A water-discharging and cutting mechanism of the center of the high-speed spindle of a CNC machine tool

A technology of central water outlet and high-speed spindle, which is applied in the direction of metal processing machinery parts, clamping, support, etc., to achieve high signal acquisition stability, convenient assembly and maintenance, simple and compact structure and the effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

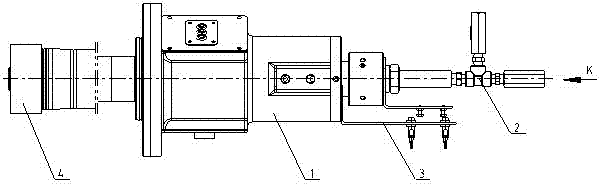

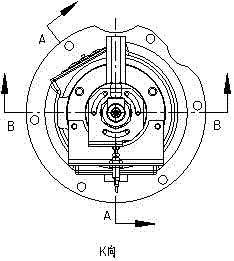

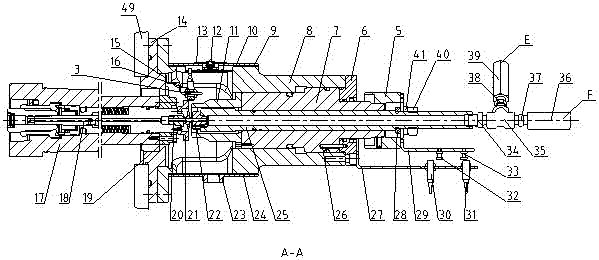

[0026] Below in conjunction with accompanying drawing, the present invention will be further described: Figure 1 ~ Figure 4 Known, a high-speed main shaft center water knife punching mechanism includes a knife punching device assembly 1 , a central water outlet assembly 2 , a detection assembly 3 and a spindle assembly 4 . The oil cylinder housing 8 and the flange A14 in the knife beating device assembly 1 are connected with the main shaft housing 49 by means of fasteners; The adjusting pad 28, the spring washer 41 and the locking nut 40 fix the position of the mounting plate 29, and the fixed mounting plate 29 is installed on the nut bumper 5 at the tail of the knife device assembly 1 by means of fasteners; the detection assembly 3 The signal board A15 of the tool with or without detection is installed on the flange A14 in the tooling device assembly 1, and its signal block is the flange B21 in the spindle assembly 4; the signal board B27 for the detection of the tooling sig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com