Torsion calibration device

A calibration device and torsion technology, which is applied in the direction of measuring devices, force/torque/power measuring instrument calibration/testing, instruments, etc., can solve the problems of difficult debugging, unsatisfactory use occasions, high installation accuracy requirements, etc., to achieve installation and debugging Convenience, long service life and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

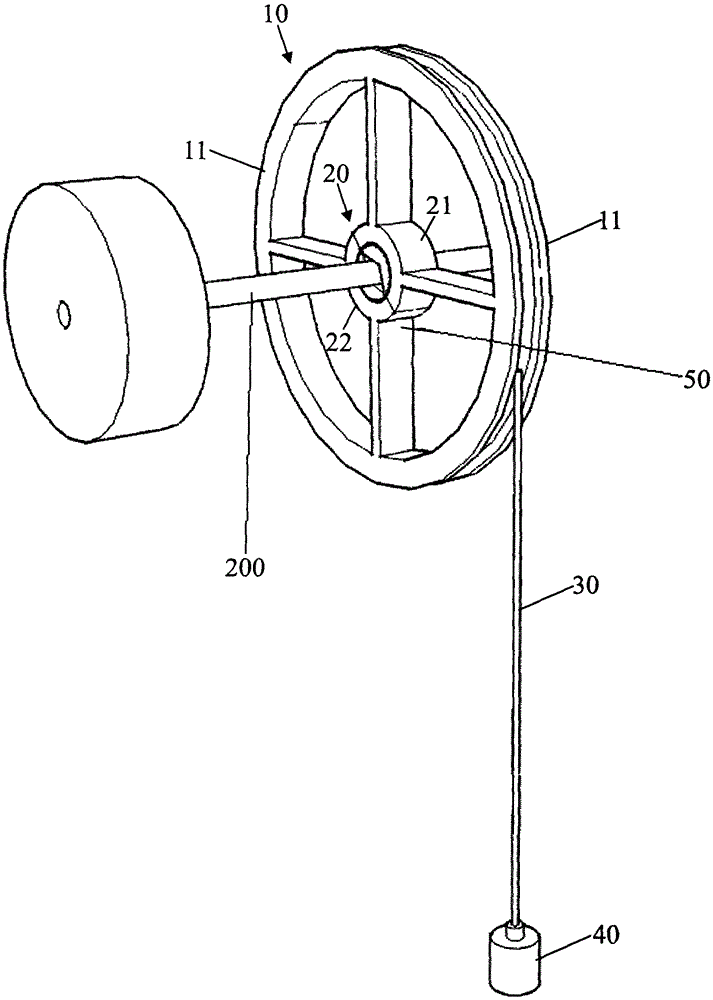

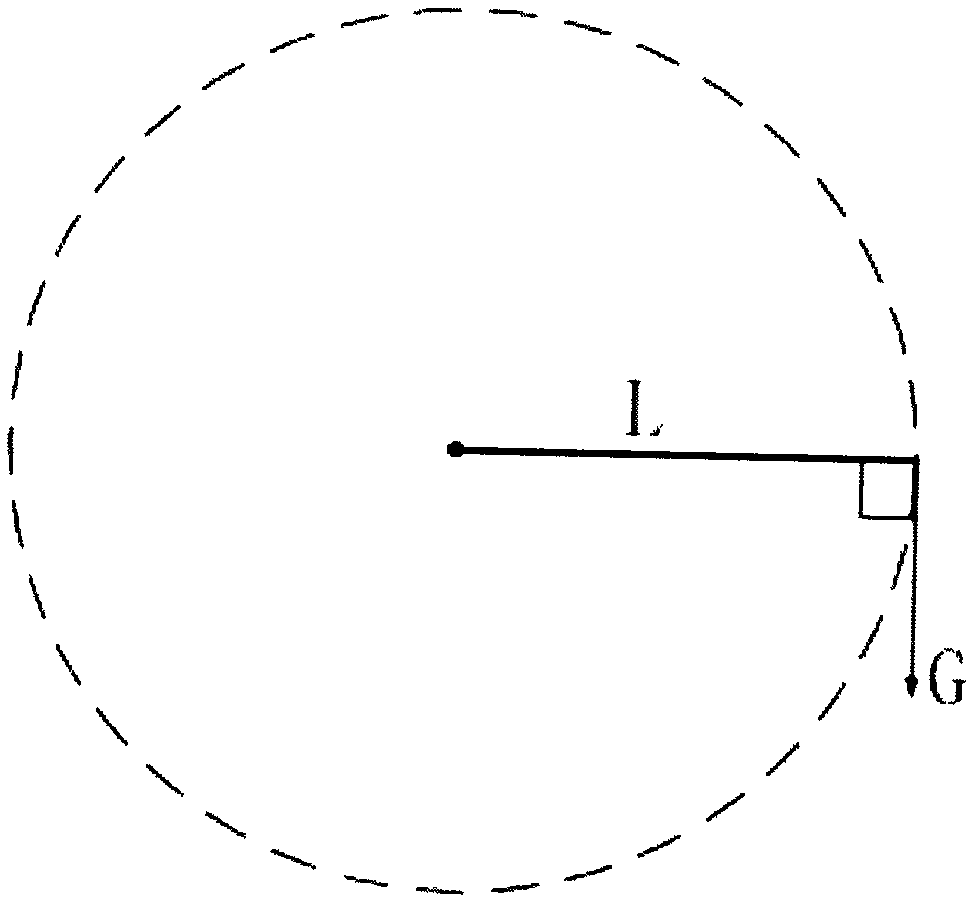

[0024] The torque calibrating disk 10 forms a balanced disc moment arm, and the torsion calibrating disk 10 includes two semi-disc structural members 11, and the ends of the two semi-disc structural members 11 are fixedly connected. As an embodiment, the semi-disc structure 11 is a semi-circular structure, so that two semi-circular structure semi-disc structures 11 are connected to form a circular torsion calibration disc.

[0025] The shaft locking mechanism 20 is used to fix the torque calibration device of the present invention to the shaft 200 of the system under test, and transmit the torque of the torque calibration disk 10 to the shaft under test. The shaft locking mechanism 20 can be A cylindrical structure, the cylindrical shaft locking mechanism 20 is arranged coaxially with the torque calibrating disk 10 .

[0026] Further, the shaft locking mechanism 20 has a locking position, and the locking position is located at the center of the circle of the torque calibration...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com