Locking wedge system as hatch lock for motor vehicles

A technology for locking wedges and hatch covers, which is applied in the field of locking wedge systems and can solve problems such as being difficult to open and no longer being able to be opened.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

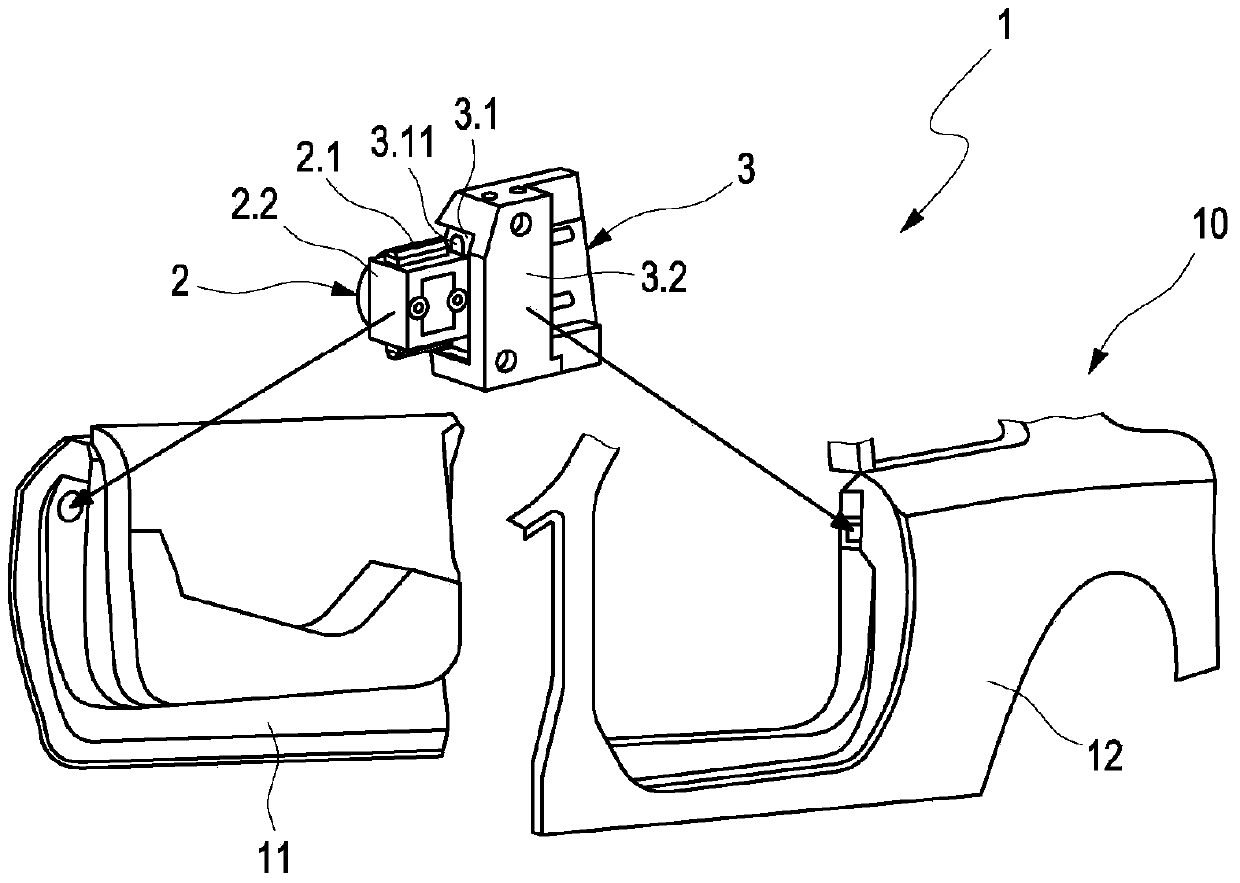

[0042] figure 1 Shown is a locking wedge system 1 known from DE 10 2012 011 420 A1, which assumes the function of a door lock for a door 11 of a body 10, said locking wedge system comprising a locking wedge module 2 and a holding block Module 3. The locking wedge module 2 is mounted on the lock side of the door 11 , while the retaining block module 3 is mounted on the door frame formed by the side wall frame 12 of the vehicle body 10 . When locking the vehicle door 11 , the locking wedge module 2 is coupled to the holding block module 3 , so that there is a non-positive connection between the vehicle door 11 and the side wall frame 12 of the vehicle body 10 . The detailed design and function of such a locking wedge system 1 are described in detail in the aforementioned document DE 10 2012 011 420 A1, the content of which is included in its entirety in this description.

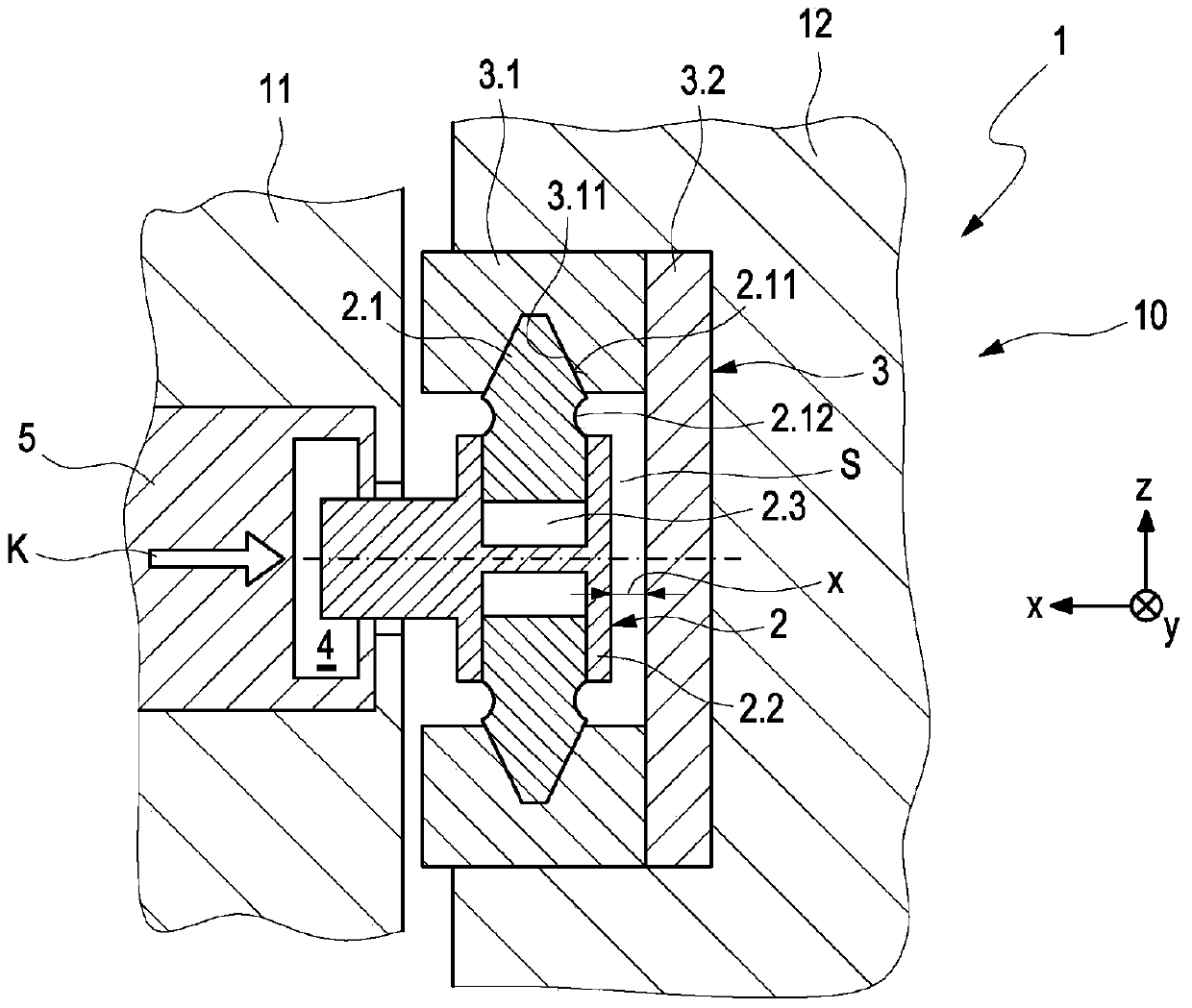

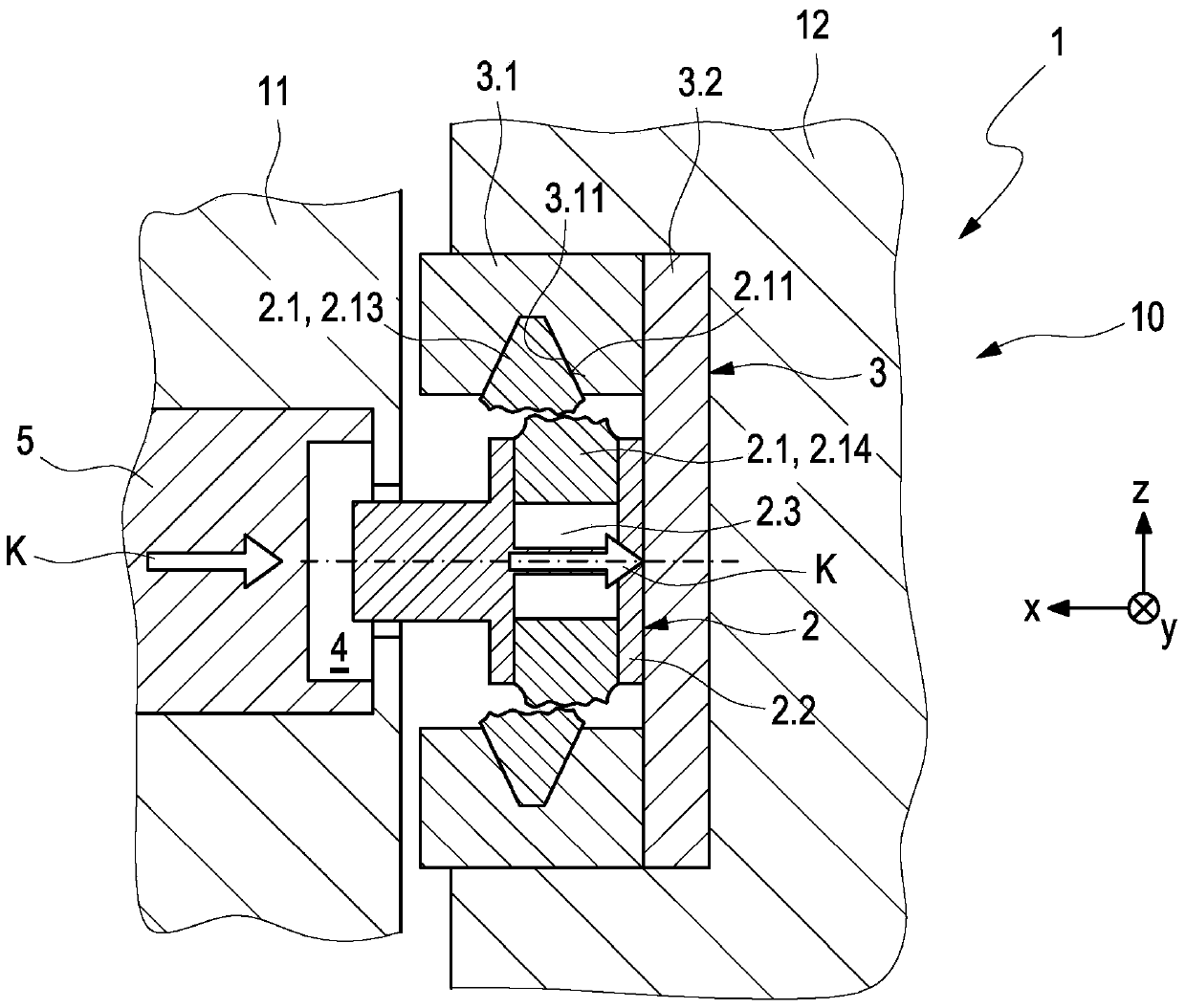

[0043] figure 2 The state of the locking wedge system 1 in which the locking wedge module 2 is coupled ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com