Loading mechanism for rivet sheet feed device

A feeder and load-carrying technology, which is applied in the field of load-carrying mechanisms for rivet sheet feeders, can solve problems such as restricting work efficiency and unfavorable automatic production, and achieves the effects of improving production efficiency, realizing unattended operation, and meeting processing needs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

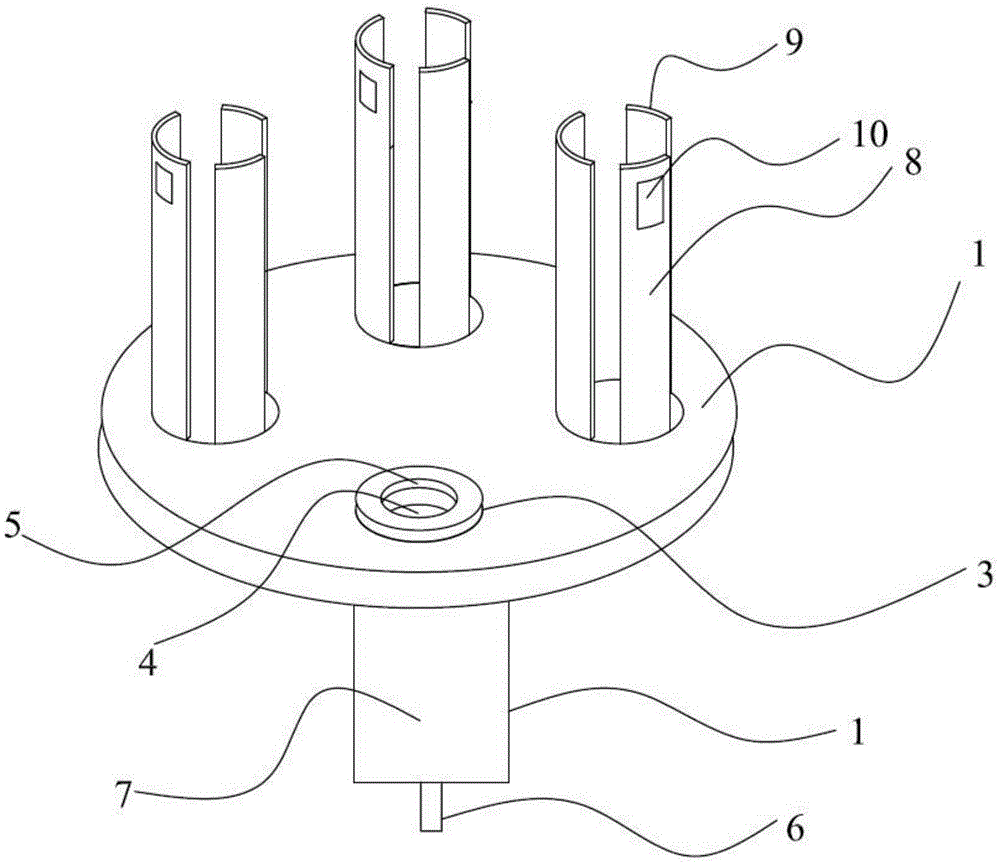

[0016] A loading mechanism for a rivet feeder, such as figure 1 As shown, it includes a base 1 and a disc-shaped main body 2 on the base 1. The main body 2 is fixed with several (four in this embodiment) centrally symmetrical stages 3, and the stage 3 is an annular stage. The main body 2 is provided with a working hole 4 that runs through the main body 2 at the stage 3, and the stage 3 is provided with a through hole 5 that matches the working hole 4; the diameter of the working hole 4 is the same as that of the through hole 5; the base 1 is provided with a rotating shaft 6 and a motor 7 for driving the rotating shaft 6, and the upper part of the rotating shaft 6 is connected with the center of the main body 2.

[0017] The carrier 8 is fixed on the carrier platform 3, and the carrier 8 is composed of several (3 pieces in this embodiment) vertical arc-shaped support plates 9, the support plates 9 are arranged at intervals, and the ring Surround on the side wall of the stage 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com