Lattice brick with 19 lattices and lattice hole diameter of 25 mm and stacking method

A checker brick and hole diameter technology, applied in the regenerator of high-temperature heat storage exchangers and heat exchange furnaces, 19-hole 25mm grid hole diameter checker bricks and stacking, high-efficiency and low-cost regenerator field, can solve manufacturing difficulties Advanced problems, to achieve the effect of low production difficulty, uniform gas flow field, and reduced use cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

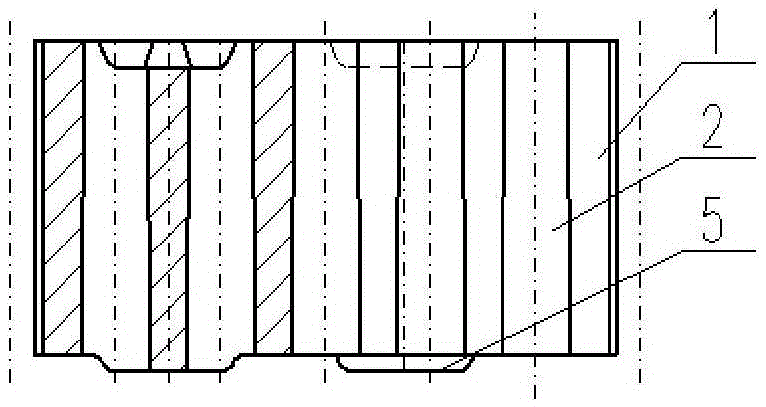

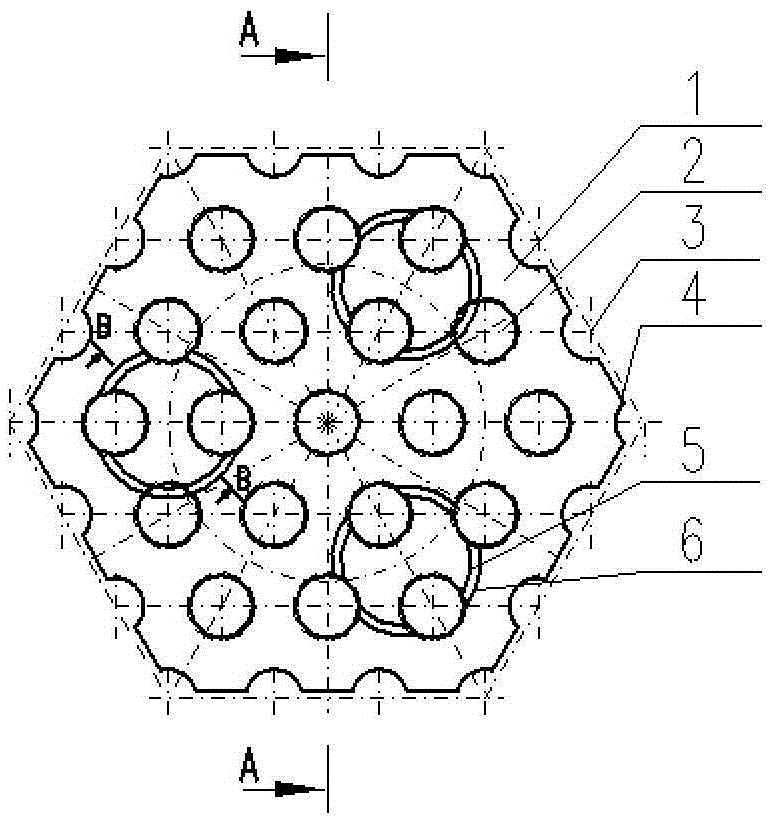

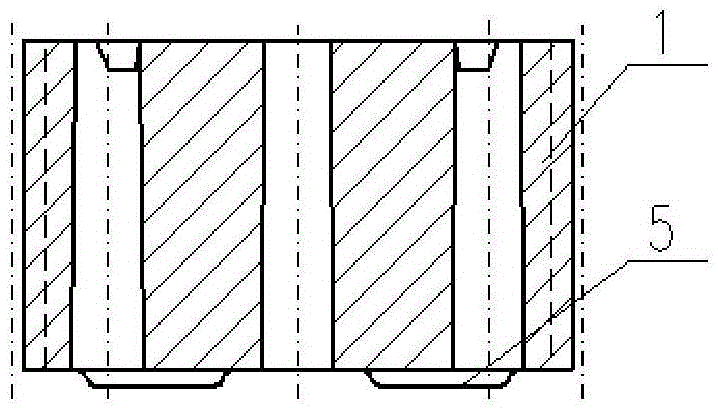

[0016] Figure 1 to Figure 5 is a specific embodiment of the present invention

[0017] A checkered brick with 19 holes and 25mm grid hole diameter, a regular hexagonal prism brick body 1 and 19 complete circular through holes 2 in the vertical direction distributed on the brick body, 12 semicircular through holes 3, and 6 1 / 3 circular through hole 4, the diameter of the circular through hole is 25mm, and the complete circular through hole 2 is divided into three rings inside and outside the center of the checker brick, and the 12 through holes in the outermost ring are parallel to the six hexagonal prisms. According to the average distribution of 3 through holes on each side, the angle between the center of the hole and the center of the checker brick is divided into 30°, and the 6 through holes in the middle ring are divided equally every 60° in the circumferential direction. The inner ring is a circular through hole located in the very center of the brick body 1. There are...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com