High-rise-building safe escaping device

An escape device and building technology, applied in life-saving equipment, building rescue, etc., can solve the problems of inconvenient carrying, high manufacturing cost, heavy weight, etc., and achieve the effects of simple structure, shortened escape time, and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

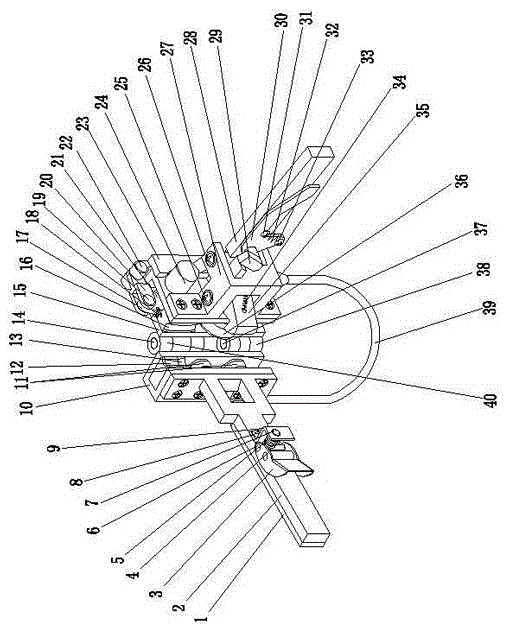

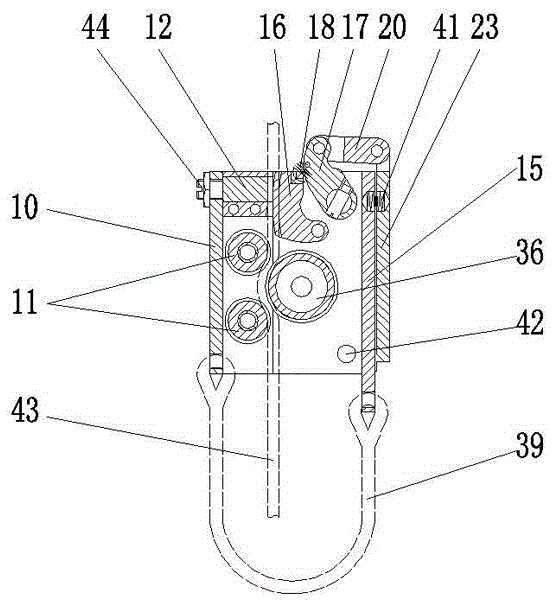

[0020] The specific embodiment of the present invention is, with reference to figure 1 , figure 2 , including a pulley frame, a handle, a lock assembly, a slow-down assembly, an escape rope and a sling cover, the pulley frame includes a fixed pulley frame, a movable pulley frame, an upper folding shaft, and a lower folding shaft, wherein the fixed Pulley frame 10 and movable pulley frame 15 are hinged by upper hinge shaft 14 and lower hinge shaft 37, and described handle comprises fixed pulley frame handle 2, movable pulley frame handle 28, movable pulley frame handle seat 27, and the fixed pulley Frame handle 2 is connected with the said pulley frame 10, and said movable pulley frame handle seat 27 is connected with said movable pulley frame 15, and said movable pulley frame handle 28 is hinged with said movable pulley frame handle seat 27 by pin 26 , the lock assembly includes a lock 35, a pin 25, an extension spring 34 and a lock lock assembly, the lock 35 is hinged with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com