System and method for cantilever beam heavy-duty test of self-elevating drilling platform

A technology for drilling platform and heavy load test, applied in the direction of joists, girders, trusses, etc., can solve problems such as platform damage, and achieve the effect of improving work efficiency and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

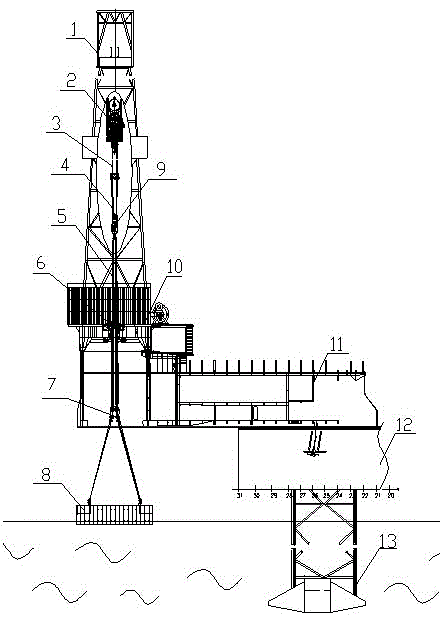

[0032] The present invention is a jack-up drilling platform cantilever beam heavy load test system, such as figure 1 As shown, it includes a main hull 12 supported by legs 13 above the sea level, a cantilever beam 11 horizontally located on the main hull 12 and extending to the sea level, a drilling platform 10 at the end of the cantilever beam 11 and a derrick 1, The top drive 2 located on the upper part of the derrick 1 and the ballast water barge 8 connected to the top drive 2 floating on the sea level; the drilling platform 10 is provided with a stand area simulating the actual weight; connected.

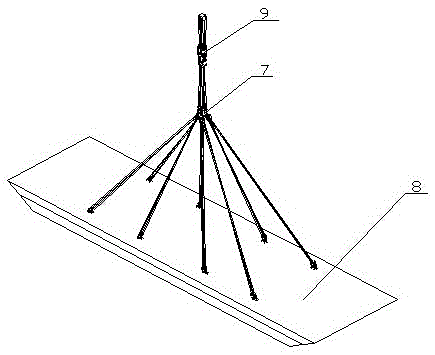

[0033] Such as image 3 As shown, there are eight lifting points arranged in a balanced manner on the barge 8, and the lifting points are arranged in two rows symmetrically along the long axis of the barge 8. Between the barge 8 and the top drive 2, there is a device for converting the eight-point hoisting into two-end hoisting. specific tooling. Such as Figure 5 As shown, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com