Thin-wall spoke type large gear

A spoke-type, large gear technology, which is applied in the direction of belts/chains/gears, components with teeth, portable lifting devices, etc., can solve problems such as difficult control of deformation size, hidden quality problems, and difficult processing, and achieve strength enhancement and improvement Effects of improved usability and deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

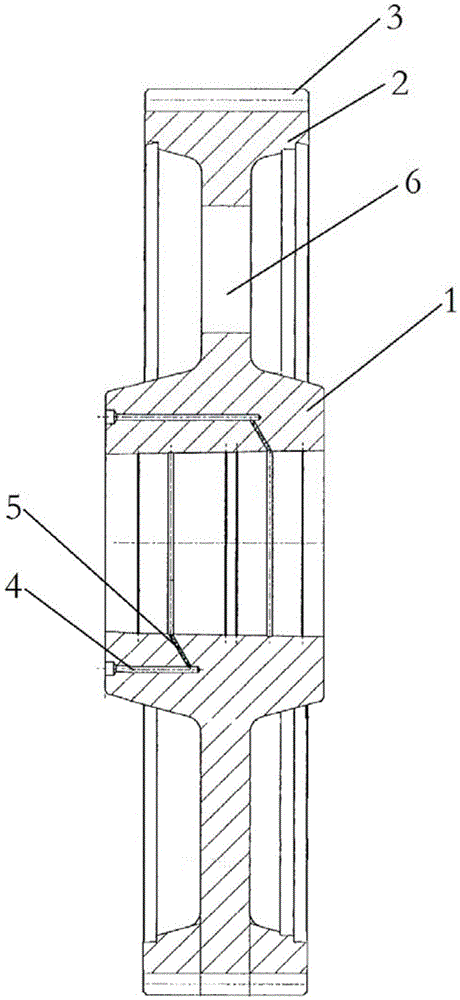

[0011] The present invention will be further described now in conjunction with accompanying drawing. These drawings are simplified schematic diagrams only to illustrate the basic structure of the present invention in a schematic way, so they only show the components relevant to the present invention.

[0012] Such as figure 1 As shown, a thin-walled spoke-type large gear has a wheel belly, and the wheel belly has a weight-reducing hole 6 formed after carburizing, and the wheel belly has a wheel belly inner ring 1, a wheel belly outer ring 2, a wheel belly The belly wall, the inner ring of the wheel belly 1 has a shaft hole for installing a gear shaft, the outer ring of the wheel belly 2 has a gear 3, and the wall of the wheel belly is between the adjacent weight-reducing holes 6, and the inner ring of the wheel belly 1 With lifting screw hole 4.

[0013] The inner ring 1 of the belly, the outer ring 2 of the belly, the wall of the wheel belly and the gear 3 are carburized, q...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap