An intelligent control method for main steam pressure of supercritical or ultra-supercritical unit boiler

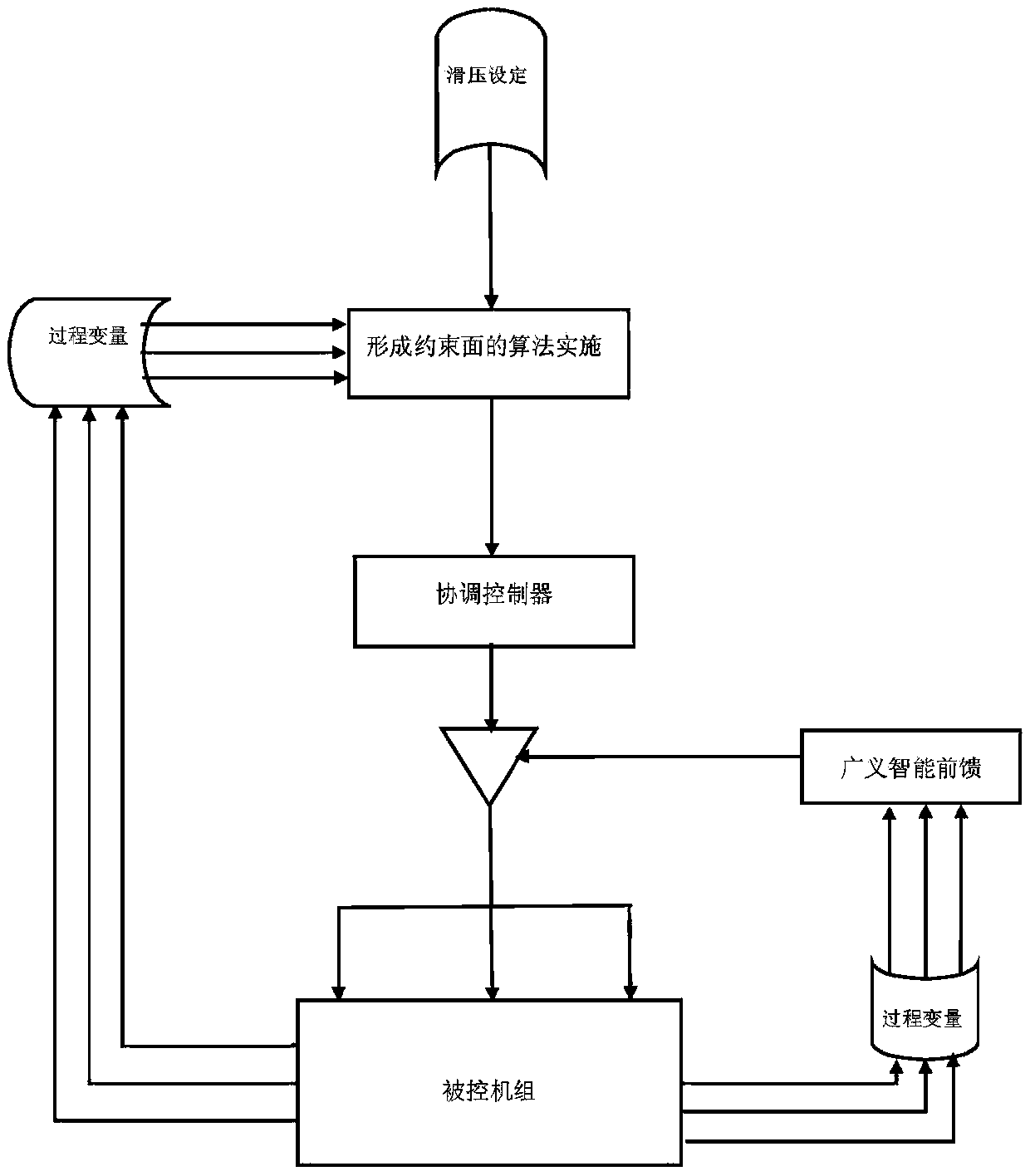

A technology of ultra-supercritical unit and main steam pressure, applied in the direction of adaptive control, general control system, control/regulation system, etc., can solve problems such as disturbance and poor anti-disturbance ability, and achieve improved stability, robustness, and safety Sexual and economical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

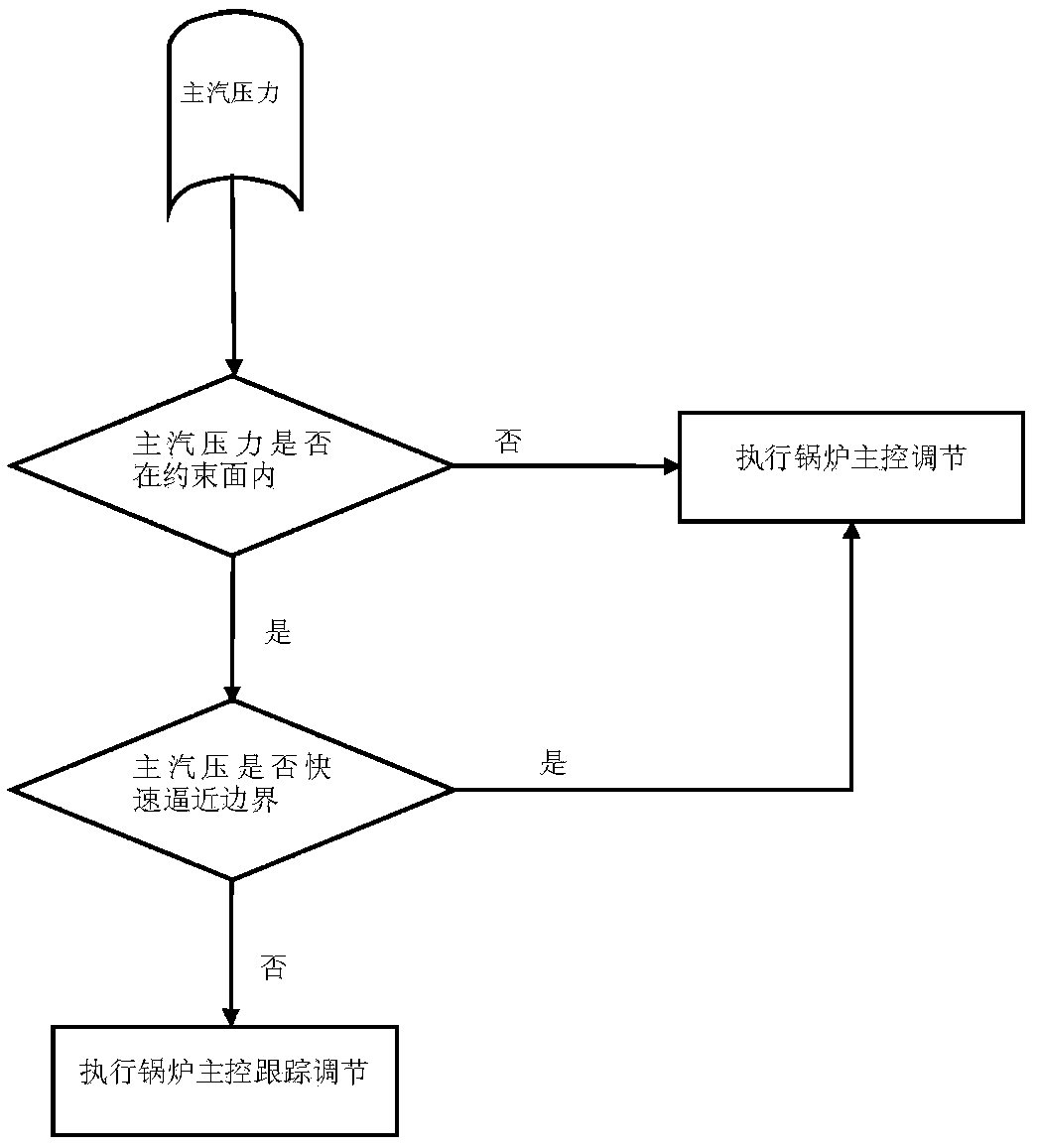

[0016] In the intelligent control method of the main steam pressure of supercritical or ultra-supercritical unit boilers, the main controller of the boiler will automatically adjust the initial Impulse", "Brake Impulse" and "Dynamic Compensation Coal Feed" magnitude and direction, as well as the main steam pressure setting value and its PID adjustment, where the main steam pressure setting value is based on the preset sliding pressure curve Obtained, the sliding pressure curve is determined by the operation mode and thermal characteristics of the steam turbine in the super (super) critical thermal power unit. Different units have different sliding tooth curves, which refers to the relationship between the load and the pressure setting value during the operation of the unit (how much load corresponds to how much pressure).

[0017] As shown in the table below:

[0018] x (Load %): 0 40 45.45 60.6 69.69 78.78 100 110

[0019] y (design pressure MPa): 4.2 10.4 11.2 13.4 14.8 16...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com