Integrated Powertrain

A force shaft and engine technology, applied in the field of integrated powertrain, can solve the problems of serious fuel waste, low fuel combustion efficiency, and heavy weight, and achieve the effect of compact structure, high economic value, and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

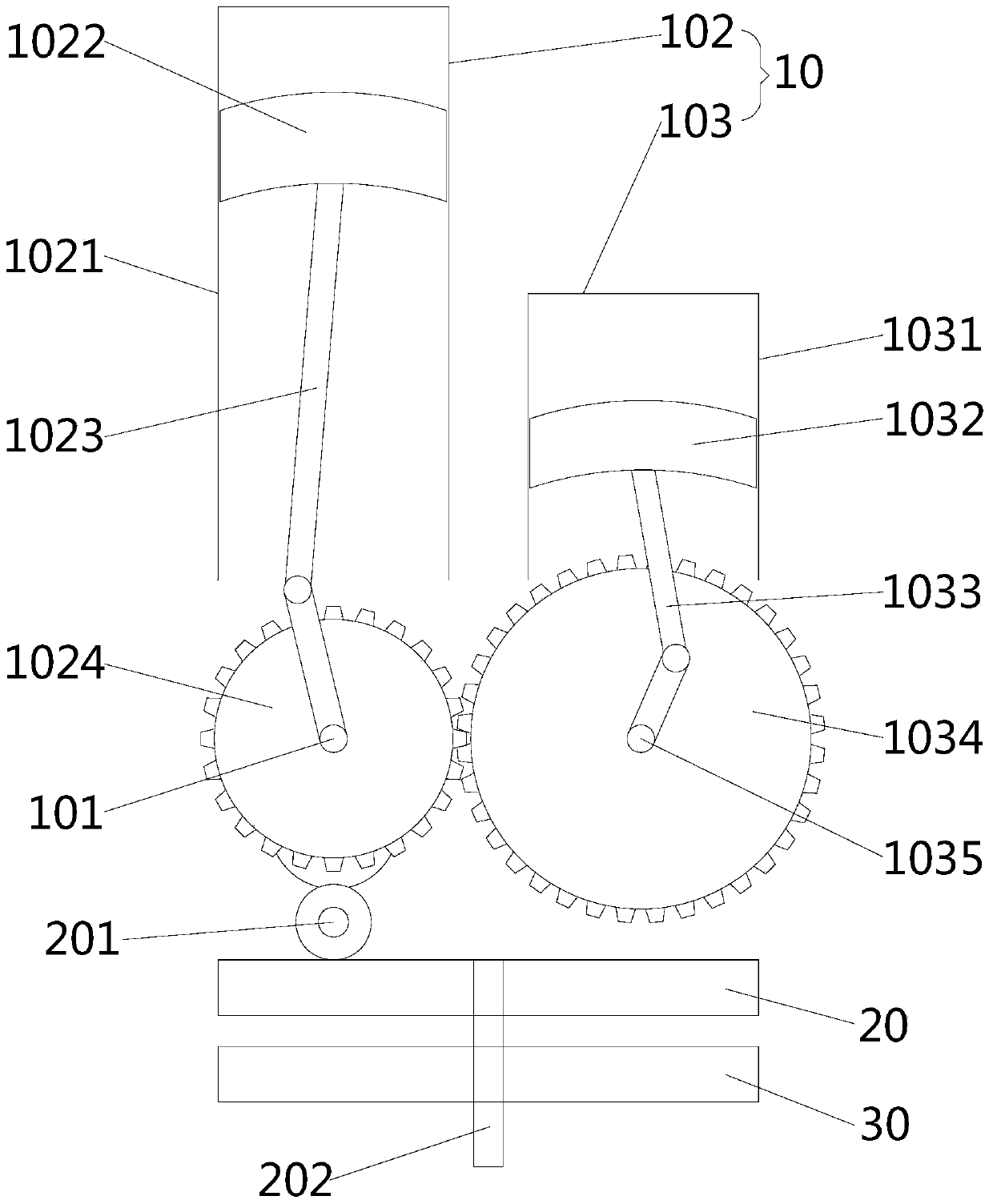

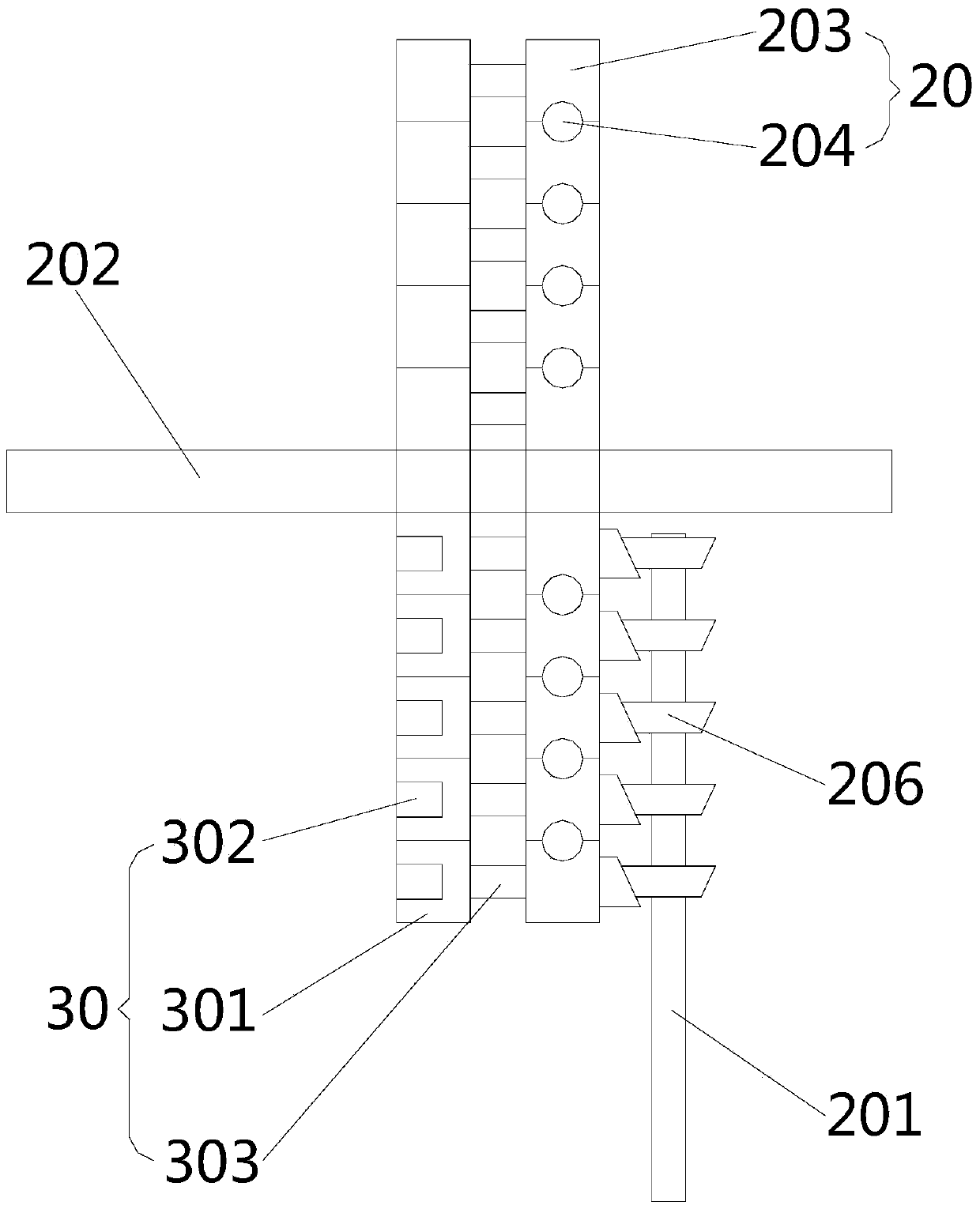

[0045] see figure 1 , this embodiment provides an integrated power assembly, which includes an afterburner engine 10 and a disc transmission 20, the afterburner engine 10 is provided with a main shaft 101, and the disc transmission 20 is provided with an input shaft 201 and The output shaft 202 is connected with the main shaft 101 and the input shaft 201 . The input shaft 201 can be connected with the driving wheel through a transmission structure.

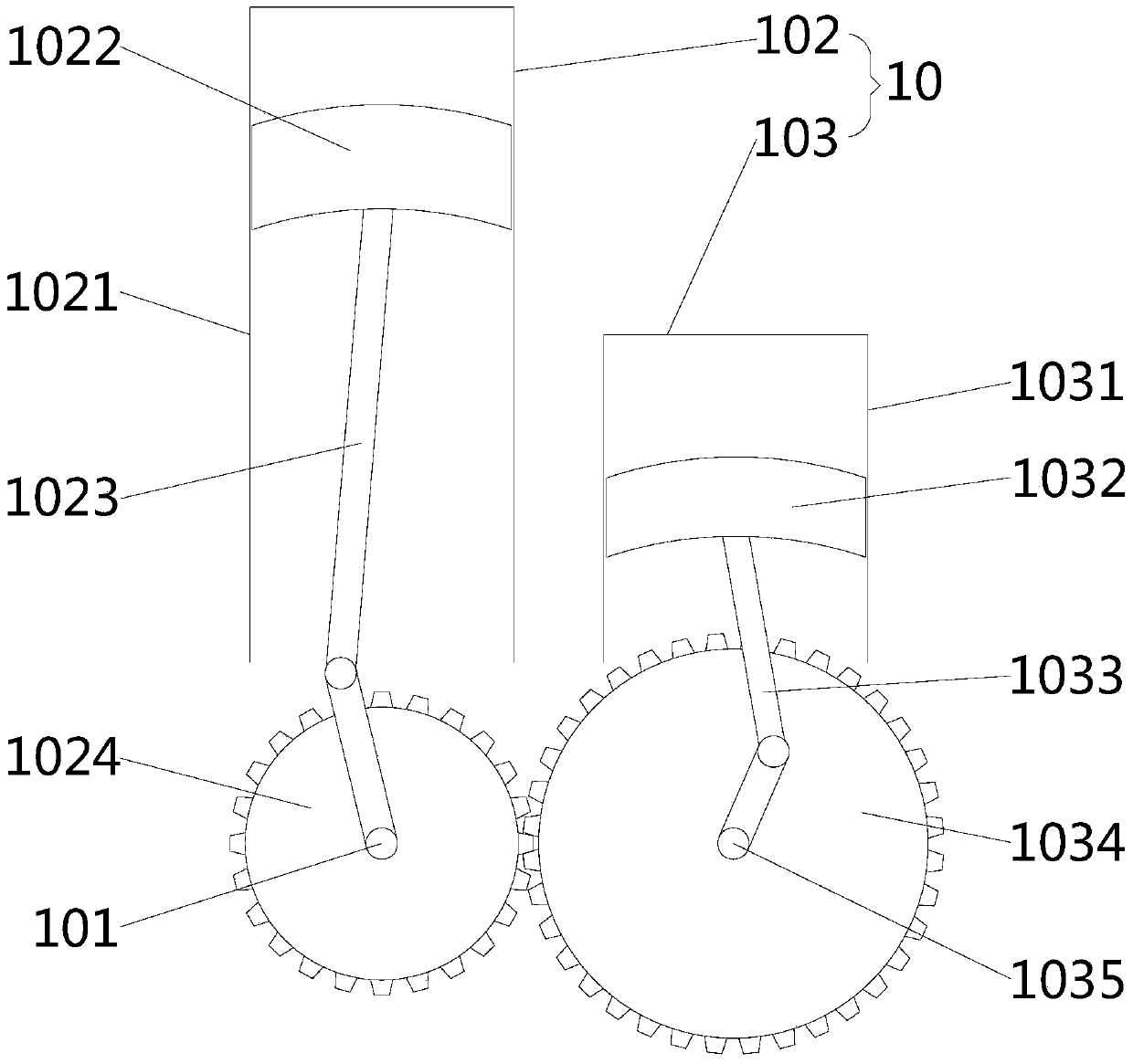

[0046] Among them, see figure 1 and figure 2 , the booster engine 10 includes a master cylinder 102 and a booster cylinder 103 , the master cylinder 102 is connected to the booster cylinder 103 , and the main shaft 101 is arranged on the master cylinder 102 . The booster engine 10 is formed by a master cylinder 102 and a booster cylinder 103. The stroke of the master cylinder 102 is greater than that of the booster cylinder 103. The master cylinder 102 and the booster cylinder 103 work together to achieve high power and fuel-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com