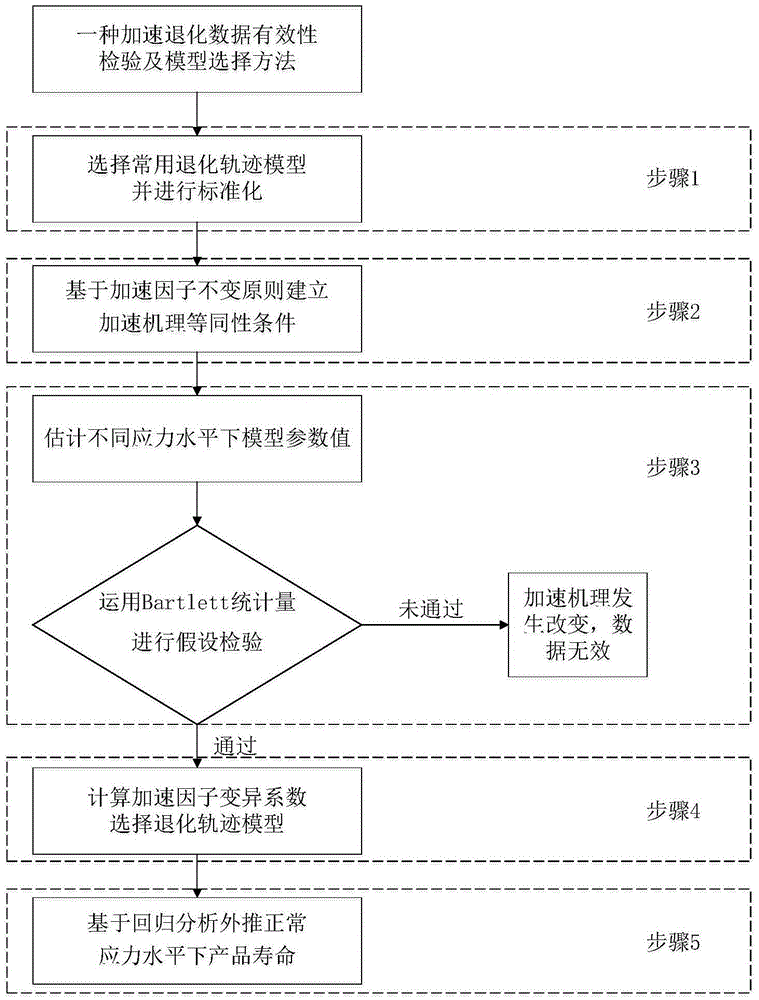

Accelerated degradation data validity testing and model selection method

A data validity and accelerated degradation technology, applied in the direction of electrical digital data processing, special data processing applications, instruments, etc., can solve the problems of unreasonable degradation model processing test data, less validity of accelerated degradation test data, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0075] The present invention will be described in further detail below in conjunction with accompanying drawings and examples.

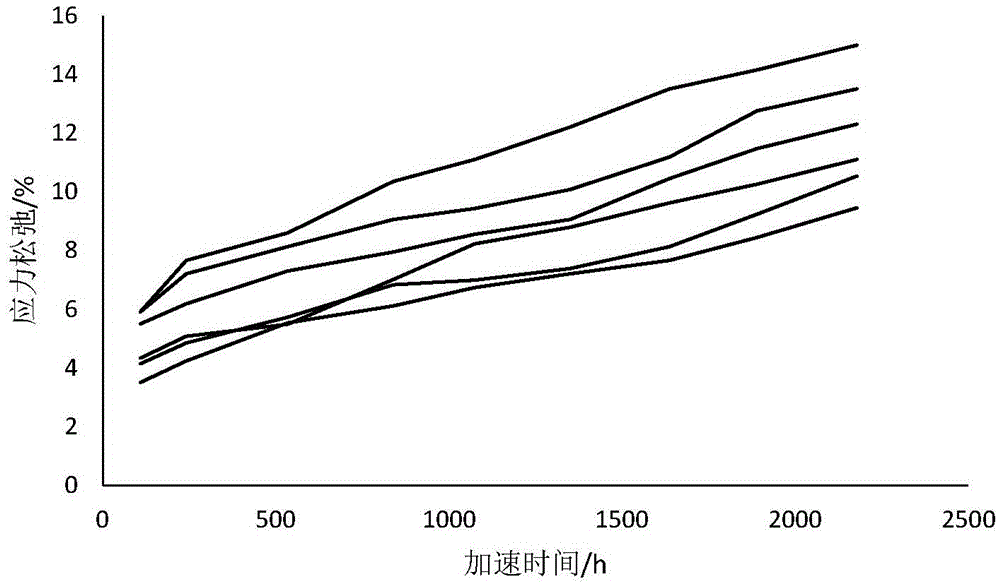

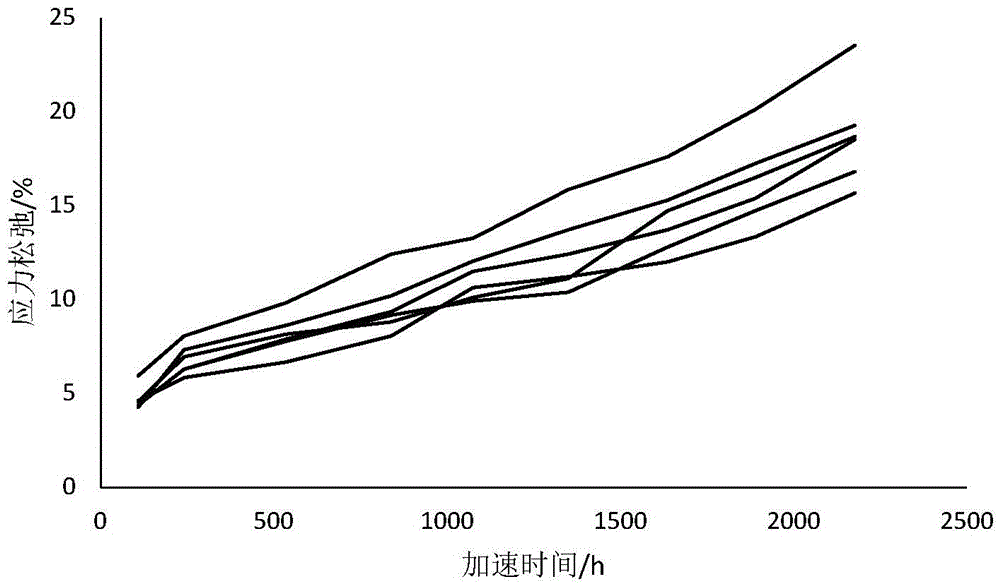

[0076] The main cause of failure of an electronic device is the degradation of the contacts of the internal electrical connector due to stress relaxation. The degradation process is mainly affected by temperature. Therefore, the constant temperature stress accelerated degradation test method was used to study the performance degradation of the electronic device. In three sets of accelerated stresses T 1 =65℃、T 2 =85°C and T 3 = Perform performance degradation test at 100°C, and put 6 samples under each stress. Table 2 records the detection time and the stress relaxation data of the samples under three groups of different accelerated stresses. The failure threshold of the electronic device is defined as the stress relaxation exceeding 30%, ie D=30.

[0077] Table 2 Stress relaxation data of an electronic device

[0078]

[0079] According to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com