Headrest greasing machine

An oiler and headrest technology, applied in mechanical equipment, engine components, engine lubrication, etc., can solve the problems of laborious insertion and removal, unable to guarantee the pulling force of products with oil consumption, easy to pollute the seat, etc., and achieve constant consumption. , Save labor hours, reduce the effect of oil mist leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

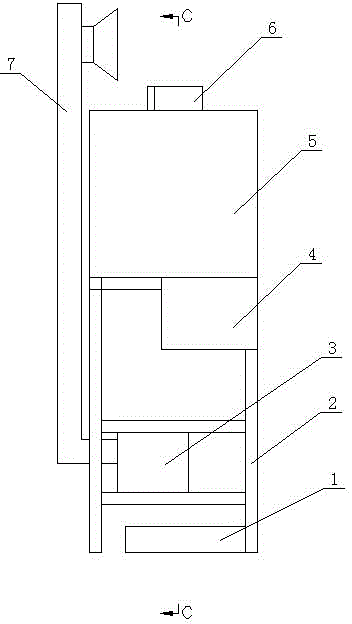

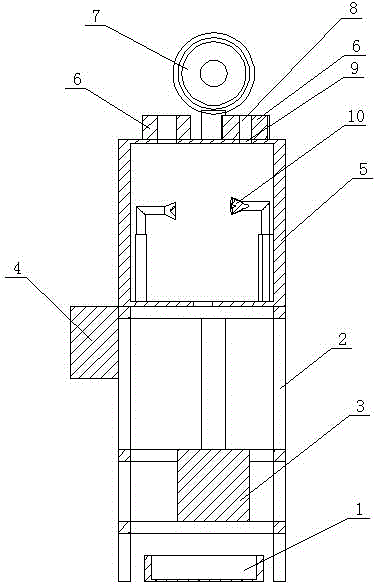

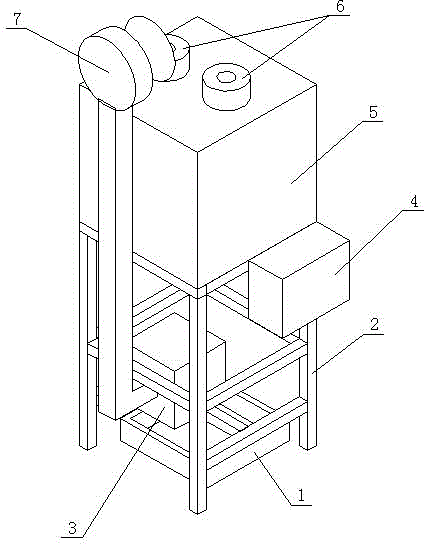

[0011] Such as figure 1 As shown in -3, it is a headrest oiler, including a frame 2, which is connected with an oil pump 3 and a fuel injection tank 5, and the oil pump 3 is set under the fuel injection tank 5, and an oil collecting pan is set under the oil pump 3 1. The fuel injection box 5 is connected with two fuel injectors 10, and the two fuel injectors 10 are connected with the same electromagnetic valve 4 through the oil pipe, and the electromagnetic valve 4 is connected with the oil pump 3 through the oil pipe. Two sockets 9 are arranged on the fuel injection box 5, each socket 9 is respectively arranged above the corresponding positions of the fuel injection nozzles 10, and the headrest guide rods are respectively connected to the fuel injection box 5 at each socket 9 Socket 6, each headrest guide rod socket 6 is respectively provided with a central hole 8, and the central hole 8 of each headrest guide rod socket 6 is coaxially arranged with the corresponding socket ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com