Pump body assembly of compressor

A technology for compressor pumps and components, applied to pump components, pumps, mechanical equipment, etc., can solve the problems of reduced cooling capacity of compressors, air entanglement, and poor fit between spring slides and rollers, and improve reliability. , to avoid the effect of cross gas and improve operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

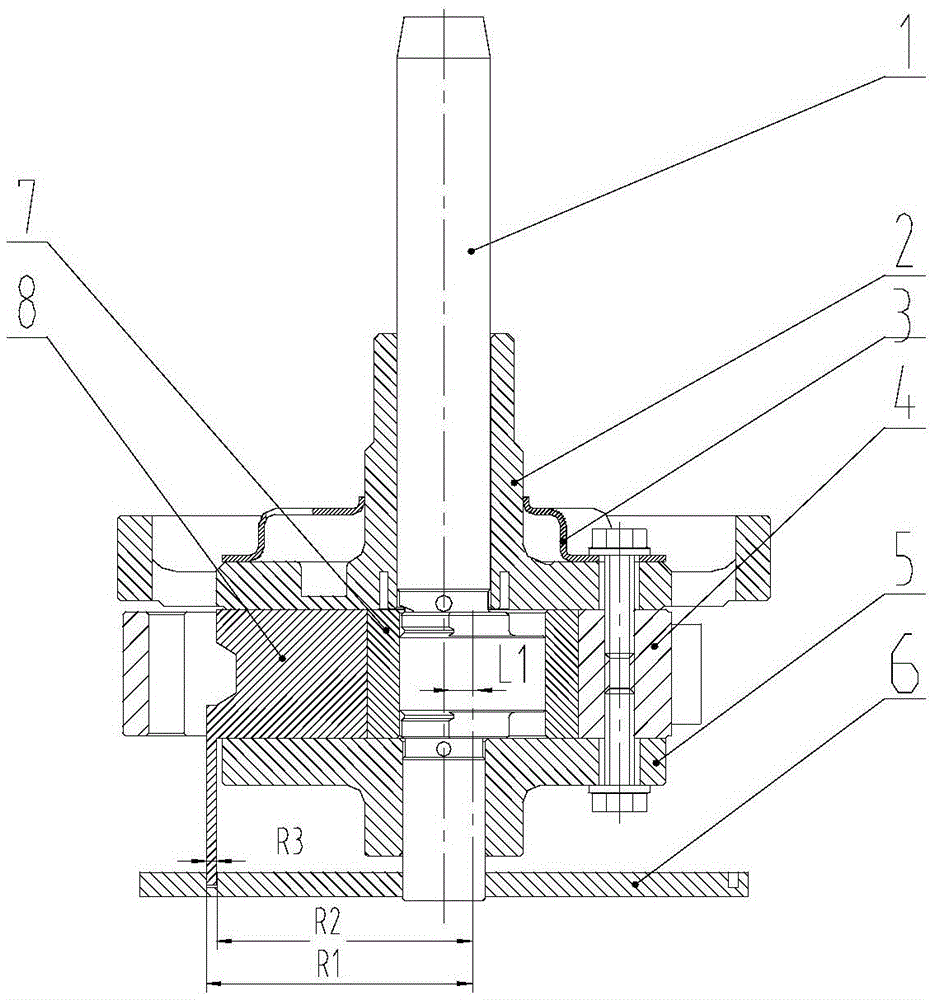

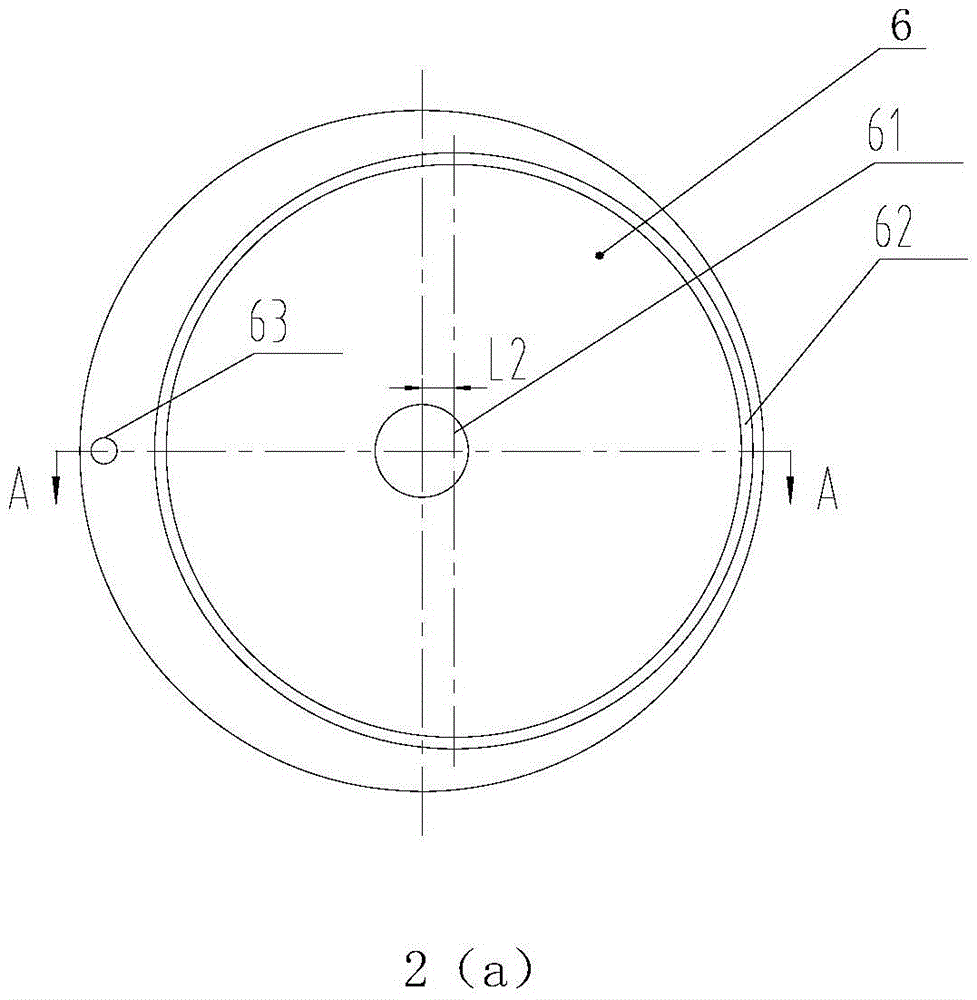

[0028] Such as Figure 1-5 As shown, the present invention provides a compressor pump body assembly, including a crankshaft 1, a cylinder 4, an upper flange 2, a lower flange 5, a roller 7 and a sliding vane 8, and it also includes a (located below the lower flange 5 and sleeved on the tail of the short shaft of the crankshaft 1) and a sheave structure 6 that rotates with the crankshaft 1, the sheave structure 6 corresponds to the sliding plate 8 is provided with a guide groove 62, and the sliding piece 8 protruding from the cylinder along the axial direction of the crankshaft 1 is provided with a device inserted into the guide groove 62 and driven by the guide groove 62 to make the slide piece 8. A guide rod 81 that reciprocates in the cylinder 4.

[0029] By adding a sheave structure at the lower end of the crankshaft, the sheave structure can be rotated together with the crankshaft, and a guide groove is set on it, a guide rod is set on the slide plate and the guide rod is...

Embodiment approach 2

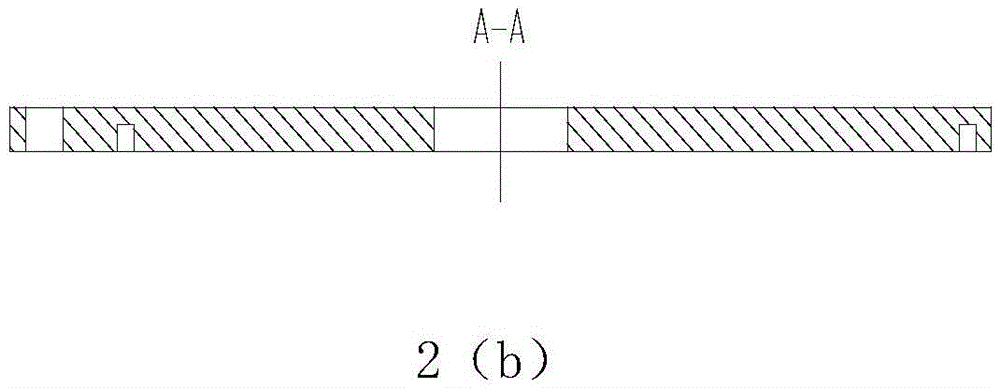

[0040] Such as Figure 6-7 As shown, this embodiment is a corresponding modification made on the basis of Embodiment 1, and the difference from Embodiment 1 is only that the sheave structure 6 is a circular stepped structure whose center protrudes downward. This can effectively ensure that the bending moment of the sliding vane guide rod is small and ensure its reliability, which is an optimized design of the sheave structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com