Optical element thermal stress assessment system in vacuum environment

A technology of optical components and vacuum environment, which is applied in the fields of optical devices, optical radiation measurement, scientific instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

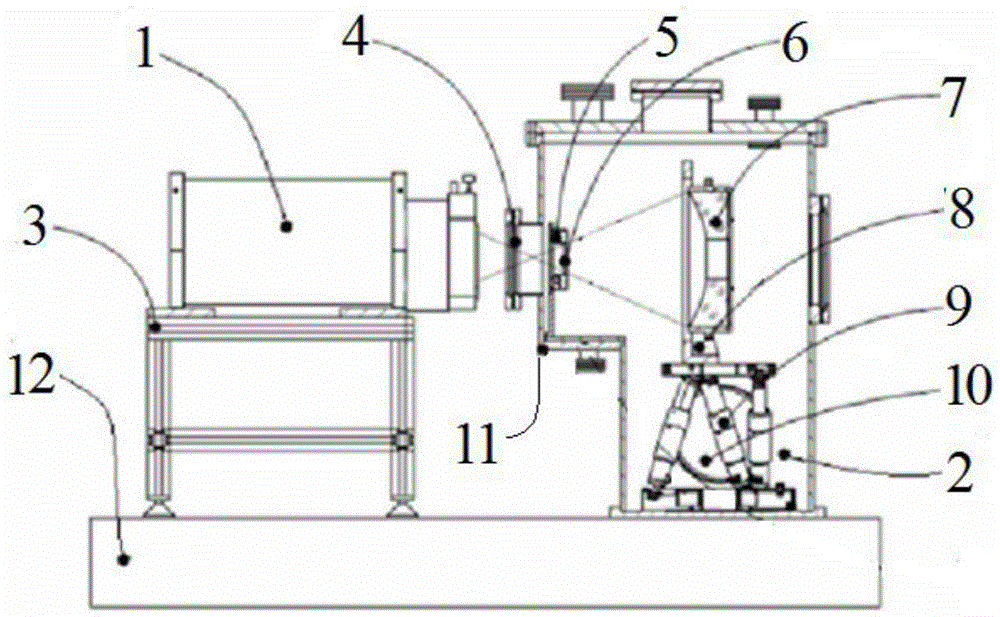

[0018] Such as figure 1 As shown, a thermal stress evaluation system for optical components in a vacuum environment, which includes an interferometer 1, a vacuum tank 2, a support frame 3, a glass window 4, a quartz heating tube 5, a quartz heating tube fixing seat 6, an optical component 7. Support structure 8, six degrees of freedom adjustment platform 9 and steps 11.

[0019] The interferometer 1 is placed on the support frame 3, and the support frame 3 is a five-degree-of-freedom adjustment mechanism, which can realize the adjustment of the five-degree-of-freedom of the interferometer 1 except rotation.

[0020] The support frame 3 and the vacuum tank 2 are placed on an optical platform 12 with a vibration isolation effect. The upper part of the vacuum tank 2 is provided with a step 11, the glass window 4 is arranged on the outer surface of the step 11, the quartz heating tube 5 is fixed on the quartz heating tube fixing seat 6, the quartz heating tube fixing seat 6 is ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com