Mechanical connecting structure of shield machine sealing device

A technology of mechanical connection structure and sealing device, applied in mining equipment, earthwork drilling, tunnels, etc., can solve the problems of construction and surrounding environment, affecting normal excavation, separation of sand and pebbles, etc., to achieve stable and effective control and production efficiency The effect of high, low operational risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

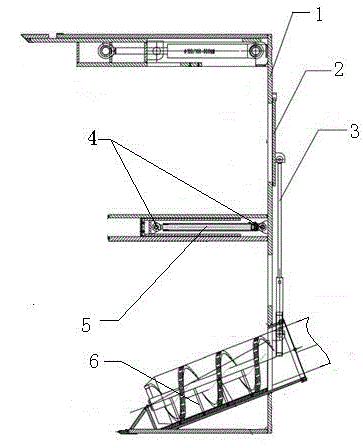

[0014] This embodiment provides a connection structure of the sealing device of the shield machine, which is characterized in that: the connection structure of the sealing device of the shield machine includes a shield machine partition (1), a sealing device partition (2), a hydraulic Cylinder A (3), hydraulic cylinder B (4), observation plate (5), conveyor (6);

[0015] Among them: the sealing device partition (2) and the observation plate (5) of the structure are both hinged with the shield machine partition (1) through the hydraulic cylinder, and the sealing device partition (2) is connected with the hydraulic cylinder A (3). The plate (5) is connected to the hydraulic cylinder B (4), and the shield machine partition (1) and hydraulic cylinder A (3) are connected to the delivery port of the conveyor (6) on the shield machine.

[0016] The observation plate (5) is vertically arranged with the sealing device partition (2) and the shield machine partition (1).

[0017] A hydr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com