High precision constant temperature control device and method

A constant temperature control, high-precision technology, applied in non-electric variable control, control/regulation systems, simultaneous control of multiple variables, etc., can solve problems such as high prices and achieve the effect of suppressing the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

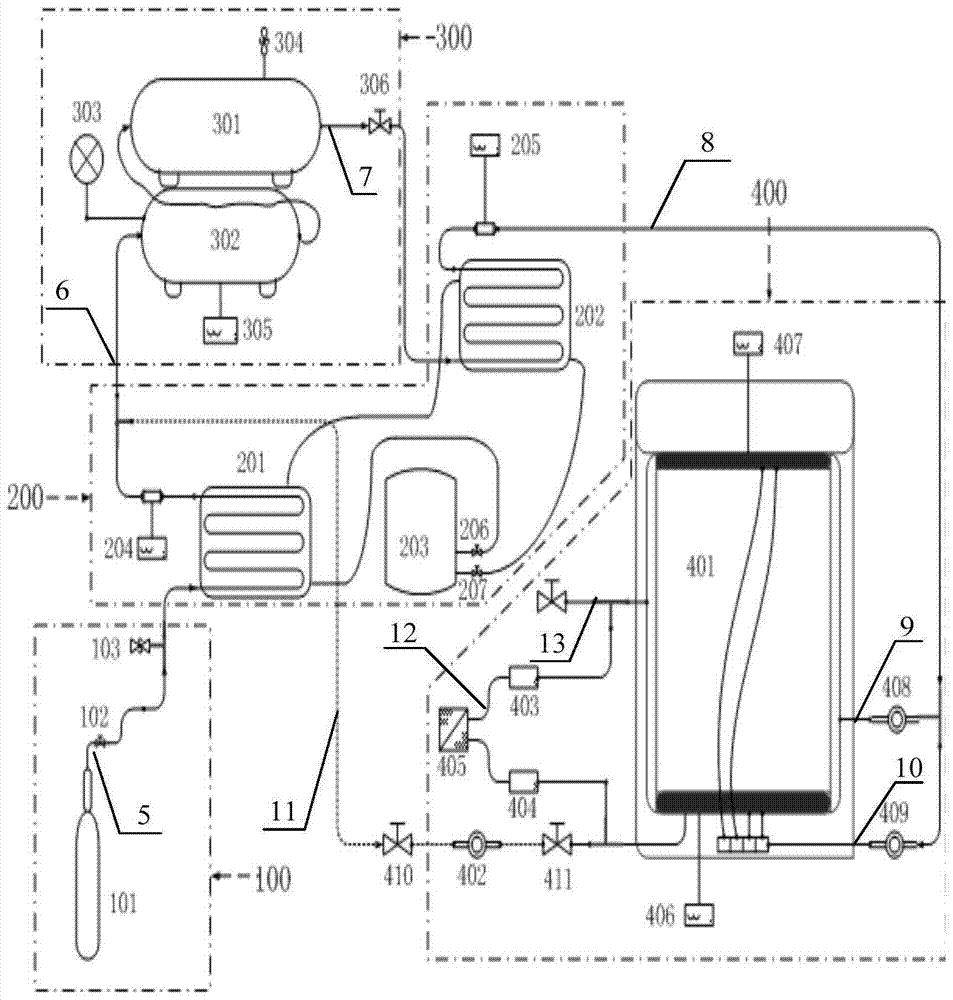

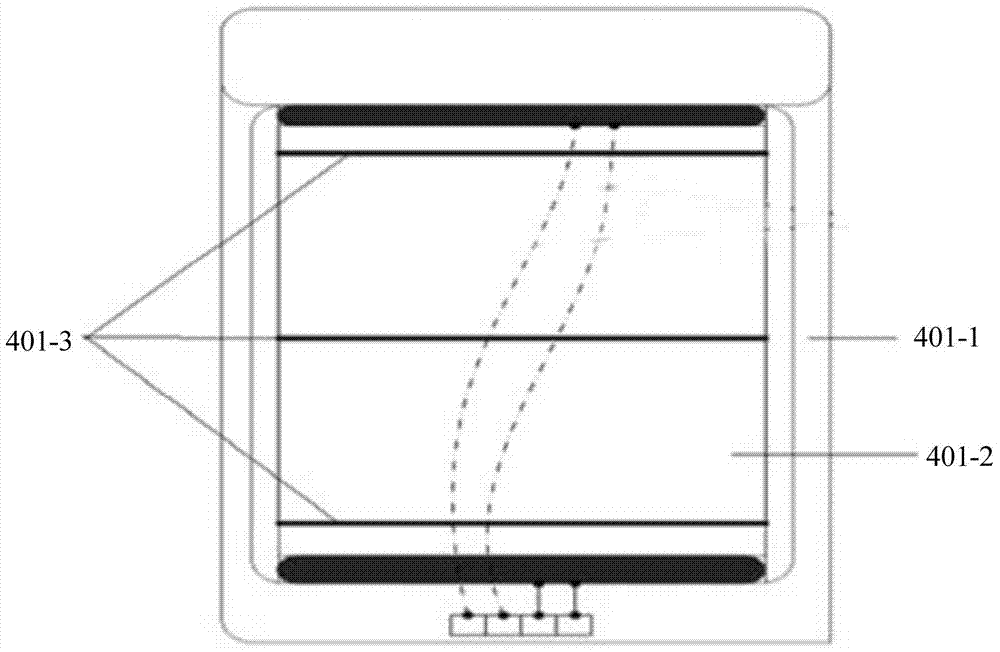

[0034] See attached figure 1, attached figure 2 And attached image 3 , the high-precision constant temperature control device of the present invention includes a gas source module 100, a heat exchange module 200, a gas storage module 300 and a control module 400; The modules 300 are in communication, and the control module 400 is in communication with the heat exchange module 200 through pipes.

[0035] The air source module 100 includes an air source 101, an air source valve 102, and an air source safety valve 103; the air source 101 communicates with the heat exchange module 200 through a pipeline I, and the pipeline I is sequentially provided with an air source valve 102 and an air source safety valve 103. Valve 103.

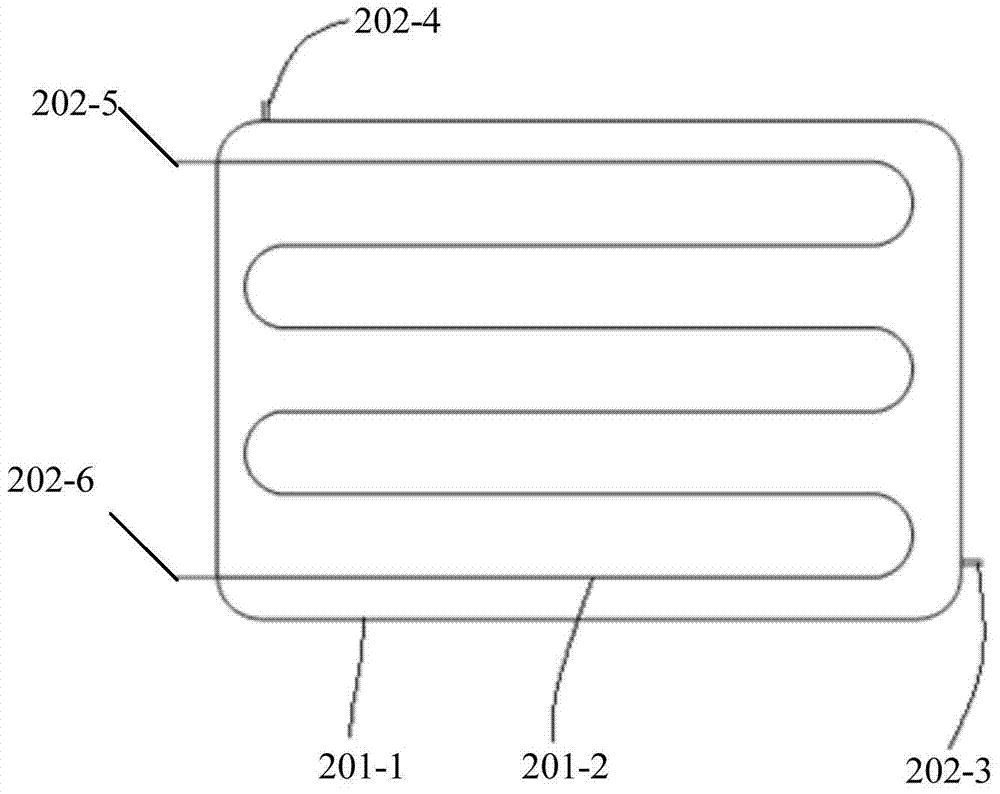

[0036] The heat exchange module 200 includes a primary heat exchanger 201, a thermometer I 204, a secondary heat exchanger 202, a thermometer II 205, and a constant temperature water bath device 203; the primary heat exchanger 201 has the same structure ...

specific Embodiment 2

[0055] The difference between this embodiment and the first embodiment is that the heat exchange medium in step one is water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com