An overflow loss recovery system based on hydraulic motor and its control method

A technology of hydraulic motor and recovery system, which is applied in fluid pressure actuation system components, fluid pressure actuation system testing, servo motors, etc. It can solve the pressure difference loss at the valve port, the accumulator pressure cannot be actively controlled, and it is difficult to achieve high efficiency Energy recovery and other issues to achieve efficient energy recovery, improve pressure control accuracy and solve the effects of differential pressure loss at the overflow valve port

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The invention will be further described below in conjunction with specific embodiments:

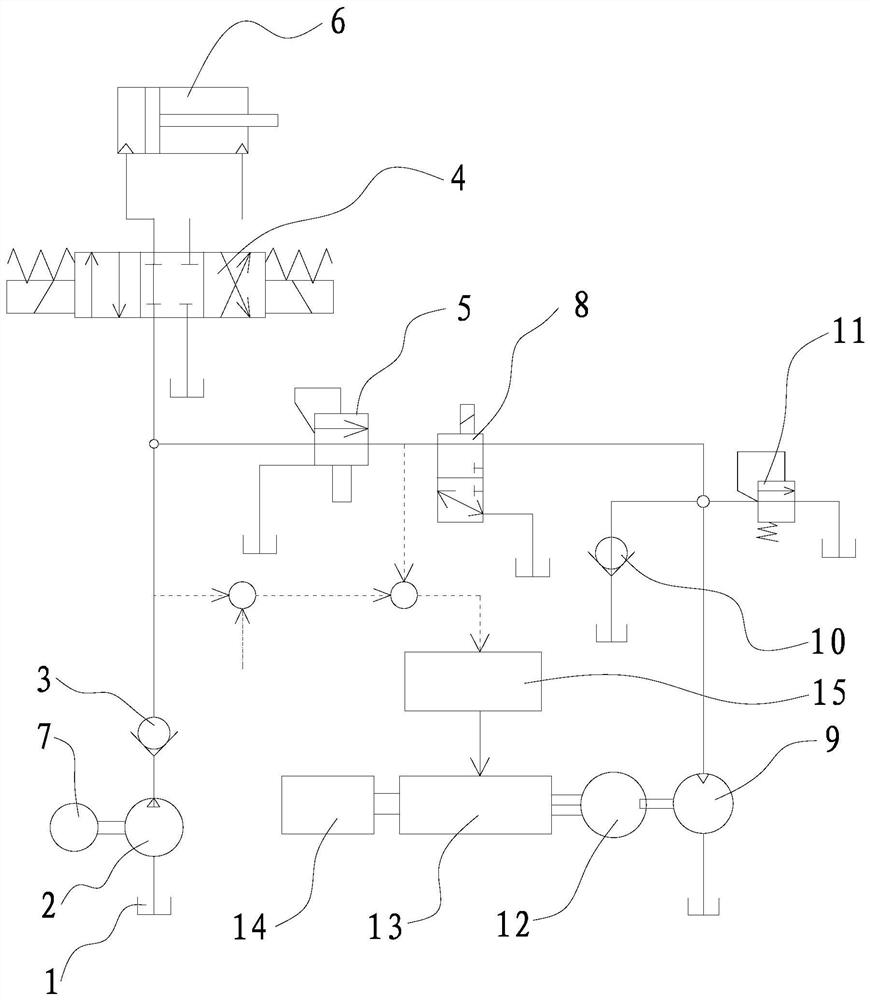

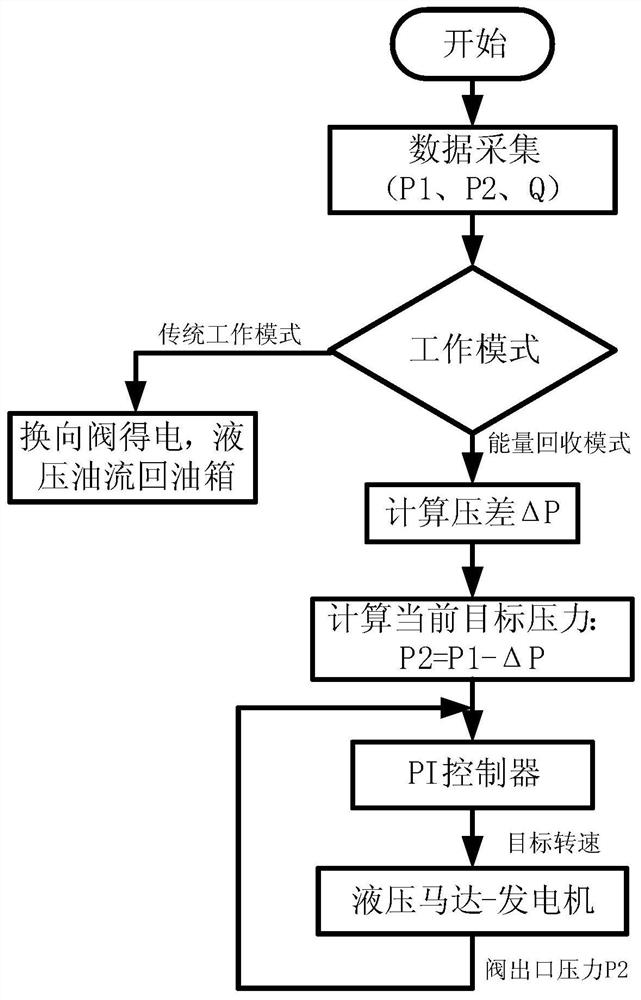

[0030] like figure 1 As shown, this embodiment provides an overflow loss recovery system based on a hydraulic motor, including an oil tank 1, a main pump 2 connected with the oil inlet and the oil tank, and a first pump connected with the oil inlet and the oil outlet of the main pump 2. The reversing valve 3 and the oil inlet are respectively connected with the first reversing valve 4 and the first relief valve 5 which are connected with the oil outlet of the first one-way valve 3 , and the hydraulic cylinder 6 which is connected with the first reversing valve 4 . Among them, the main pump 2 can be a quantitative pump or a variable displacement pump, which can be selected according to actual needs; the main pump 2 is driven by the driving motor 7. Specifically, the input shaft of the main pump 2 and the output shaft of the driving motor 7 are connected through a coupling. shaft co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com