Plastic combined firework

A combination of fireworks and plastic technology, applied in pyrotechnics, offensive equipment, weapon types, etc., can solve the problems of large base size, low work efficiency, and labor-intensive, etc., to solve the problem of inconvenient installation, fast operation speed, and long time-consuming Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

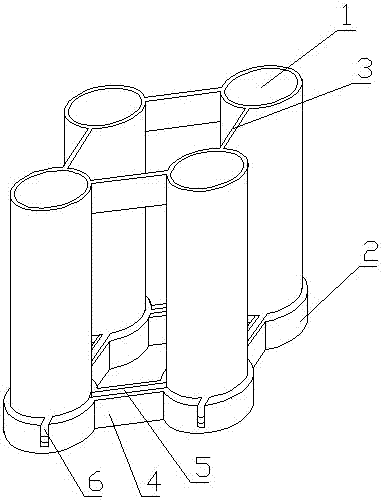

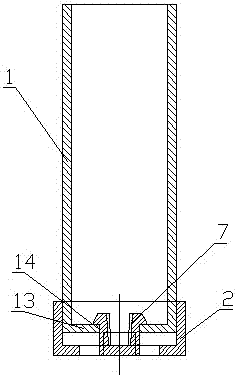

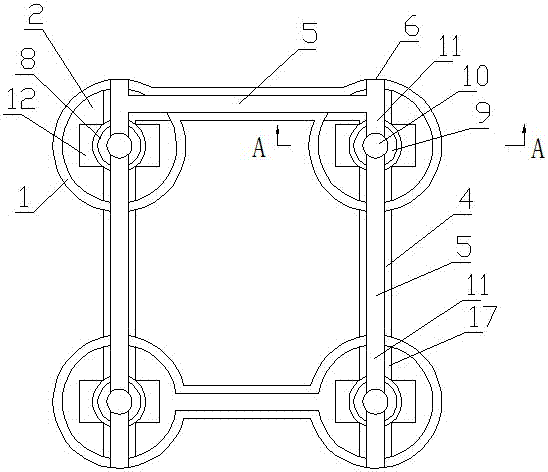

[0024] Such as Figure 1-4 As shown, a plastic composite firework comprises several plastic launch tubes 1 and plastic bases 2, the plastic launch tube 1 is a hollow cylinder with a plastic bottom plate 13 at one end, and a connecting hole is provided in the center of the plastic bottom plate 13 14. The plastic launching tube 1 is located above the plastic base 2, and the bottom end of the plastic launching tube 1 is installed on the plastic base 2.

[0025] A connecting device 7 is provided at the center of the plastic base 2 , and the connecting device 7 protrudes into a connecting hole 14 at the center of the plastic bottom plate 13 and forms a snap fit with the connecting hole 14 . The connecting device 7 includes a left connecting head 8, a right connecting head 9, a left connecting body 15, a right connecting body 16, a first lead wire groove 11, and a gunpowder hole 10, and the tops of the left connecting body 15 and the right connecting body 16 are respectively A left...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com