A room-type bag packing and shipping equipment

A kind of equipment and bag technology, which is applied in the field of room-type bag packing and shipping equipment, can solve the problems of package damage of bulk materials, many manpower and material resources, and high work intensity, so as to improve the operation speed and quality, and improve the transportation efficiency , the effect of increasing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

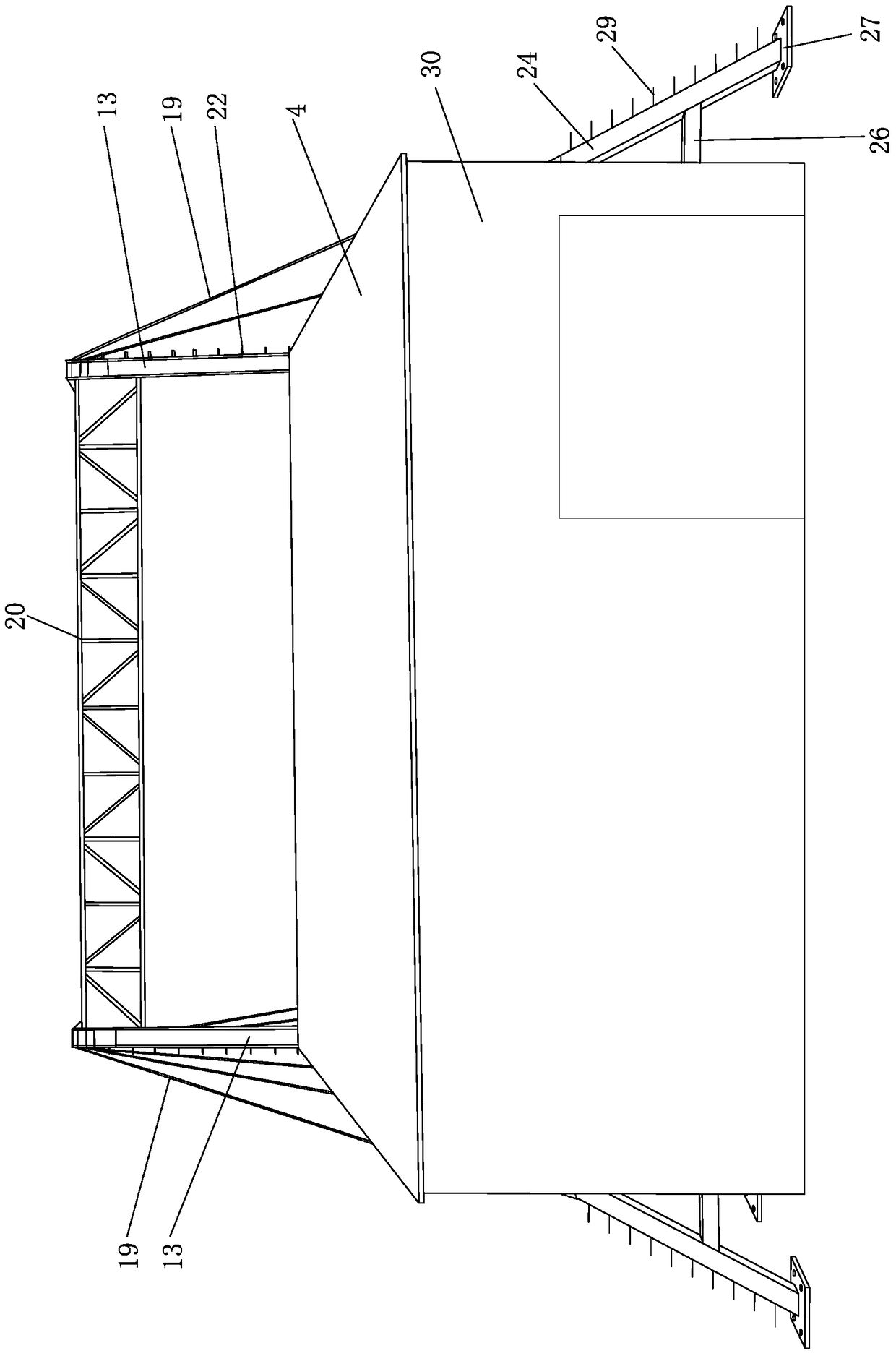

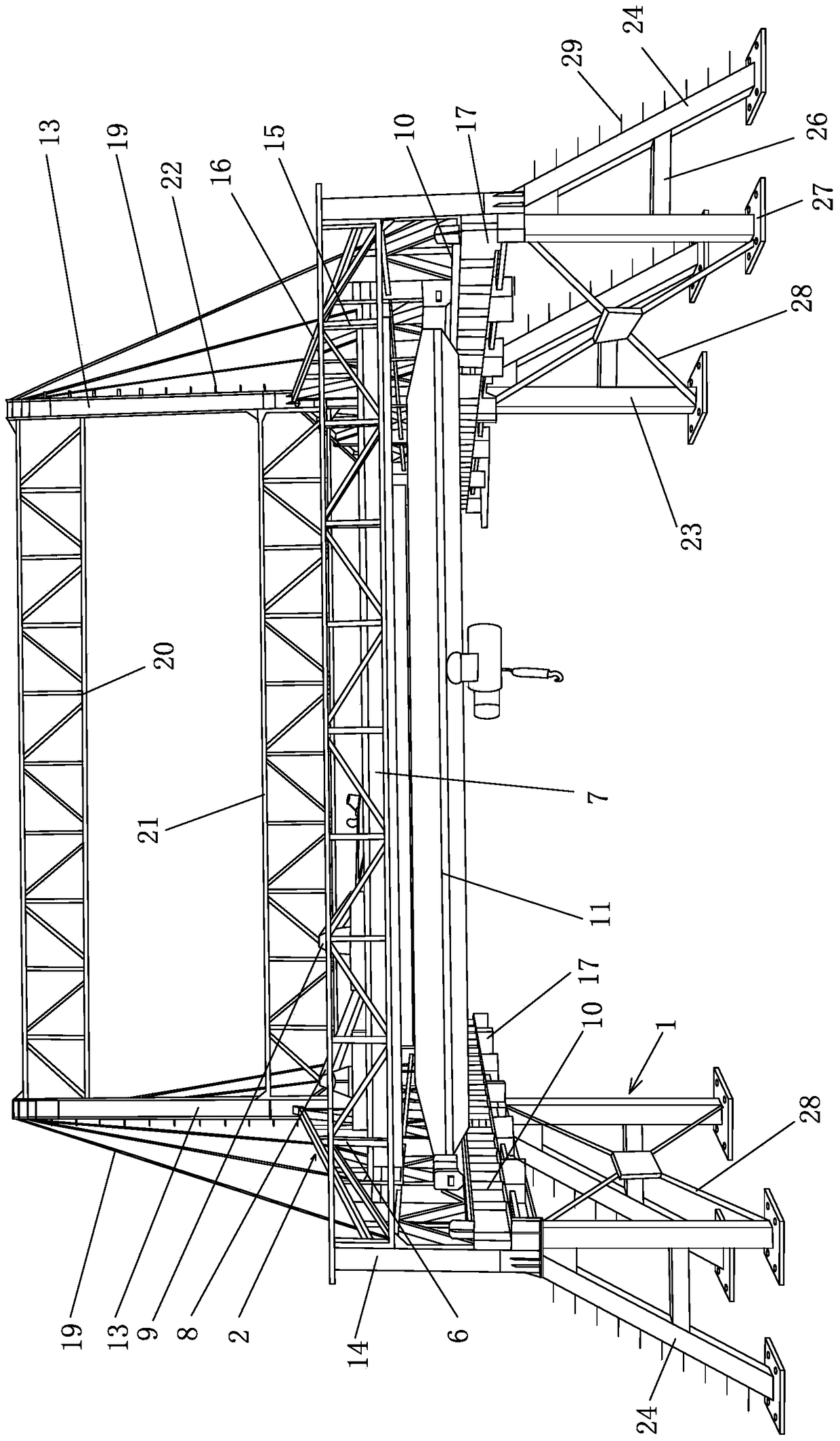

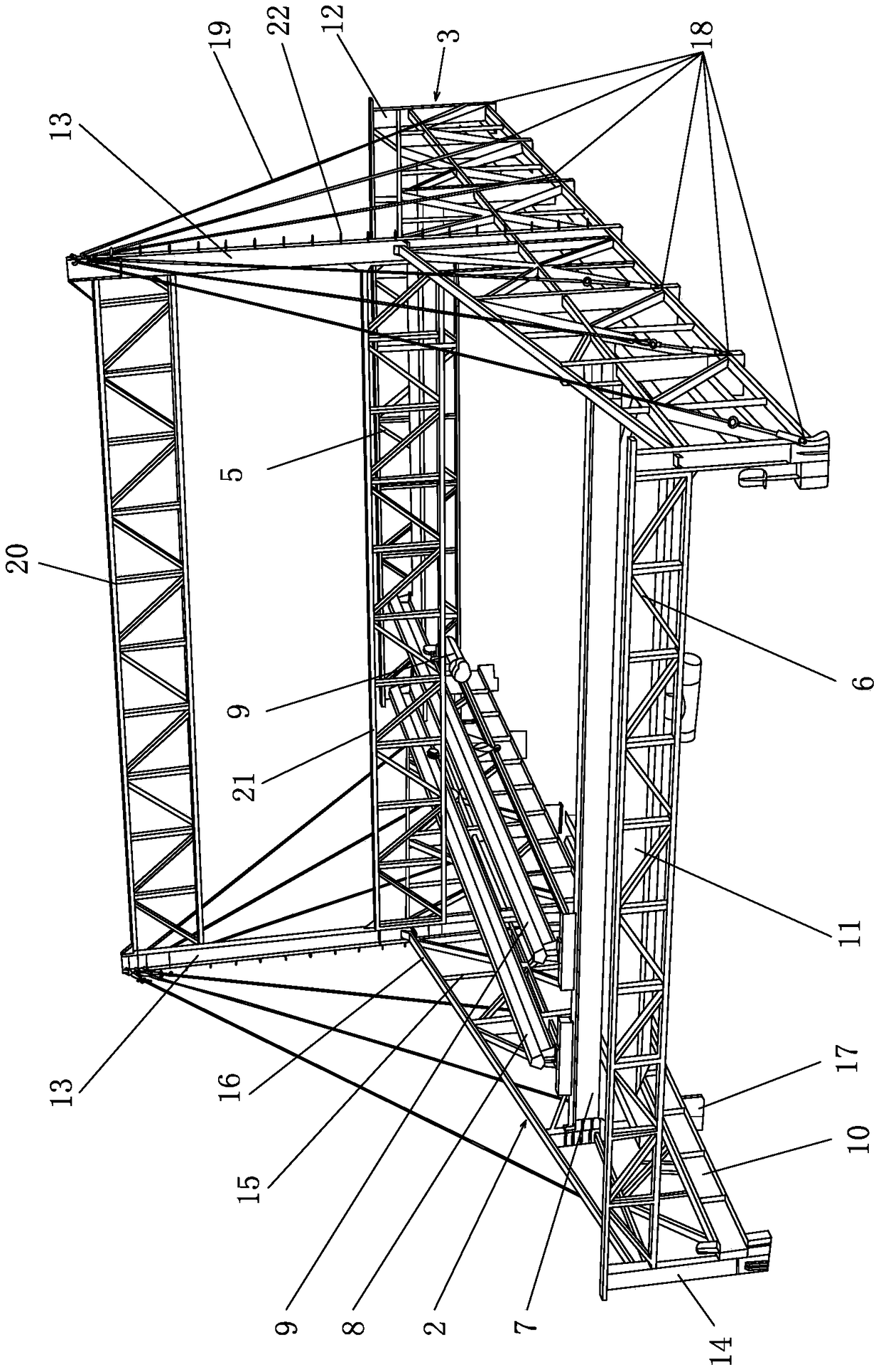

[0030] The present invention will be further described below with specific embodiments, referring to figure 1 -5:

[0031] A room-type bag bundling and shipping equipment includes a left and right column foot assemblies 1 arranged at intervals, more than two column foot assemblies 1 are arranged on each side, and a left column foot assembly 1 is arranged with a The left vertical beam assembly 2 and the right vertical beam assembly 1 are provided with a right vertical beam assembly 3. The front ends of the left vertical beam assembly 2 and the right vertical beam assembly 3 are suspended in the air. A roof 4 is arranged between the upper planes of the right vertical beam assembly 3. The iron tile roof is adopted in this embodiment, and the front and rear ends of the left vertical beam assembly 2 and the right vertical beam assembly 3 pass through respectively. The front connecting beam 5 and the rear connecting beam 6 are connected, and the left vertical beam assembly 2 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com