One-bath garment dyeing technology of reduced dye and water-soluble sulfur dye

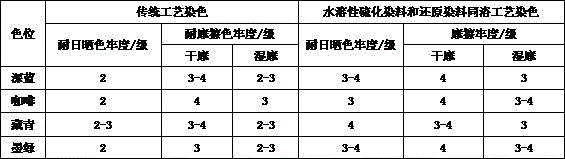

A sulfur dye and garment dyeing technology, which is applied in dyeing, textiles and papermaking, can solve problems such as light fastness, poor color fastness to rubbing, unsightly, easy to fade, etc., to improve international competitiveness, Improvement of physical indexes and complete chromatogram

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Ready-made garments made of semi-bleached fabric; specification: 40×40 / 133×72; composition: 100% cotton.

[0045] The above-mentioned garments are put into the garment dyeing machine, and the following procedures are carried out in sequence:

[0046] Pretreatment process

[0047] Add pretreatment working reagents to the garment dyeing machine at room temperature, raise the temperature to 95°C at a heating rate of 2°C / min, and react for 15 minutes; cool down to 85°C at a cooling rate of 2°C / min, wash with water at 85°C for 5 minutes; add glacial acetic acid Adjust the pH value to 6.5; wash with water at room temperature for 10 minutes;

[0048] The pretreatment working reagents include:

[0049] Soda ash 4g / L;

[0050] Transfar refining agent TF-1085g / L.

[0051] The g / L is the number of grams of each component of the working reagent added to the liquid in the garment dyeing machine per liter (the same below).

[0052] dyeing process

[0053] Add dyeing reagents to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com