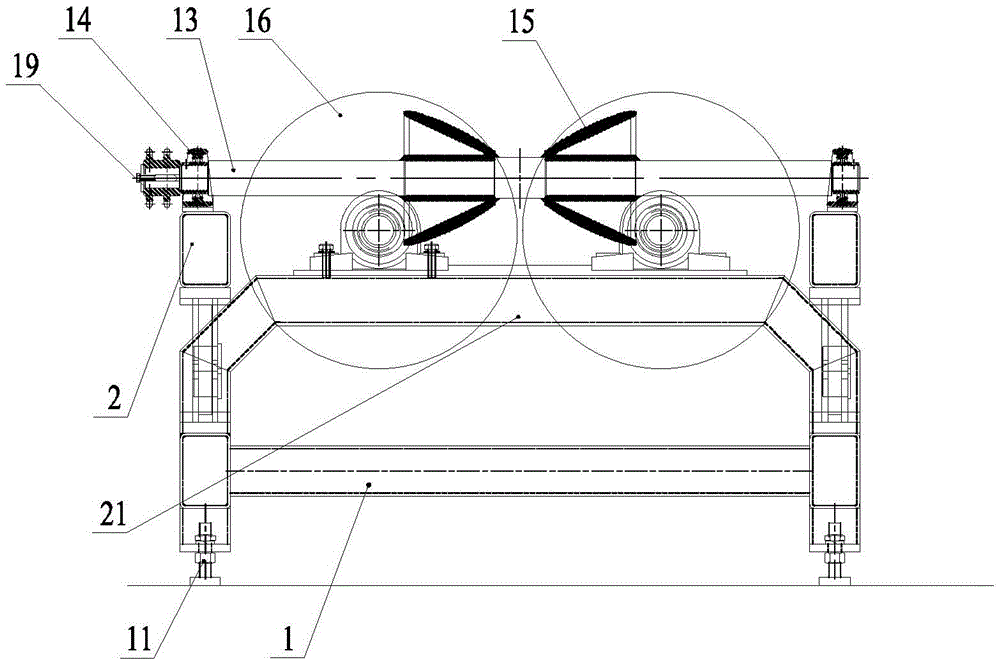

[0021] The present invention will be further described below in conjunction with specific drawings and embodiments.

[0022] As shown in the figure: the combined conveying roller table in the embodiment is mainly composed of a base 1, a floating frame 2, a first connection seat 3, a guide connection plate 4, a second connection seat 5, a first limit block 6, a second limit block Block 7, oil cylinder seat 8, oil cylinder 9, connecting seat 10, adjusting bolt 11, first reducer 12, conveying roller 13, first belt seat bearing 14, tapered conveying cylinder 15, friction wheel 16, expansion sleeve 17, Second reducer 18, double row sprocket 19, transmission chain 20, support frame 21, second belt seat bearing 22, rotating shaft 23, shaft coupling 24, active rotation sprocket 25, driven sprocket 26, rotation drive Chain 27, connecting piece 28, depression bar 29, top 30, adjustment nut 31, limit nut 32 and spring 33 etc. are formed.

[0023] Such as Figure 1~Figure 3 As shown, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com