Square adhesive structure and manufacturing method thereof

A production method and technology of digital glue, applied in nonlinear optics, instruments, optics, etc., can solve the problems of high cost of digital glue, low cutting utilization rate of black and white glue, etc., to ensure optical taste, high utilization rate, The effect of cutting convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

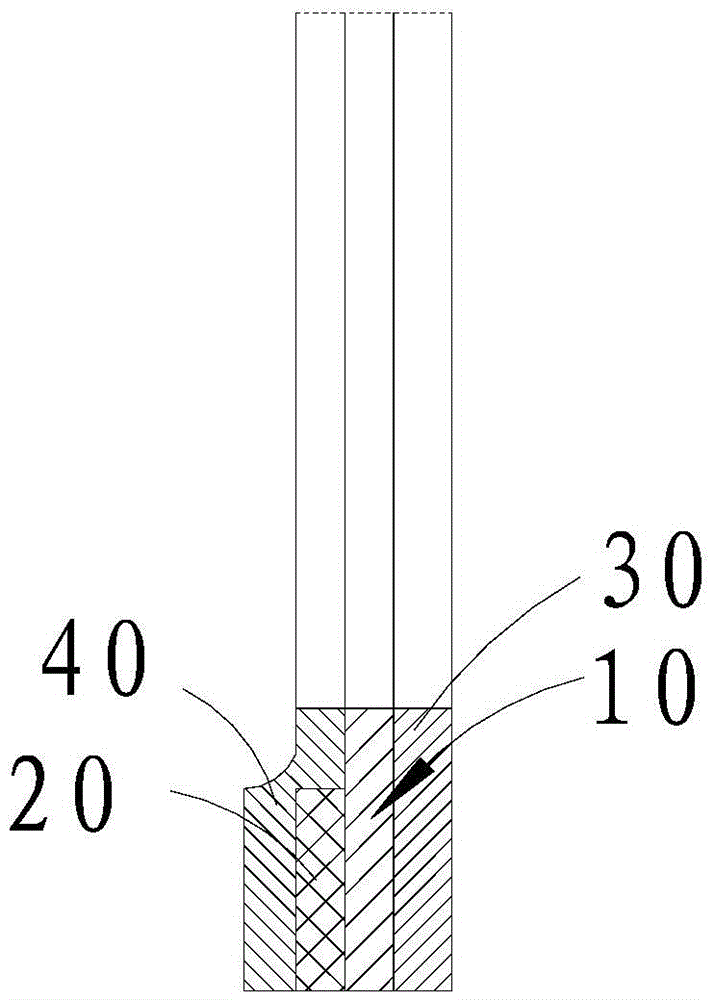

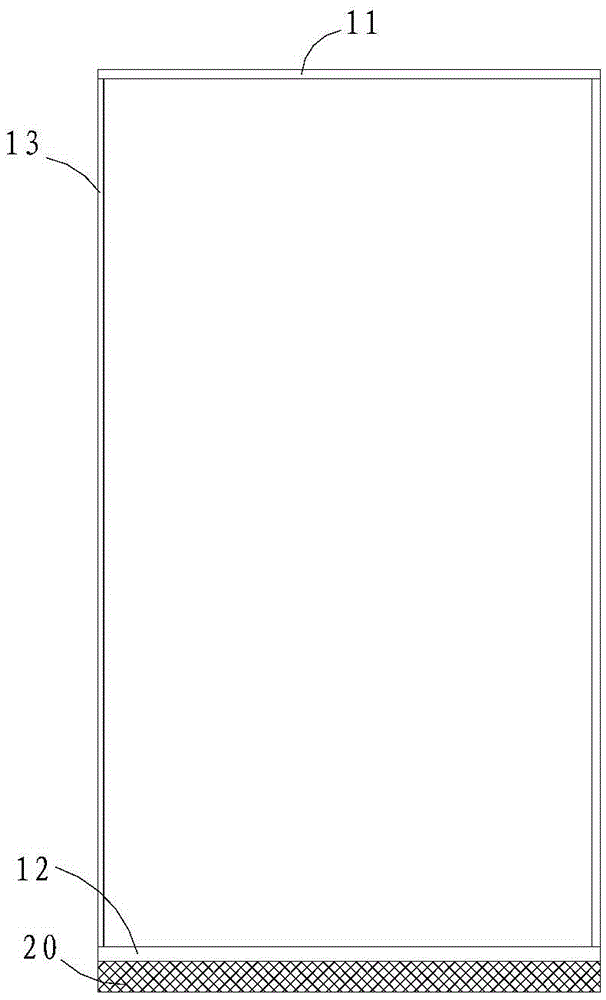

[0034] refer to Figure 1~3 , the word-of-mouth glue structure of the present embodiment comprises black and white glue 10, heavy industry glue 20, first protective film 30 and second protective film 40, and black and white glue 10 comprises the upper rubber strip 11, lower rubber strip 12 and The side rubber strips 13 on both sides, among the black and white glue 10, the lower rubber strip 12 is the widest; Narrow; the first protective film 30 is attached to the other side of the black and white adhesive 10 relative to the heavy industrial adhesive; the second protective film 40 is attached to the outer surface of the heavy industrial adhesive 20 and the black and white adhesive 10 at the same time.

[0035] Here, Heavy Industry Adhesive 20 is Heavy Industry Repair Tape, which can be used to assist in attaching or peeling off black and white adhesive, usually OCA (Optically Clear Adhesive), used to attach to the side of the glass panel, and black and white adhesive is used to...

Embodiment 2

[0038] Such as Figure 4 In order to avoid part of the black and white glue still adhering to the PET film when the first protective film 30 is torn off, in this embodiment, the side rubber strips 13 on both sides are preferably extended to the two sides of the inner side wall and the widest lower rubber strip 12 respectively. The lower rubber strip 12 is surrounded in the middle. Since the lower rubber strip 12 has a wider width, its adhesion is stronger and it is not easy to be lifted. In addition, it is preferable that the two ends of the heavy industrial glue 20 also extend to the joint. On the side rubber strips 13 on both sides.

[0039] In this way, when the first protective film 30 is peeled off from the corner, the side rubber strips 13 on both sides will protect the lower rubber strip 12 in the middle, and the side rubber strips 13 on both sides will be connected with the wider lower rubber strip 12 in the middle. Forming a whole reduces the probability of black and...

Embodiment 3

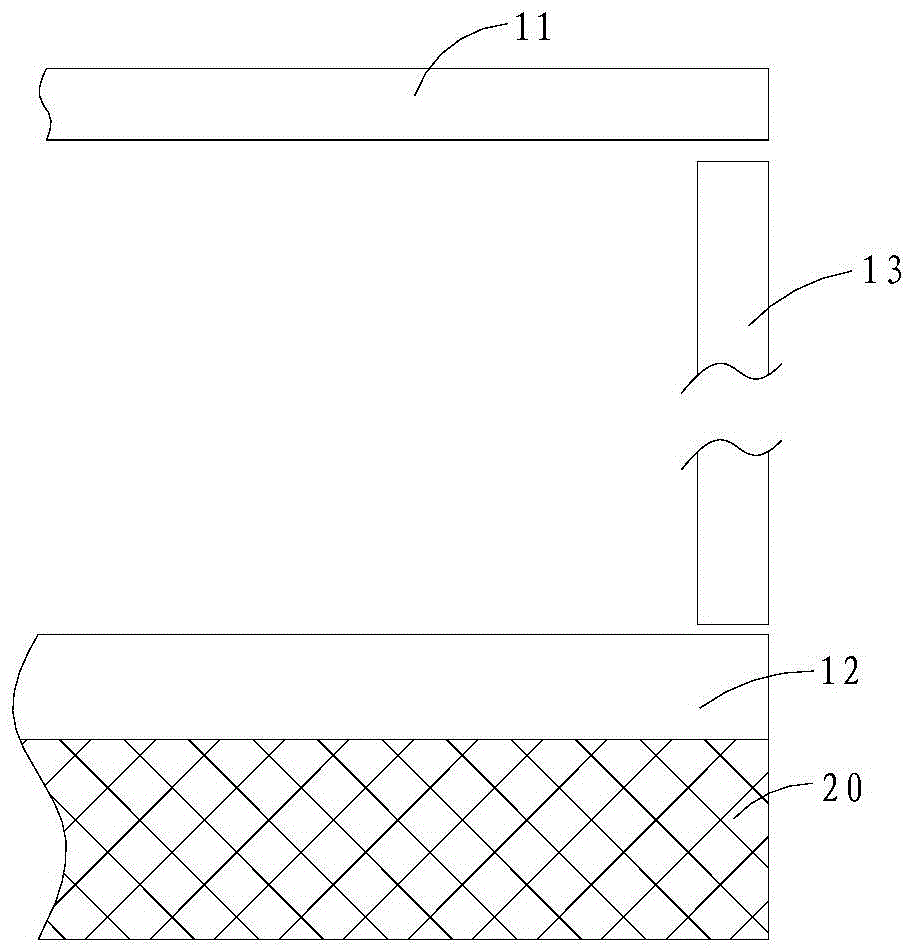

[0041] Such as Figure 5 As shown, the side rubber strips 13 on both sides extend to the inner side walls to respectively attach to the two ends of the lower rubber strip 12, and enclose the lower rubber strip 12 in the middle. Different from Embodiment 2, each side rubber strip 13 of this embodiment is in an "L" shape, including mutually perpendicular narrow strips 131 and wider wide strips 132, preferably the wide strips 132 have the same width as the lower rubber strips 12, and Splicing and co-linear with the lower rubber strip 12. In addition, the two ends of the heavy industrial glue 20 are extended to the side glue strips 13 attached on both sides. In this way, the tearing force (F in the figure) exerted from the corner of the "L"-shaped side rubber strip 13 is more difficult to peel off the narrow strip 131 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com