Seeding device

A seeding device and seed technology, applied in the directions of planter parts, interval-type quantitative seeding machines, etc., can solve the problems of manual weeding, difficult management, inconsistent seedling density, etc., to save labor in management, avoid duplication of labor, improve The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

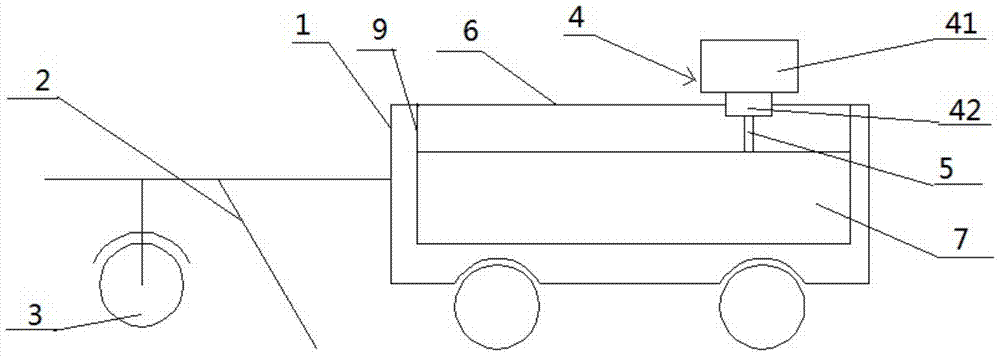

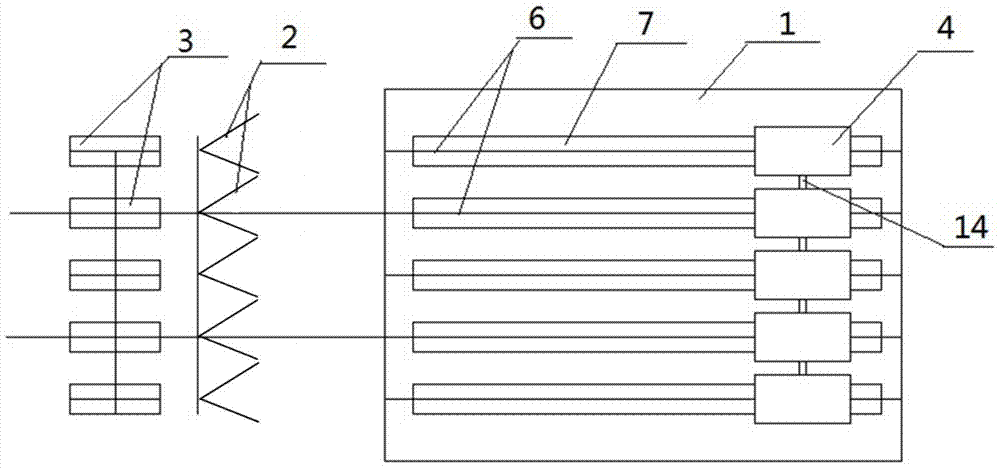

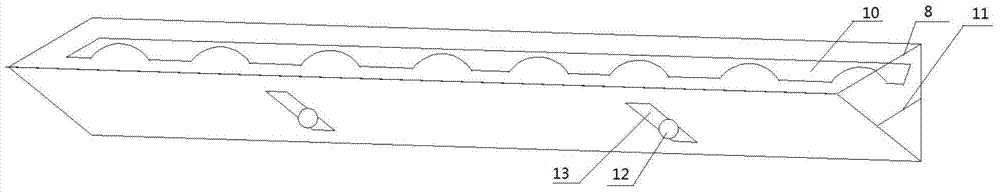

[0018] Such as Figure 1-4 As shown, the sowing device includes a frame 1, a sowing component, a cover plate 2 and a pressing wheel 3, and the sowing component includes a seed grading box 4, a conduit 5, a track 6, a servo motor, a controller, and a V-shaped device 7 , hydraulic connecting rod 8, hydraulic telescopic rod 9, slide bar 10, described track 6 is fixed on the frame 1, and described seed classification case 4 comprises seed bin 41 and seed classifier 42, and described seed bin 41 and The seed classifier 42 is connected, and the lower end of the seed classifier 42 is provided with a conduit 5; the seed classifier box 4 can slide on the track 6; the track 6 and the servo motor are connected with the frame 1; the control The device is used to control the moving speed of the seed grading box 4 on the track and the seed flow of the seed grading box; the V-shaped device 7 includes two side plates, and the top two sides of the two side plates of the V-shaped device are hyd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com