Less effort speed changer

An accelerator and force technology, which is applied in the direction of vehicle gearbox, wheel transmission, transportation and packaging, can solve the problems of labor-saving and unsafe, and achieve the effect of simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with accompanying drawing by embodiment:

[0028] preferred embodiment

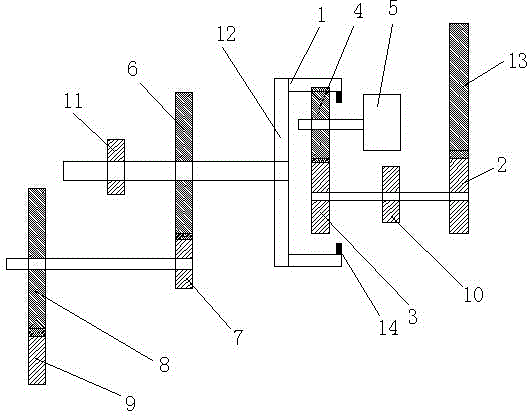

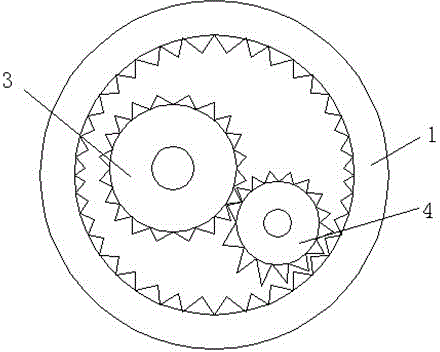

[0029] Such as figure 1 As shown, the present invention achieves the purpose of labor saving and speed change through the connection and driving of each gear, and specifically includes a ring structure with an internal gear, that is, an annular internal gear, and two external gears are arranged inside it, that is, an external gear-one It meshes with external gear 2, external gear 1 and external gear 2, wherein external gear 1 is connected with external pinion 1 and rotates synchronously, and external gear 1 is driven by a power device. The power device here can be driven by manpower or Mechanical drive (including electric drive, wind drive, etc.), the pinion one drives the outer gear one to rotate synchronously, and then drives the second outer gear to rotate, the second outer gear meshes with the annular inner gear to drive the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com