Material Transfer Valve with Seat Protector

A material conveying valve, protective sleeve technology, applied in valve details, valve device, sliding valve and other directions, can solve the problems of difficult processing, short service life, leakage, etc., to improve service life and sealing performance, easy to manufacture, simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

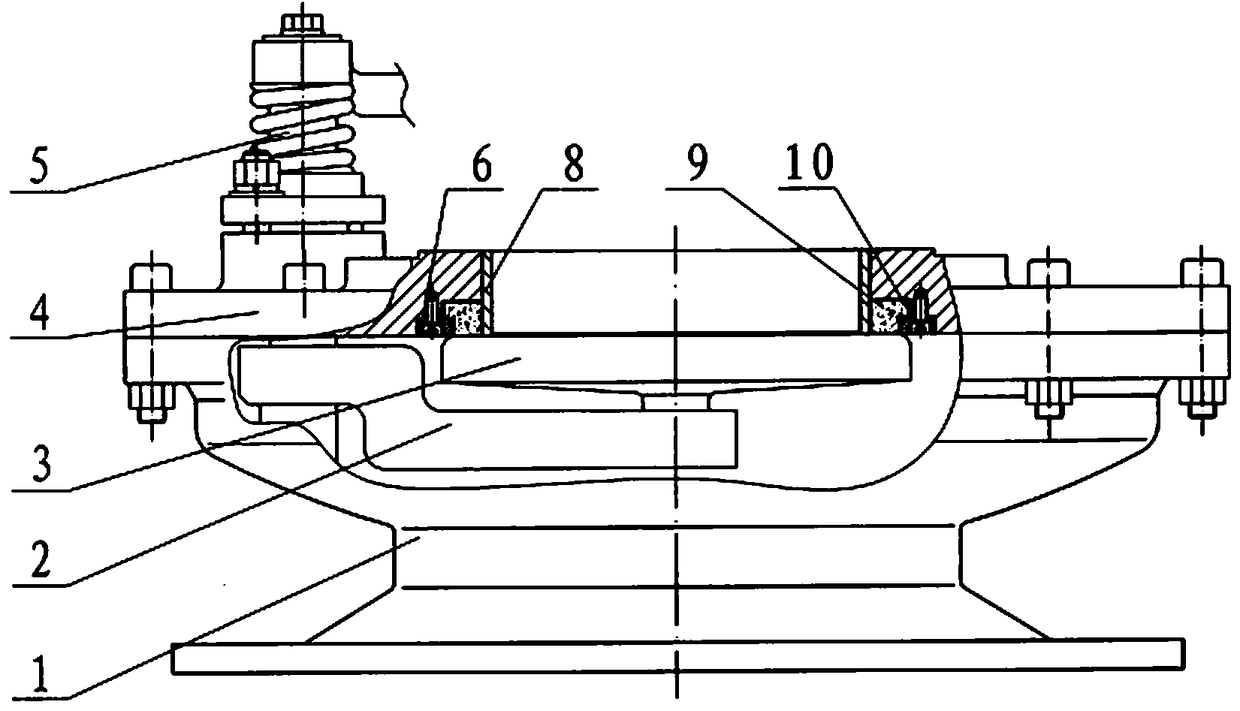

Embodiment 1

[0014] The material delivery valve with a protective sleeve on the valve seat, the valve body 1 and the valve cover 4 are connected by bolts, the lower end of the rotating shaft 5 is fixedly connected with one end of the rotating arm 2, the other end of the rotating arm is connected with the valve plate 3, and the valve plate and the valve cover The ceramic valve seat 9 on 4 is sealed and fit. The central hole of the valve cover 4 is a straight hole, and its lower end surface has an annular groove. The ceramic valve seat 9 is an L-shaped ring with a wide upper part and a narrower lower part. The groove is statically matched with the ceramic valve seat 9, the lower end surface of the valve cover, the lower end surface of the ceramic valve seat, and the lower end surface of the metal pressure ring 6 are on the same plane, the ceramic valve seat and the annular groove are of the same height, the lower part of the annular groove, the ceramic valve seat 9, the height of the metal pr...

Embodiment 2

[0016] The upper end of the central hole of the valve cover 4 has a step to cooperate with the upper end flange of the steel sleeve 8, which is convenient for the installation, disassembly and positioning of the steel sleeve 8. All the other are identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com