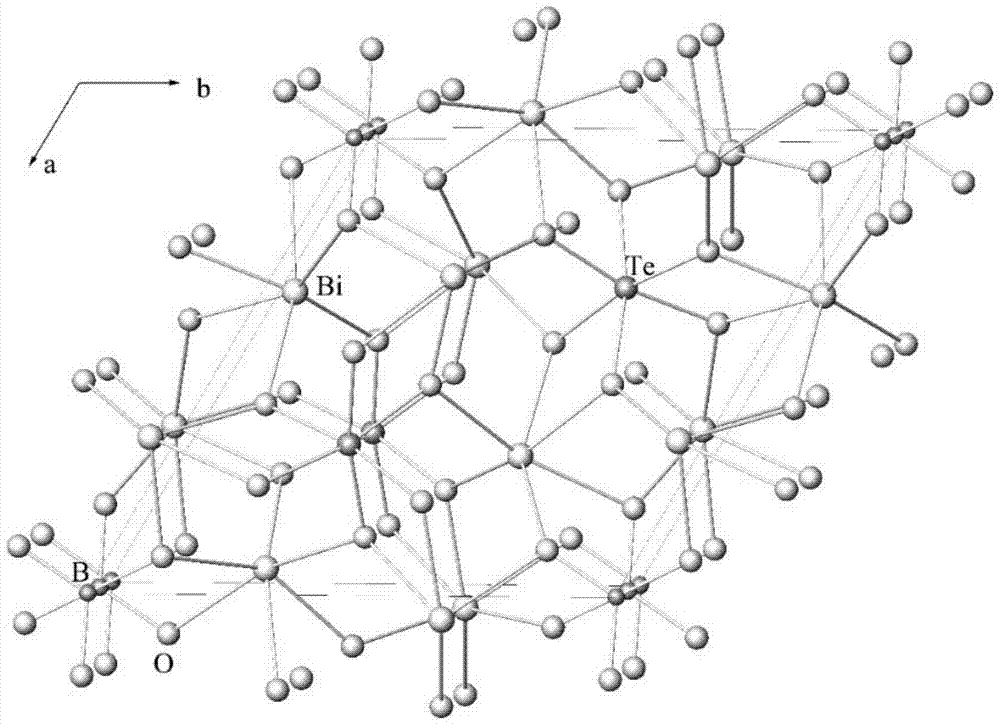

Bismuth tellurium borate compound, bismuth telluride borate nonlinear optical crystal, bismuth telluride borate scintillation crystal, preparation method and application

A technology of bismuth tellurium borate and scintillation crystals, applied in nonlinear optics, chemical instruments and methods, optics, etc., can solve the problems of expensive Lu elements, high growth temperature, etc., achieve wide transmission range, high electro-optic coefficient, and good mechanical properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Example 1 Preparation of polycrystalline Bi 3 TeBO 9 Compound

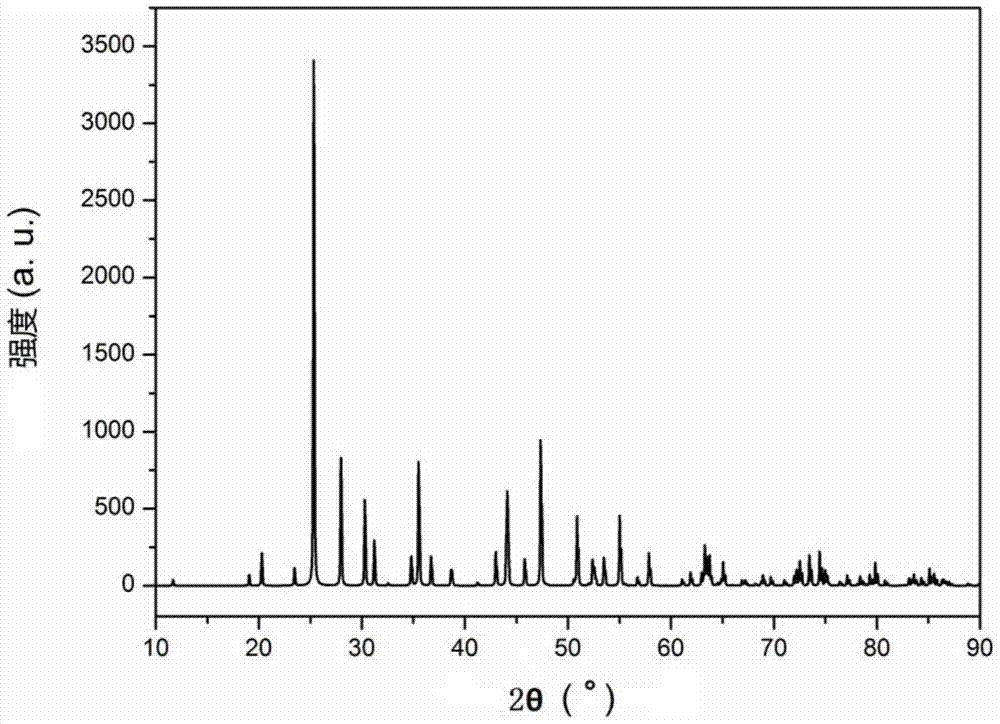

[0044] Prepared by solid phase reaction method, the reaction equation is 3Bi 2 O 3 +2TeO 2 +2H 3 BO 3 =2Bi 3 TeBO 9 ; The ratio of the above three reagents: Bi 2 O 3 (13.977g, 0.03mol), TeO 2 (3.192g, 0.02mol), H 3 BO 3 (1.237g, 0.02mol); the specific preparation steps are: weigh the reagents according to the above dosages, put them in a mortar, grind and mix them, then put them into a platinum crucible, put them in a muffle furnace, and The temperature is increased to 500℃ for pre-sintering at a rate of ℃ / h, and the temperature is kept for 24h, and then cooled. After cooling, the sample is taken out, re-ground and mixed, and then placed in a muffle furnace at 700℃ for 48h to obtain polycrystalline Bi 3 TeBO 9 Compound, Bi 3 TeBO 9 The XRD pattern of the compound is as figure 2 Shown.

Embodiment 2

[0045] Example 2 Preparation of Bi by flux method 3 TeBO 9 Nonlinear optical crystal

[0046] Use TeO 2 As a flux, the molar ratio of solute to flux is 1:0.5. Weigh 279.54g Bi 2 O 3 (0.6mol), 24.74g H 3 BO 3 (0.4mol) and 47.88g TeO 2 (0.3mol), after grinding and mixing in a mortar, melted into a crucible of Φ60mm×60mm in batches; put the crucible after dissolving into a vertical crystal growth furnace, heated to 800℃, and stirred at constant temperature After 48h, the temperature is then lowered to 5°C above the saturation point, the seed crystal is introduced to cool down at a rate of 1°C / day, and the rotation speed is 15r / min to start the crystal growth. After the crystal growth is completed, the seed rod is lifted to lift the crystal out of the liquid Then, the temperature is reduced to room temperature at a rate of 30℃ / h to obtain a transparent Bi 3 TeBO 9 Non-linear optical crystal.

Embodiment 3

[0047] Example 3 Preparation of Bi using flux top seeding method 3 TeBO 9 Nonlinear optical crystal

[0048] Use TeO 2 -B 2 O 3 As a flux, the molar ratio of solute to flux is 1:1:0.5. Weigh 559.08gBi respectively 2 O 3 (1.2mol), 98.93g H 3 BO 3 (1.6mol) and 255.36g TeO 2 (1.6mol), after grinding and mixing in a mortar, melt it in batches and put it into a Φ70mm×70mm crucible; put the crucible after dissolving into a vertical crystal growth furnace, heat up to 750℃, stir at constant temperature After 48h, the temperature is then lowered to 10℃ above the saturation point, the seed crystal is introduced, the seed crystal is just in contact with the liquid surface, and then the temperature is lowered at a rate of 0.5℃ / day, and the rotation speed is 25r / min to start crystal growth. After the crystal growth ends , The crystal is lifted from the liquid surface, and then the temperature is reduced to room temperature at a rate of 20℃ / h to obtain a transparent Bi 3 TeBO 9 Non-linear opti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com