A construction method of assembled formwork for side walls of long-distance underground passages

A construction method and technology of underground passages, applied in artificial islands, water conservancy projects, underwater structures, etc., can solve the problems that formwork materials cannot be recycled for multiple times, affect the quality of concrete structures, and have low degree of construction mechanization, etc., and achieve good promotion Value, high degree of mechanization, and the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

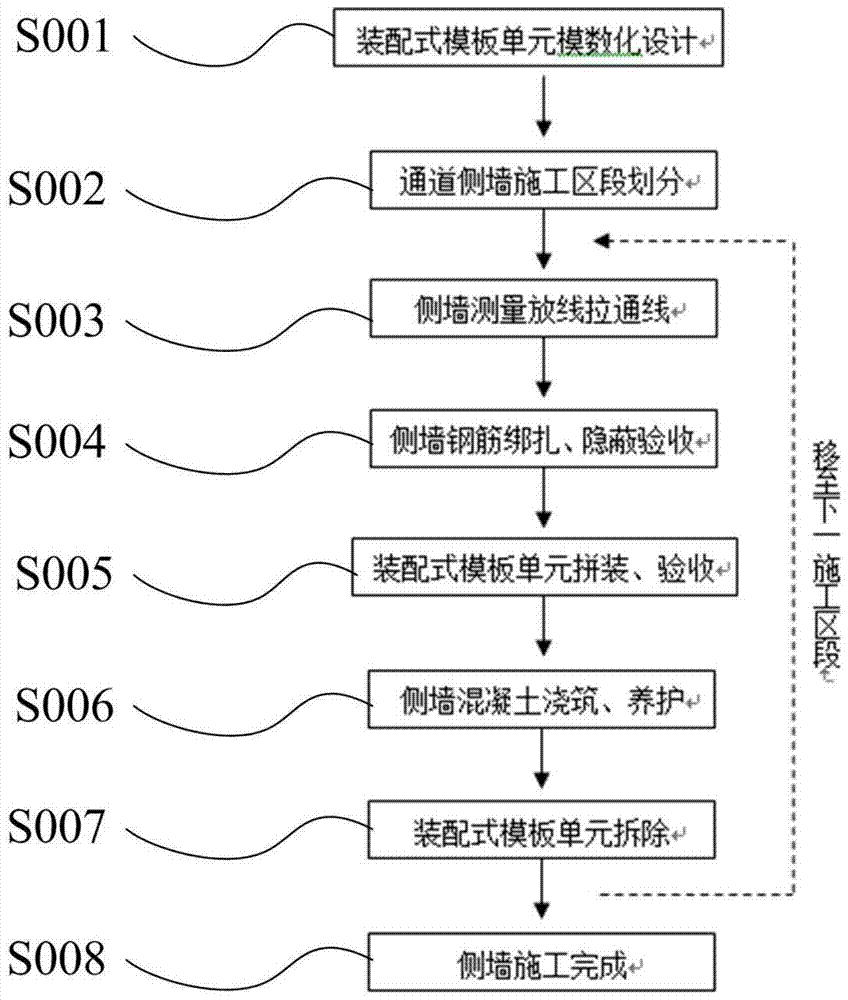

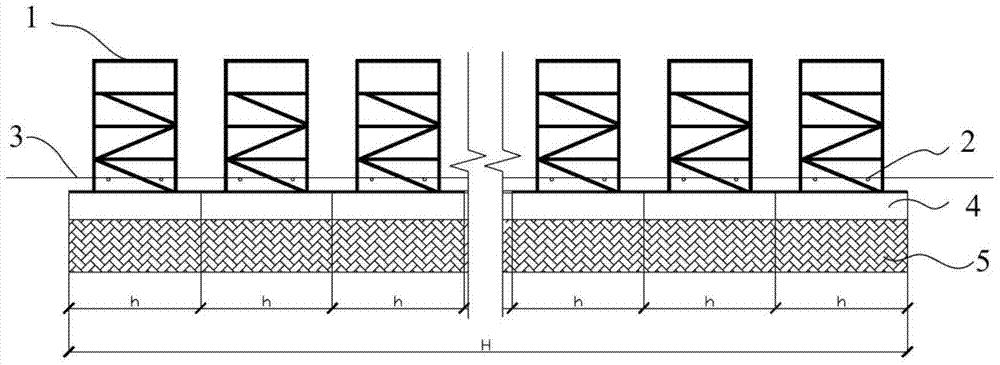

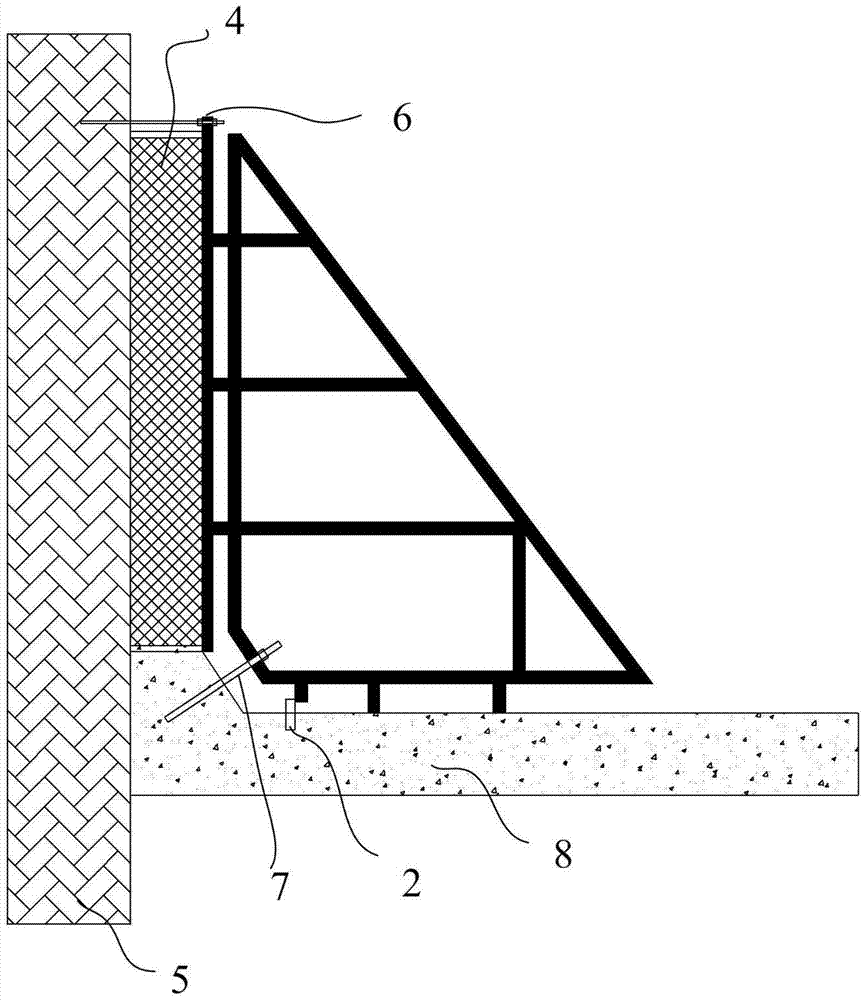

[0031] Such as Figure 1 to Figure 3 As shown, a long-distance underground passage side wall assembly type formwork construction method, the construction method includes the following steps:

[0032] S001: Carry out modular design to determine the size of the prefabricated formwork unit 1 according to the overall plane curve of the channel. The size of the prefabricated formwork unit 1 is mainly determined by using straight lines instead of curves to ensure the quality of the joints of the prefabricated formwork and realize the modular design of the prefabricated formwork system, thus overcoming the need for all-steel large formwork to be customized according to the size of the wall , lack of engineering versatility. In order to meet the design requirements, the height of the prefabricated formwork unit 1 at the junction of the bottom plate 8 and the side wall 4 is 10 cm higher than that of the side wall. The width h of the prefabricated formwork unit 1 is 2m, the height is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com