A kind of flexible artificial skin and its preparation method

An artificial skin and flexible technology, applied in the field of flexible artificial skin and its production, can solve the problems of affecting cell colonization and growth, insufficient artificial skin strength, aseptic inflammation, etc., to facilitate transportation and exchange, avoid toxic side effects, prolong effect of shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

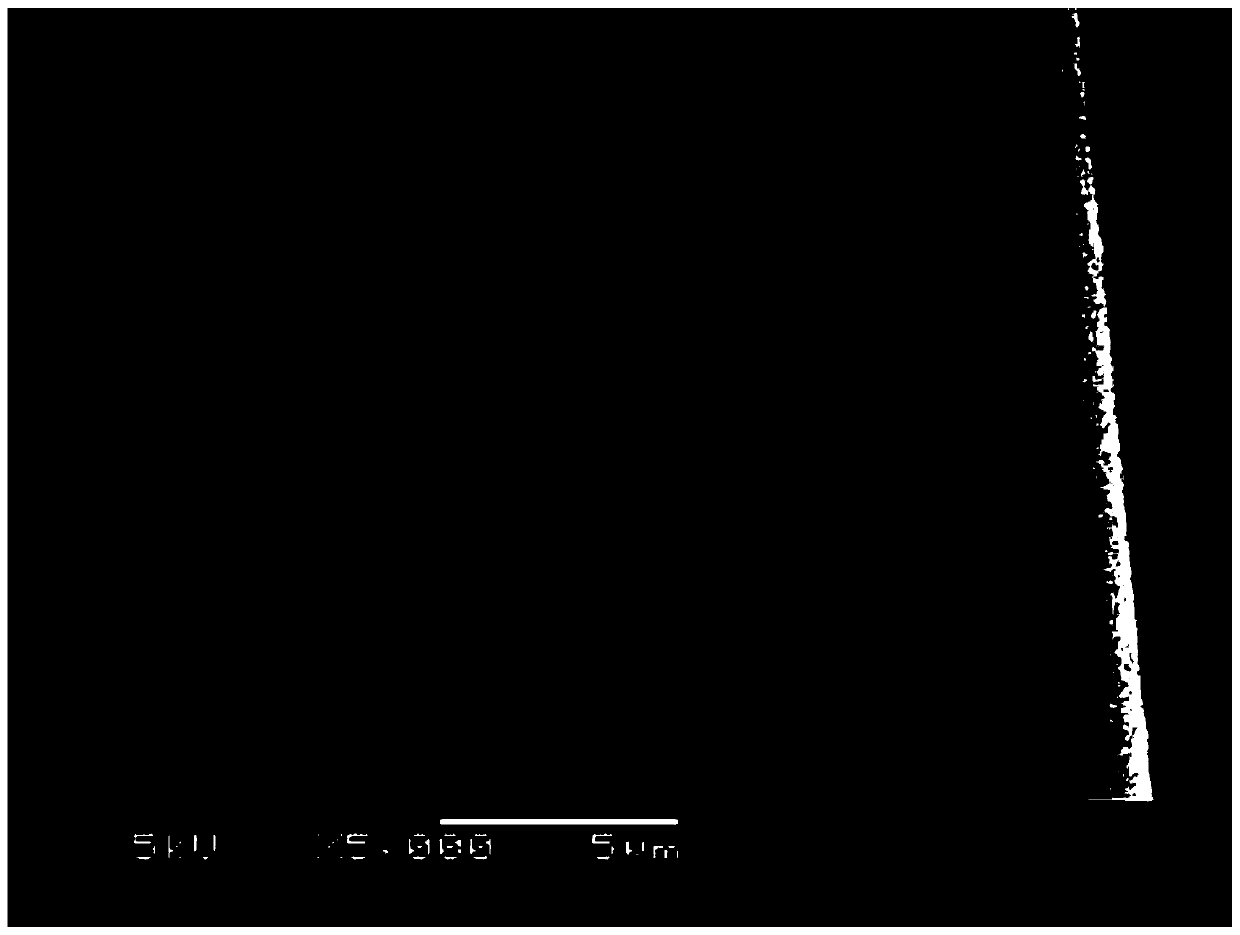

[0031] 1) Preparation of braided yarn: Take 2 strands of PLA filament with an average fineness of 8 tex, and twist the 2 strands of filament at 300 twists / m into a braided yarn.

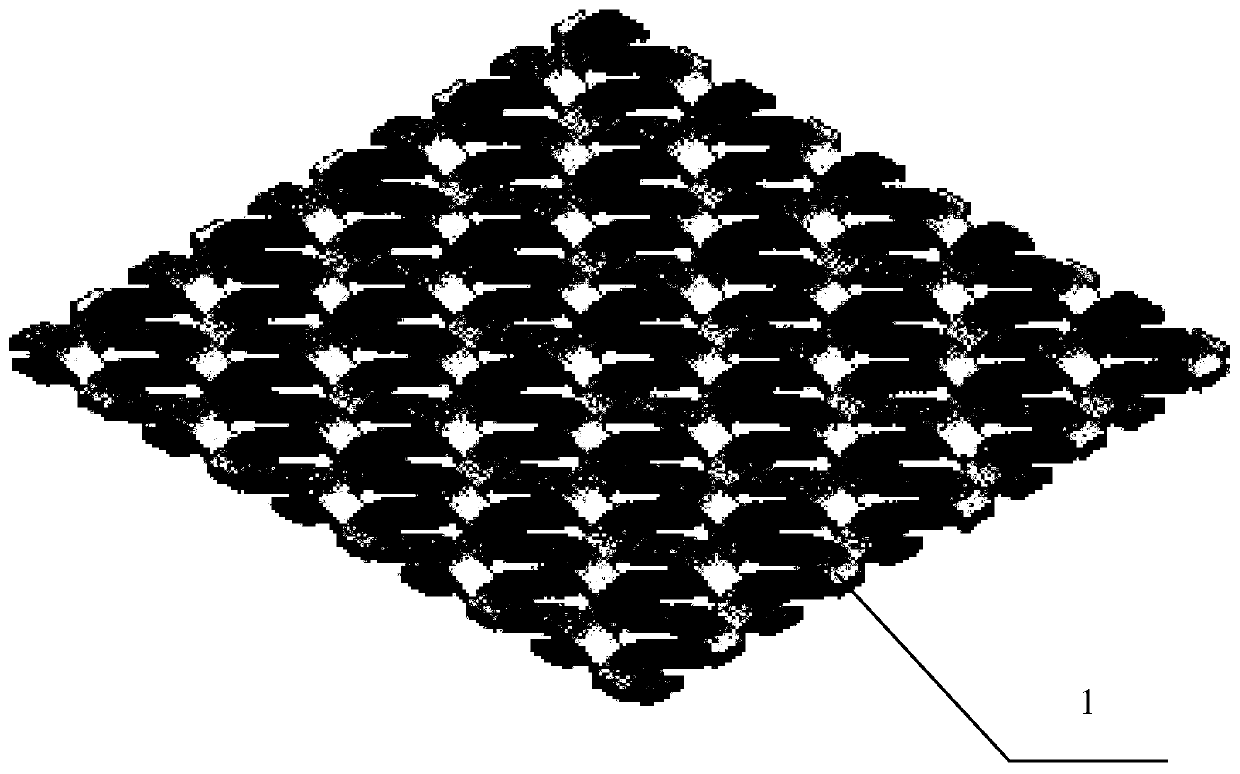

[0032] 2) Fabrication of the braided layer: The braided layer is made by the Heglis weaving process, with a porosity of 25% and a thickness of 300μm;

[0033] 3) Atmospheric pressure plasma treatment: the gas used is helium, the gas temperature is 90°C, the flow rate is 4L / min, and the treatment time is 4min;

[0034] 4) Configure the hydrogel solution: Take sodium hyaluronate and deionized water according to the molar ratio of 1:50 to configure the hydrogel solution, and mix the epidermal growth factor, nano silver ions and hydrogel materials according to 10:1:300 The molar ratio of the mixture is uniformly mixed;

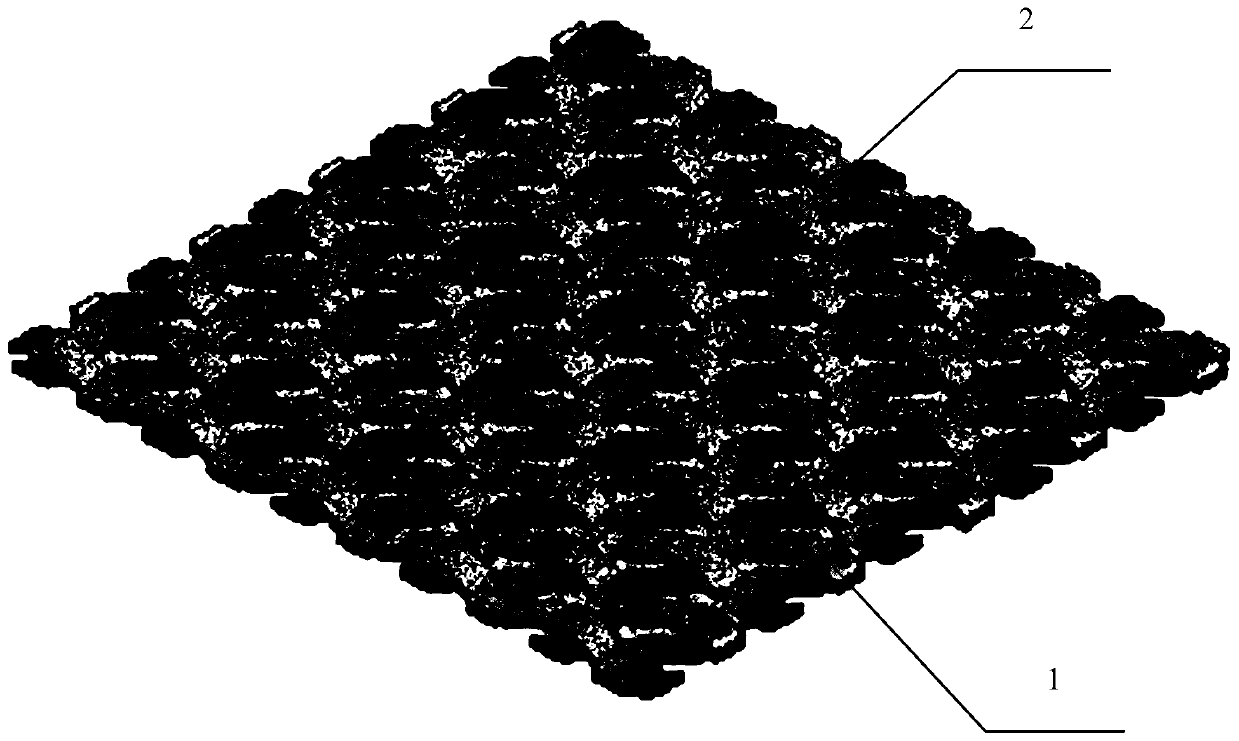

[0035] 5) The braided layer is coated with hydrogel: under aseptic conditions, the hydrogel solution is applied at 1.5 mg / cm 2 Coat evenly on the surface of the braided layer, then solidify at 4...

Embodiment 2

[0037] 1) Preparation of braided yarn: Take 2 strands of PGA filament with an average fineness of 10 tex, and twist the 2 strands of filament into a braided yarn at 250 twists / m.

[0038] 2) Fabrication of braided layer: the braided layer is fabricated by a two-dimensional triaxial weaving process with a porosity of 15% and a thickness of 400μm;

[0039] 3) Atmospheric pressure plasma treatment: The gas used is helium, the gas temperature is 100°C, the flow rate is 6L / min, and the treatment time is 6min;

[0040] 4) Configure the hydrogel solution: Take sodium hyaluronate and deionized water according to the molar ratio of 1:30 to prepare the hydrogel solution, and mix the epidermal growth factor, nano silver ions and hydrogel materials according to 10:1:400 The molar ratio of the mixture is uniformly mixed;

[0041] 5) The braided layer is coated with hydrogel: under aseptic conditions, the hydrogel solution is 1.0mg / cm 2 Coat evenly on the surface of the braided layer, then solidify...

Embodiment 3

[0043] 1) Preparation of braided yarn: take 3 strands of PLGA filament with an average fineness of 6 tex, and twist 3 strands of filament at 200 twists / m into a braided yarn.

[0044] 2) Fabrication of the braided layer: The braided layer is made by the Heglis weaving process, with a porosity of 30% and a thickness of 600μm;

[0045] 3) Atmospheric pressure plasma treatment: The gas used is oxygen, the gas temperature is 100°C, the flow rate is 8L / min, and the treatment time is 8min;

[0046] 4) Configure the hydrogel solution: Take sodium hyaluronate and deionized water according to the molar ratio of 1:40 to configure the hydrogel solution, and mix the epidermal growth factor, nano silver ions and hydrogel materials according to 10:1:500 The molar ratio of the mixture is uniformly mixed;

[0047] 5) The braided layer is coated with hydrogel: under aseptic conditions, the hydrogel solution is applied at 0.8 mg / cm 2 Coat evenly on the surface of the braided layer, then solidify at 4°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com