Building construction welder and operation method thereof

A technology for building construction and operation methods, applied in welding equipment, manufacturing tools, metal processing equipment, etc., can solve the problems of affecting welding function, complex structure, inconvenient use and installation, etc., to maintain safe use, good welding effect, and processing high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

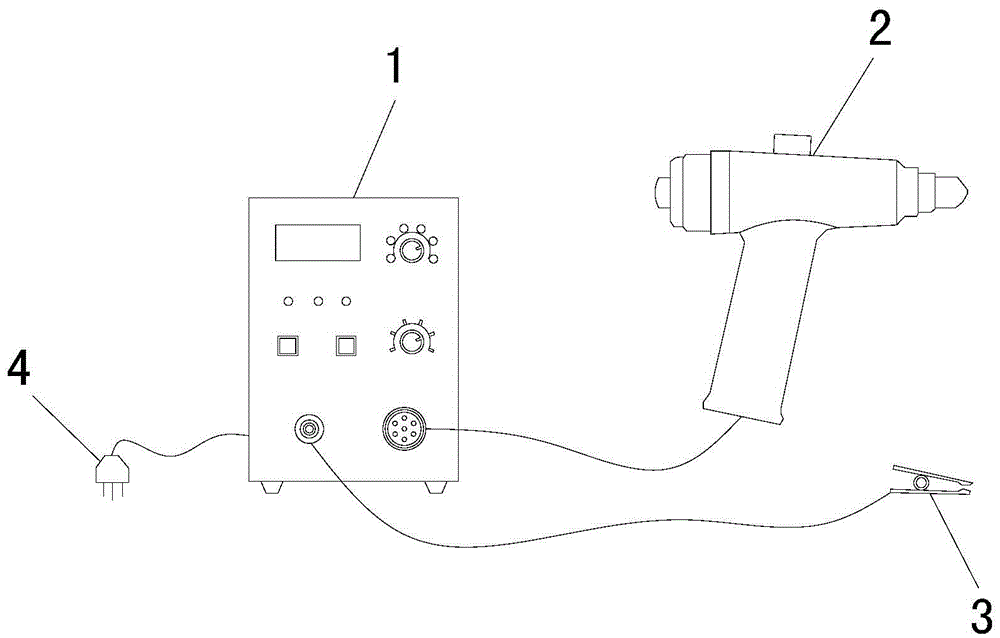

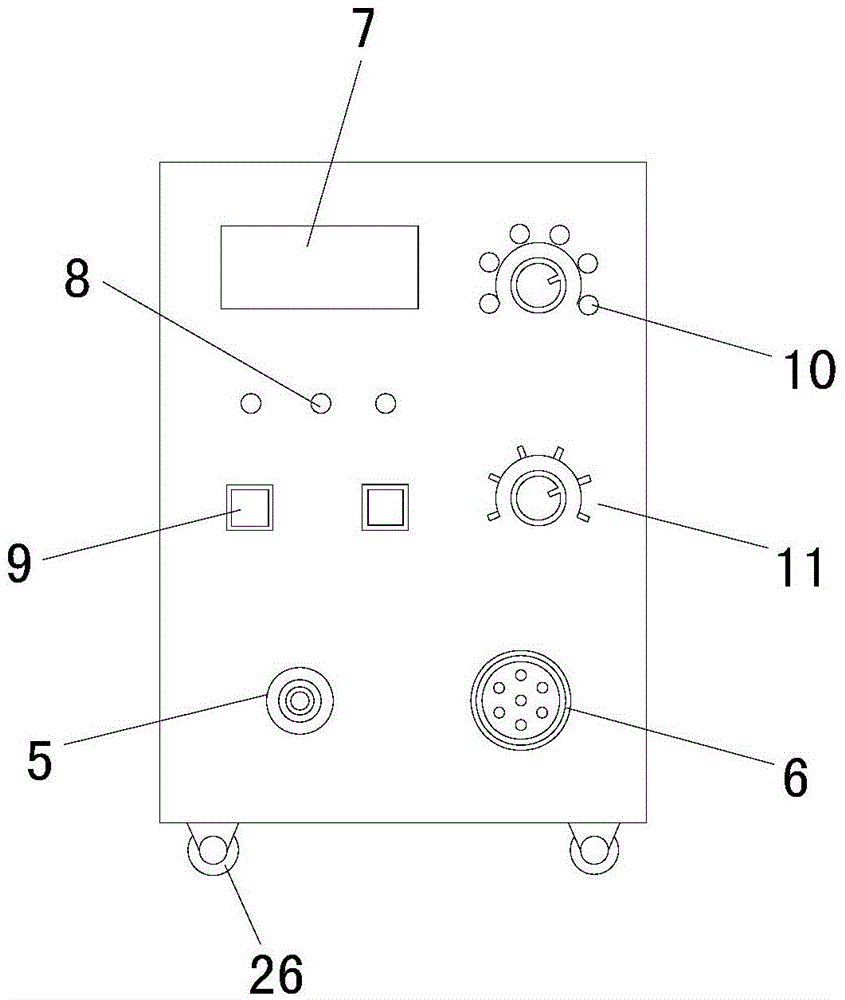

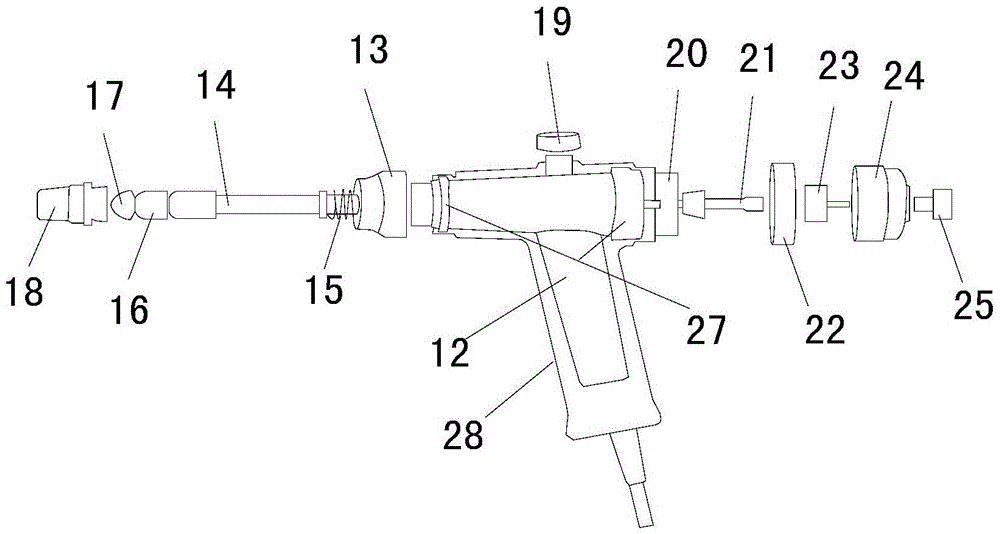

[0025] Such as Figure 1-3 As shown, a welding machine for building construction and its operation method include a host 1, a spray gun 2, a grounding clip 3 and a host power cord 4, the host power cord 4 is electrically connected to the host 1, and the host 1 is A connection terminal 5 and a cable socket 6 are provided, the connection terminal 5 is electrically connected to the grounding clamp 3, the cable socket 6 is electrically connected to the spray gun 2, and the host 1 is also provided with a voltage display window 7, indicating Light 8, power button 9, current adjustment knob one 10 and current adjustment knob two 11, described spray gun 2 comprises shell 28, water tank shell 12, nut 13 and evaporator 14, and described water tank shell 12 is located at shell 28, the evaporator 14 is fixedly connected to the water tank housing 12 through a nut 13, a spring 15 is arranged on the outside of the evaporator 14, and a vortex generator 16, a nozzle 17 and a sleeve are arrange...

Embodiment 2

[0038] Such as Figure 1-3As shown, a welding machine for building construction and its operation method include a host 1, a spray gun 2, a grounding clip 3 and a host power cord 4, the host power cord 4 is electrically connected to the host 1, and the host 1 is A connection terminal 5 and a cable socket 6 are provided, the connection terminal 5 is electrically connected to the grounding clamp 3, the cable socket 6 is electrically connected to the spray gun 2, and the host 1 is also provided with a voltage display window 7, indicating Light 8, power button 9, current adjustment knob one 10 and current adjustment knob two 11, described spray gun 2 comprises shell 28, water tank shell 12, nut 13 and evaporator 14, and described water tank shell 12 is located at shell 28, the evaporator 14 is fixedly connected to the water tank housing 12 through a nut 13, a spring 15 is arranged on the outside of the evaporator 14, and a vortex generator 16, a nozzle 17 and a sleeve are arranged...

Embodiment 3

[0051] Such as Figure 1-3 As shown, a welding machine for building construction and its operation method include a host 1, a spray gun 2, a grounding clip 3 and a host power cord 4, the host power cord 4 is electrically connected to the host 1, and the host 1 is A connection terminal 5 and a cable socket 6 are provided, the connection terminal 5 is electrically connected to the grounding clamp 3, the cable socket 6 is electrically connected to the spray gun 2, and the host 1 is also provided with a voltage display window 7, indicating Light 8, power button 9, current adjustment knob one 10 and current adjustment knob two 11, described spray gun 2 comprises shell 28, water tank shell 12, nut 13 and evaporator 14, and described water tank shell 12 is located at shell 28, the evaporator 14 is fixedly connected to the water tank housing 12 through a nut 13, a spring 15 is arranged on the outside of the evaporator 14, and a vortex generator 16, a nozzle 17 and a sleeve are arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com