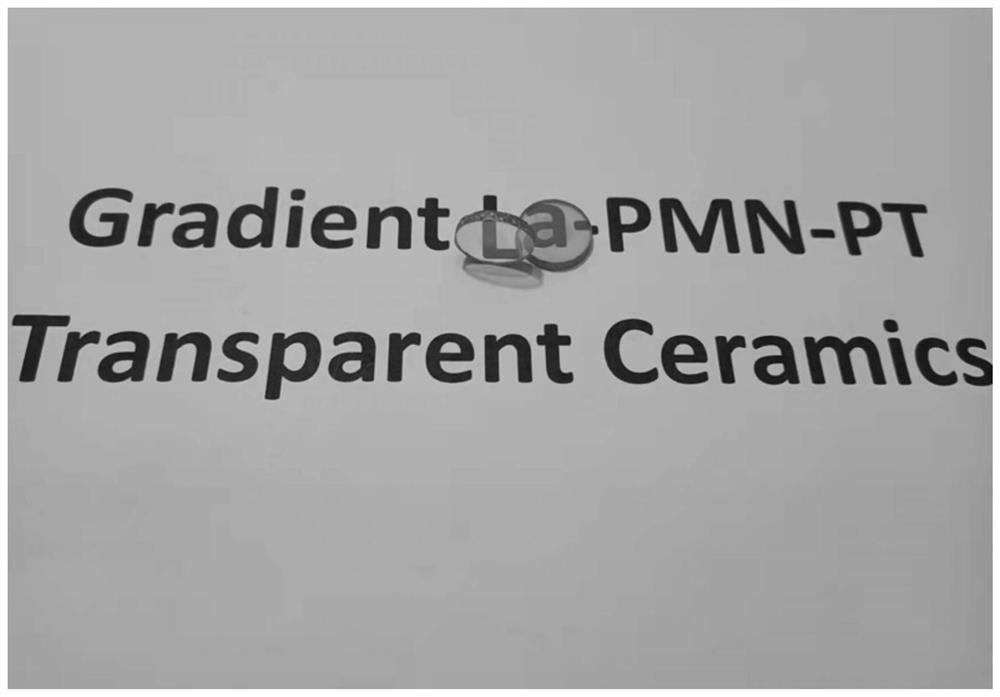

Transparent electro-optical ceramic material with high electro-optical coefficient and high temperature stability and preparation method thereof

A technology of electro-optic coefficient and electro-optic ceramics, which is applied in the field of transparent electro-optic ceramic materials with high electro-optic coefficient and high temperature stability and its preparation, can solve the problems of poor temperature stability of electro-optic coefficient, and achieve temperature stability, simple operation, and wide The effect of applying the foreground

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The present embodiment provides a method for preparing a transparent electro-optic ceramic material with high electro-optic coefficient and high temperature stability, comprising the following steps:

[0041] a) According to MgNb 2 O 6 General formula for accurate weighing of stoichiometric ratios of MgO and Nb 2 O 5 , using deionized water as the medium, planetary ball milling for 6 hours, calcined at 1100 °C for 4 hours, and using deionized water as the medium again, planetary ball milling for 6 hours to obtain MgNb 2 O 6 ceramic powder;

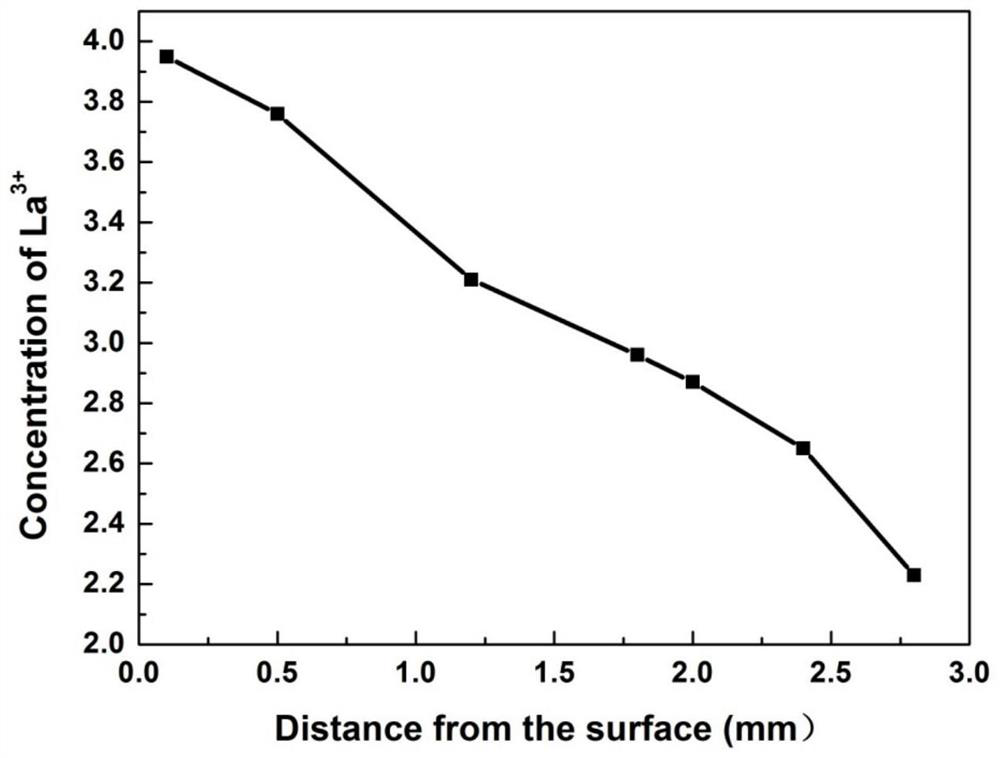

[0042] b) According to (Pb 1-x Ln x )[(Mg 1 / 3 Nb 2 / 3 ) y Ti 1-y ] 1-x / 4 O 3 The general formula, wherein the rare earth element Ln is La, y=0.75, the doping content of the rare earth element La is x=0.02, 0.03, 0.04, respectively, and the stoichiometric ratios of PbO and TiO are accurately weighed 2 , La 2 O 3 Add the MgNb obtained in step a) 2 O 6 In the ceramic powder, deionized water was used as the medium, plane...

Embodiment 2

[0050] The present embodiment provides a method for preparing a transparent electro-optic ceramic material with high electro-optic coefficient and high temperature stability, comprising the following steps:

[0051] a) According to MgNb 2 O 6 General formula for accurate weighing of stoichiometric ratios of MgO and Nb 2 O 5 , using alcohol as the medium, planetary ball milling for 6 hours, calcined at 1100 ℃ for 4 hours, using alcohol as the medium again, planetary ball milling for 6 hours, to obtain MgNb 2 O 6 ceramic powder;

[0052] b) According to (Pb 1-x Ln x )[(Mg 1 / 3 Nb 2 / 3 ) y Ti 1-y ] 1-x / 4 O 3 The general formula, wherein the rare earth element Ln is La, y=0.80, the doping content of the rare earth element La is x=0.01, 0.02, 0.03, respectively, and the stoichiometric ratios of PbO and TiO are accurately weighed 2 , La 2 O 3 Add the MgNb obtained in step a) 2 O 6 In the ceramic powder, using alcohol as the medium, planetary ball milling for 6 hours, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com