Aluminum sheet substrate for coating shearing strength test and test sample thereof

A shear strength, aluminum sheet substrate technology, applied in the field of aluminum sheet substrates and test samples, can solve the problems of inaccurate test data, large data fluctuations, invalid results, etc., and solve the problems of inaccurate and difficult test data. Deformation, the effect of improving convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The embodiments will be described in detail below in conjunction with the accompanying drawings.

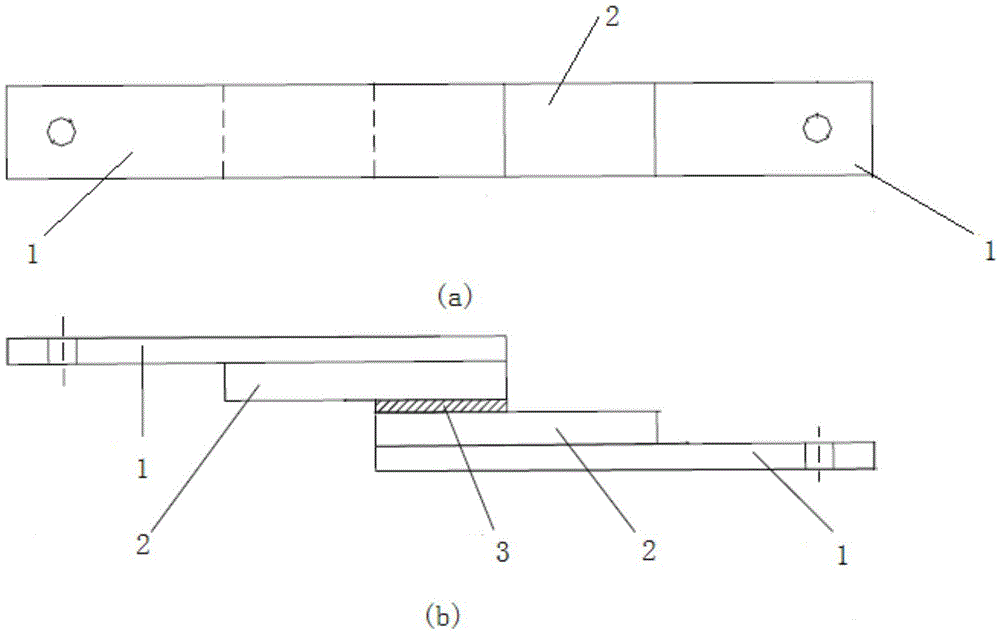

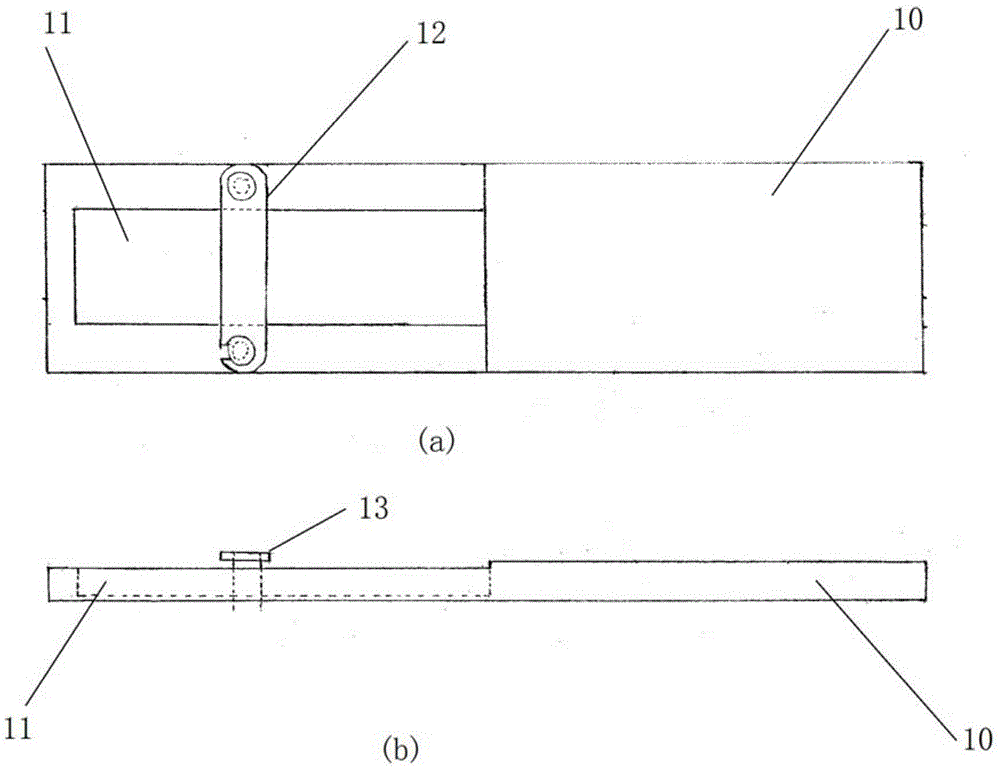

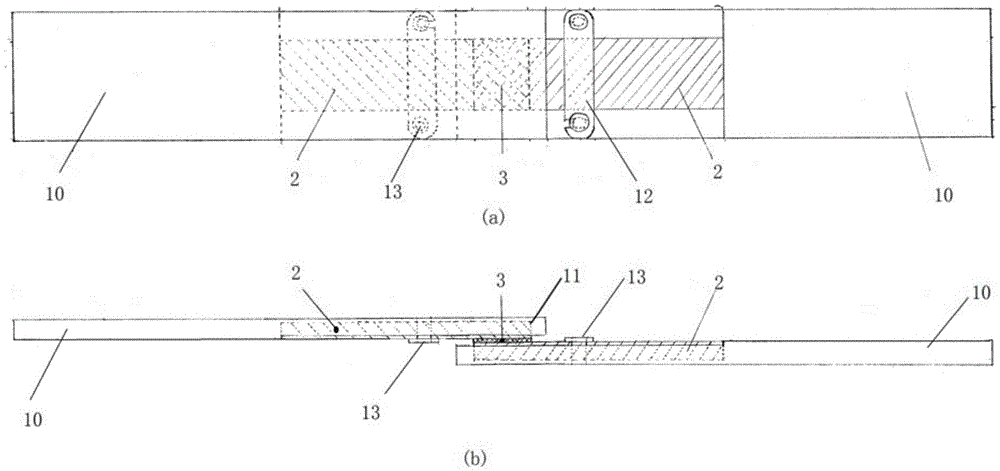

[0016] Such as figure 2 a and figure 2 As shown in b, the aluminum sheet substrate 10 used for the coating shear strength test of the present invention includes a slot 11 for inlaying a glass plate or a porcelain plate arranged on one side of the aluminum sheet substrate and is used for placing glass in the slot. plate or ceramic plate and then clamp one or more movable buckles of the glass plate or porcelain plate, the movable buckle includes a pivotable movable clamping piece 12 fixed on one side of the slot and fixed on the slot. On the other side of the fixed buckle 13, the movable clamping piece is provided with a clamping groove that can cooperate with the fixed buckle. The figure shows that the clamping groove of the movable clamping piece cooperates with the fixed buckle and is in a clamped state.

[0017] Preferably, the thickness of the side of the aluminum ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com