Stiffeners for casting light-metal door headers

A reinforcement, light metal technology used in doors, vehicle components, transportation and packaging to solve problems such as not being very effective, increasing bending stiffness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The following discussion of embodiments of the invention for reinforcement of cast light metal lintels is merely exemplary in nature and in no way intended to limit the invention or its application or use.

[0048] figure 1 is an illustration of a vehicle door 10 , where door 10 is a left side door as viewed from the left outside of the vehicle. The door 10 includes a lintel 12 , which is the area above the window of the door 10 . The lintel 12 has the narrowest cross-section of any part of the door 10 . Additionally, the lintel 12 is subject to lateral stiffness specifications, which can vary by geographic region. For example, in developed regions of the world with highway infrastructure, the lintel 12 may be required to exhibit a lateral load of less than 3 millimeters (mm ) for lateral deflection. In other parts of the world, lintel stiffness specifications can be less stringent.

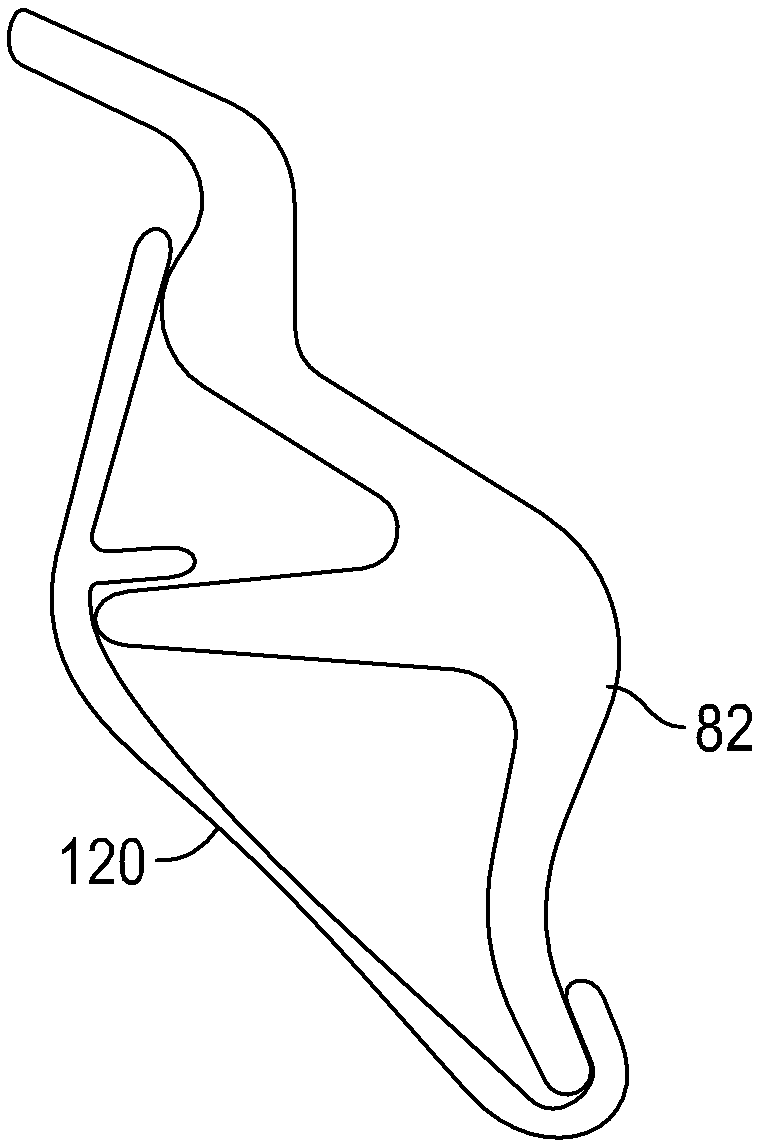

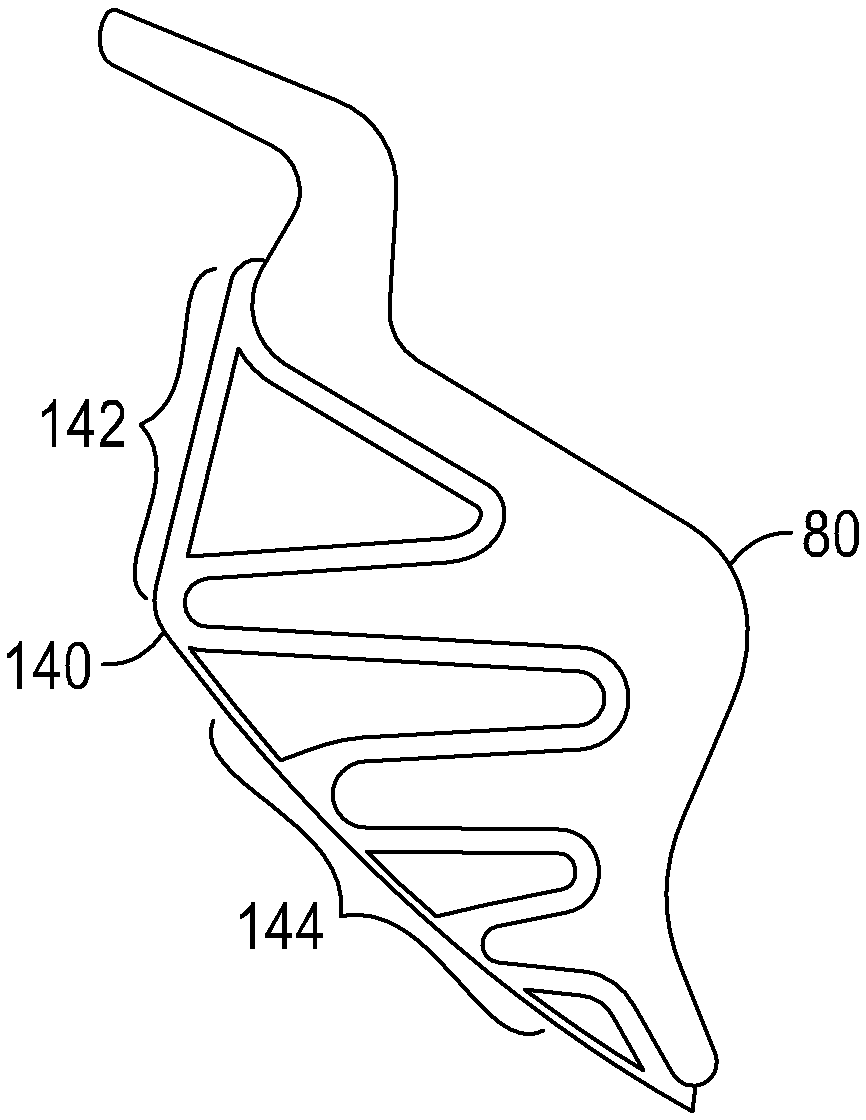

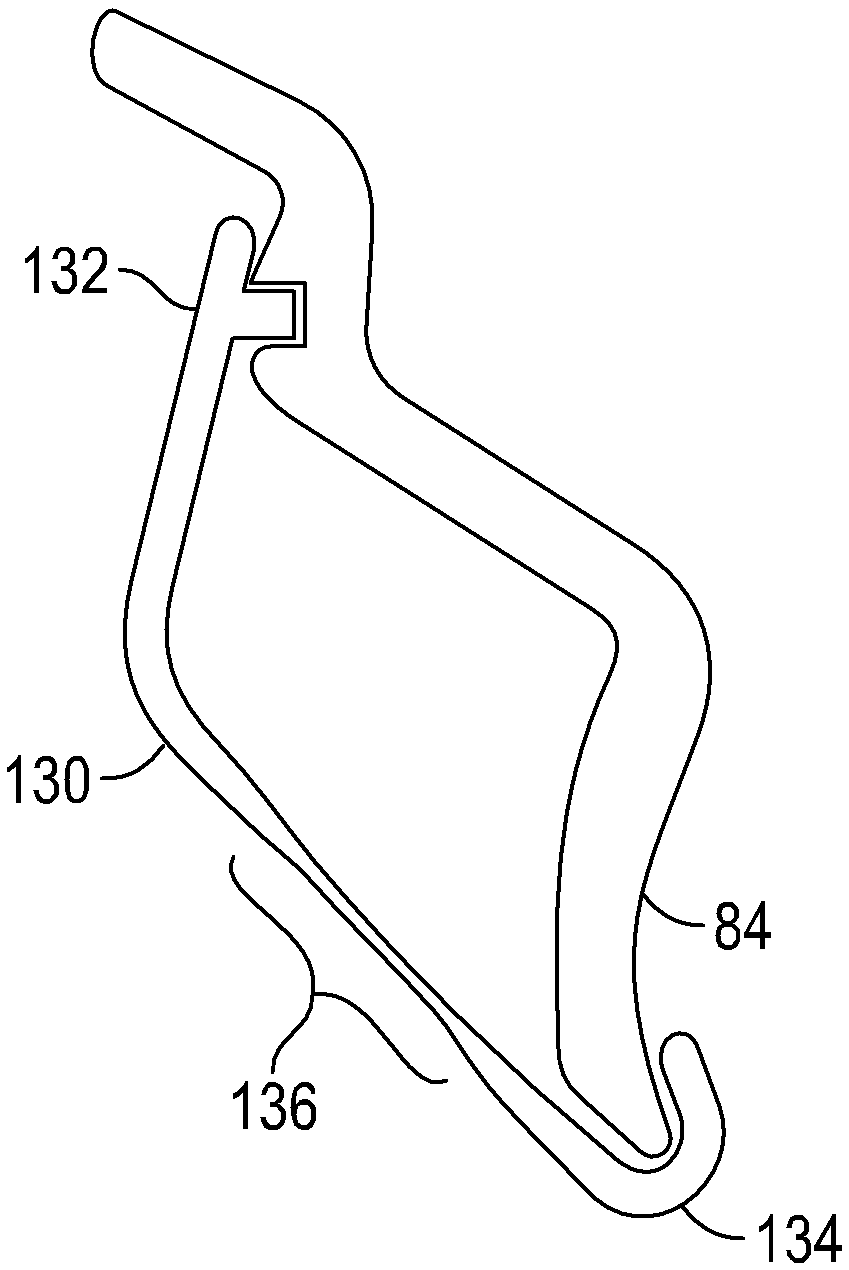

[0049] figure 2 is a cross-sectional illustration of a traditional lintel and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com