Ash discharge equipment and ash discharge method for solid-state ash discharge gasifier

A technology of solid-state slag discharge and slag discharge equipment, which is applied in the field of coal gasification, can solve the problems of low efficiency, ash lock cannot realize continuous slag discharge, etc., and achieve the effect of reducing impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

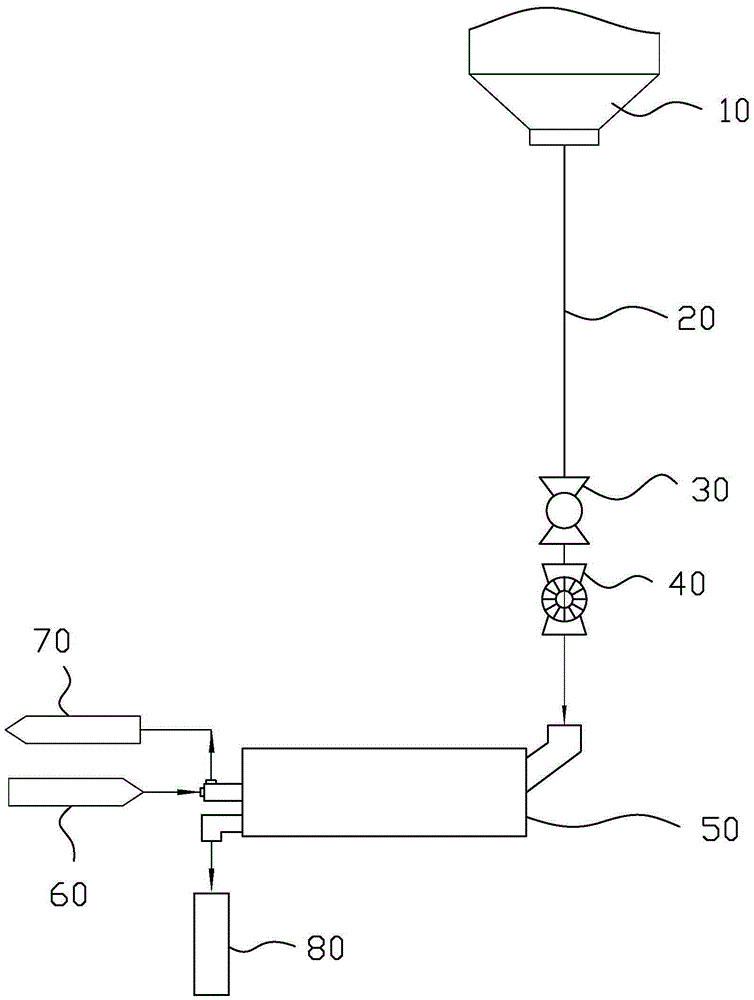

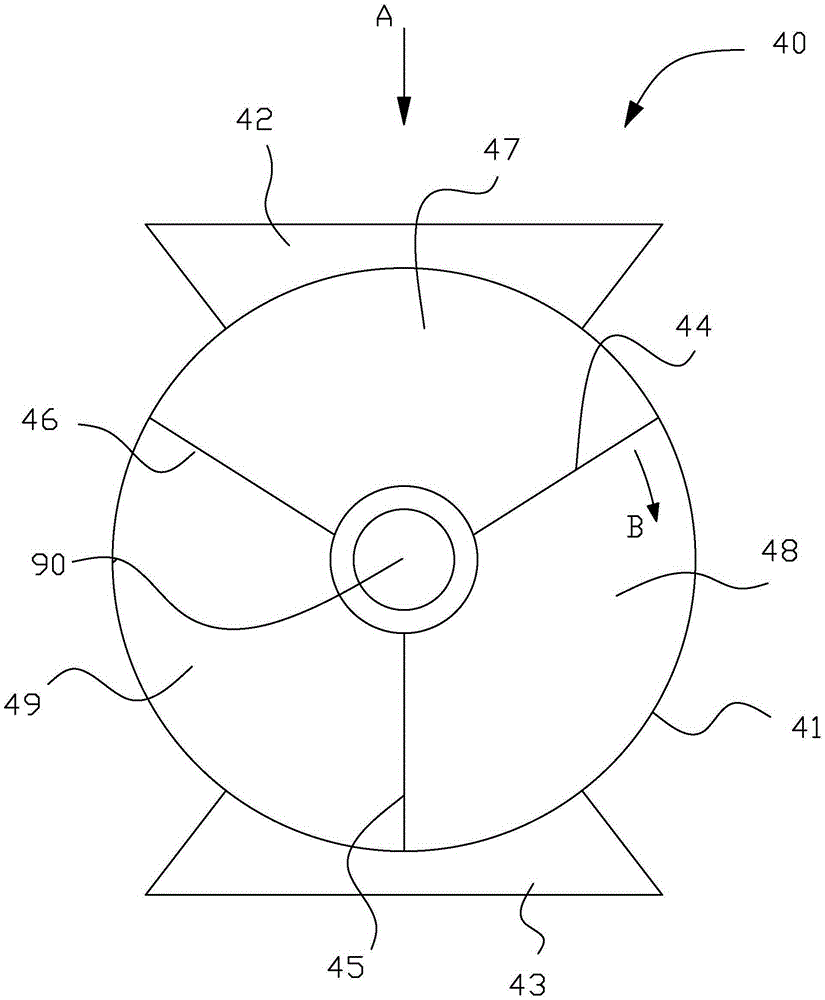

[0020] Referring now to the accompanying drawings, the schematic scheme of the slagging equipment of the solid-state slagging gasifier disclosed in the present invention will be described in detail. Although the drawings are provided to illustrate certain embodiments of the invention, the drawings are not necessarily to scale of particular embodiments and certain features may be exaggerated, removed, or partially sectioned to better illustrate and explain aspects of the invention. public content. Appearances of the phrase "in the drawings" or similar terms in the specification do not necessarily refer to all drawings or examples.

[0021] Certain directional terms used hereinafter to describe the drawings, such as "inner," "outer," "left," "right," "upward," "downward," and other directional terms, are to be understood as has its normal meaning and refers to those directions in which the drawings are normally viewed. Unless otherwise specified, the directional terms describe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com