High-temperature resisting perpetuum mobile type hydroelectric generation exhausting robot

A robotic and high-temperature-resistant technology, applied in fire rescue and other fields, to achieve the effects of avoiding water leakage, efficient use of water pressure, and simple design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

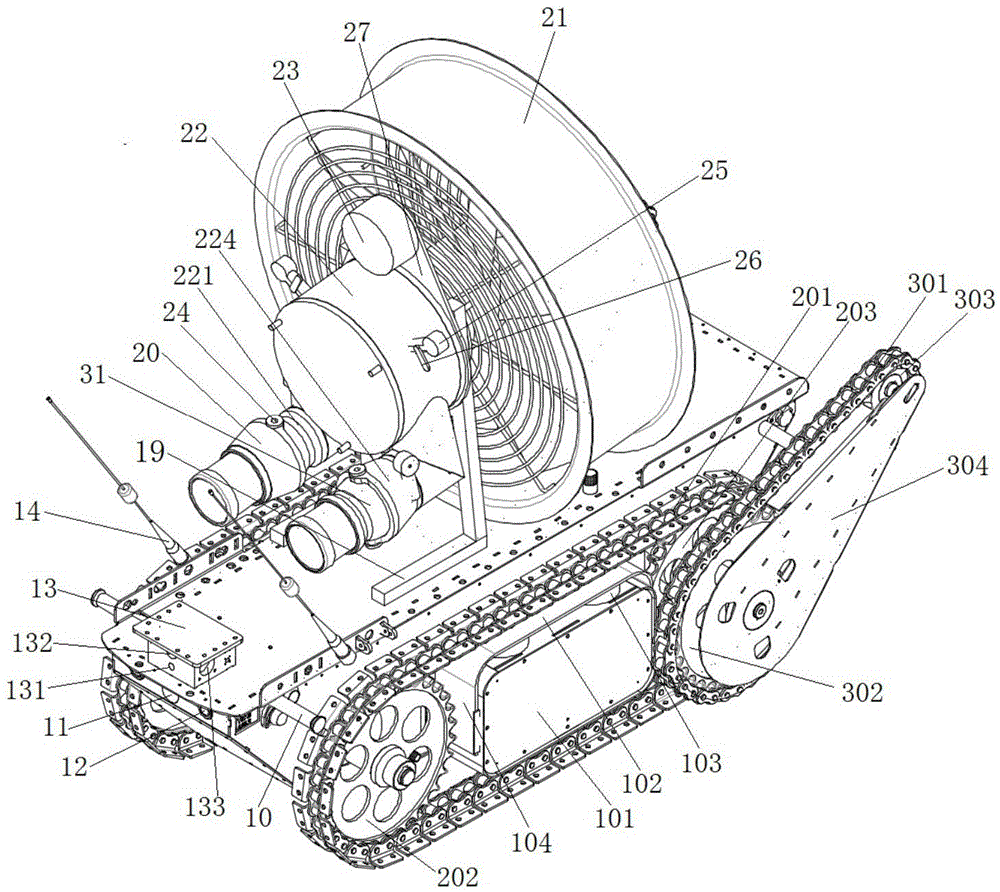

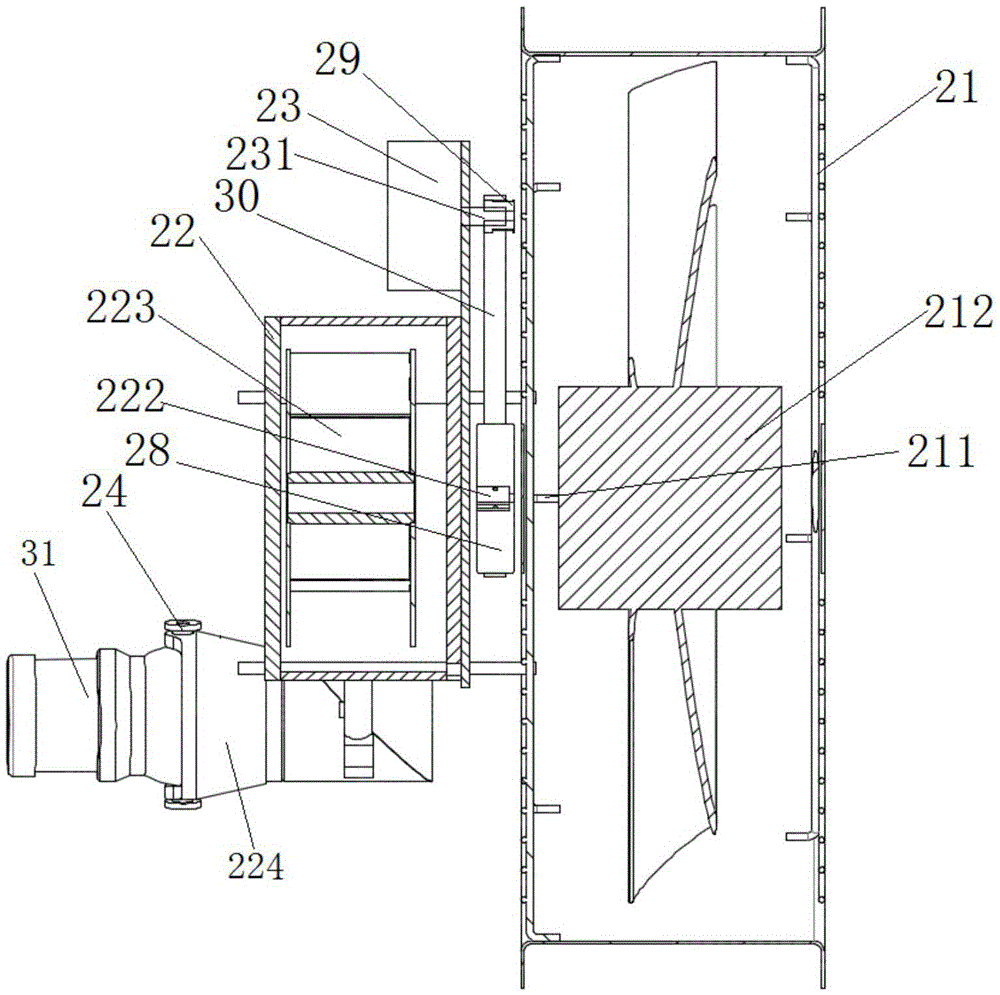

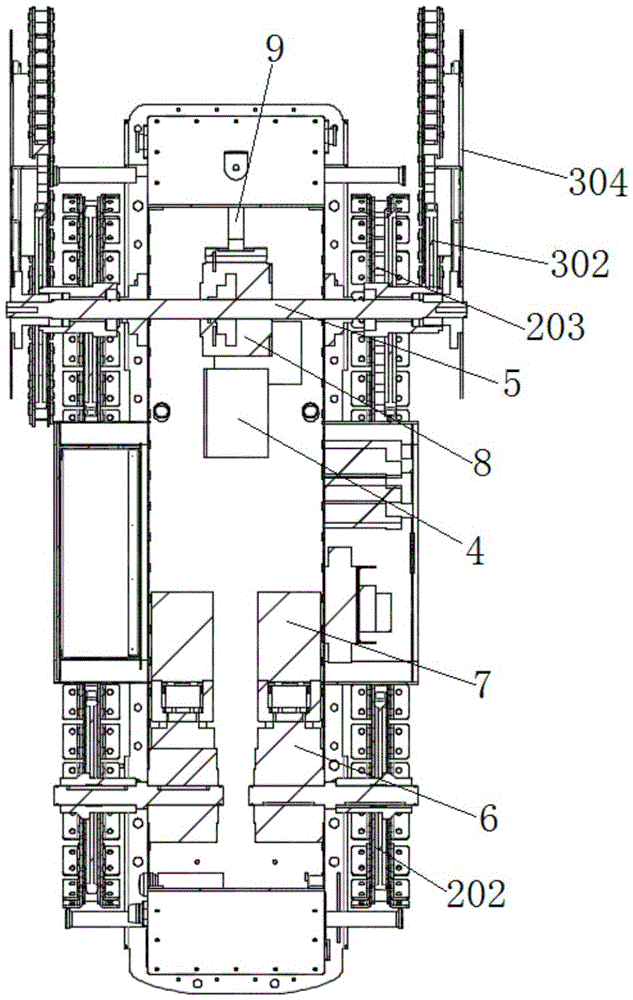

[0035] combine figure 1 , figure 2 with image 3 , a high-temperature-resistant perpetual-moving hydropower smoke-exhausting robot in this embodiment includes a wheel-track robot platform, and the wheel-track robot platform includes a chassis cabin 1 and crawler belt walking mechanisms located on the left and right sides of the chassis cabin 1, In this embodiment, the front and rear sides of the chassis cabin body 1 are inwardly inclined slopes, which improve the obstacle-surmounting ability of the robot platform; the crawler walking mechanism includes chassis anti-corrosion metal crawlers 201, chassis driving wheels 202 and side panels with the chassis cabin body 1 The chassis driven wheel 203 connected by rotation, the anti-corrosion metal track 201 of the chassis has the advantages of high temperature resistance and corrosion resistance, and has the ability of secondary survival under high temperature, explosion and strong corrosion environment. In this embodiment, the an...

Embodiment 2

[0040] The basic structure of a high-temperature-resistant perpetual-moving hydropower smoke-exhausting robot in this embodiment is the same as in Embodiment 1, except that two symmetrical metal fin arms are arranged on the outside of the two crawler walking mechanisms, and the crawler walking mechanisms are combined with metal fin arms. The fin arm enables the wheel-track robot platform to move forward and backward, and can improve the ability to climb and overcome obstacles, and is flexible and convenient to operate; the metal fin arm includes the fin arm anti-corrosion metal track 301, the fin arm metal bracket 304, and the chassis from The fin arm driving wheel 302 fixedly connected to the driving wheel 203 and the fin arm driven wheel 303 rotationally connected with the fin arm metal bracket 304, the fin arm anti-corrosion metal crawler 301 has the advantages of high temperature resistance and corrosion resistance, and can be used in high temperature, explosion and strong c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com