Combining process for topside structures and hull structures of tension leg platforms

A tension leg platform and floating body technology, which is applied to ship parts, ships, transportation and packaging, etc., can solve the problems of high cost, not too large wind and waves, and high risk of offshore operations, so as to reduce risk, reduce construction period and cost, The effect of improving the closing efficiency of the final assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

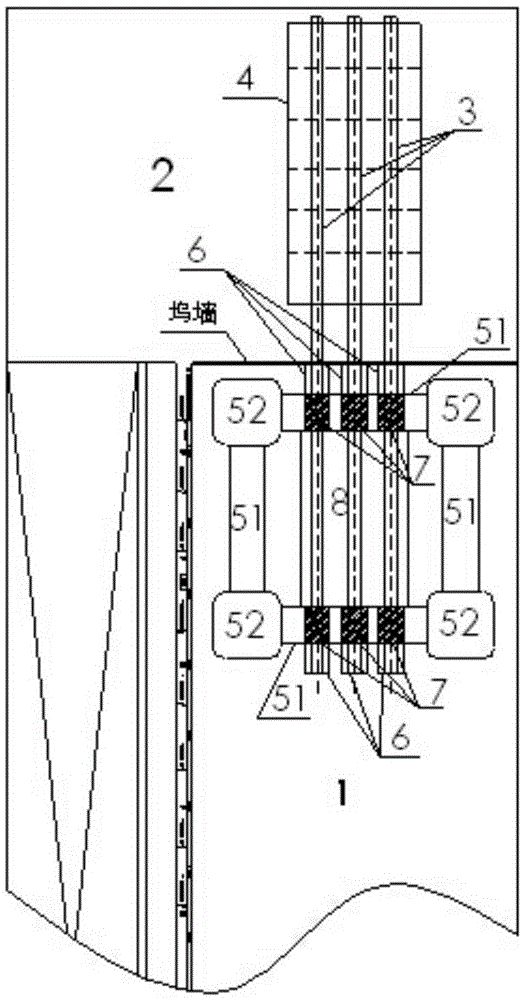

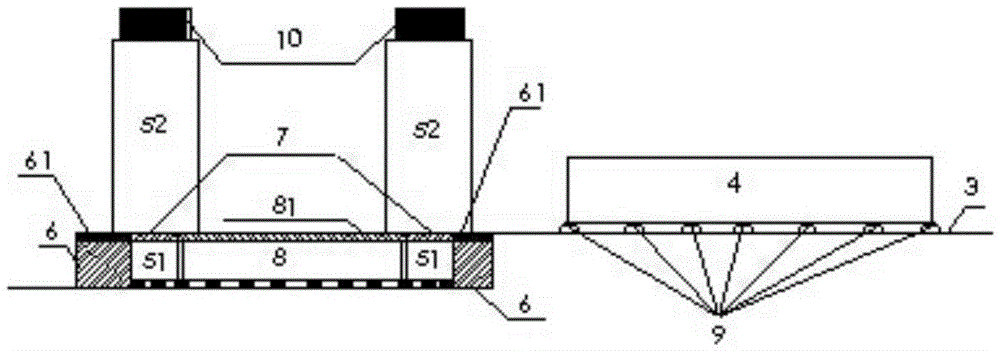

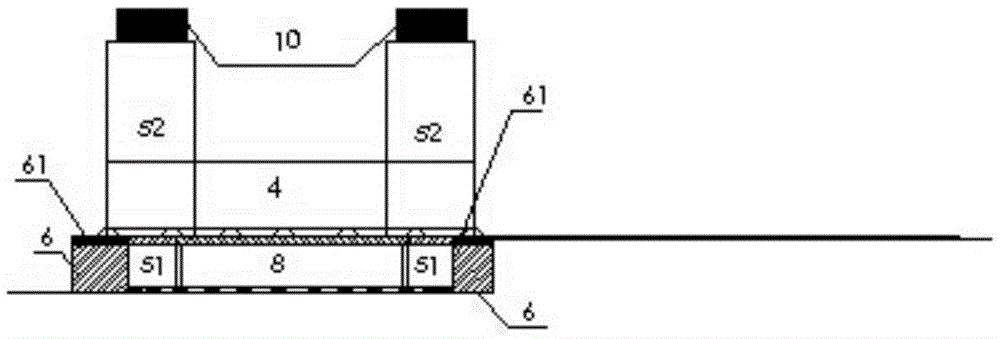

[0028] like figure 1 — Image 6 Shown, the present invention adopts following steps:

[0029] The first step: Lay the load-bearing slideway 3 on the assembly platform 2 next to the dock 1, and then build the upper module 4 of the tension leg platform 51 on the load-bearing slideway 3; meanwhile, build the lower floating body 5 in the dock 1;

[0030] Wherein, the upper module 4 is closed on the assembly platform 2 next to the dock, and the lower floating body structure 5 is closed in the dock 1, and the bearing slideway 3 and the hydraulic sliding shoe 9 are set at the lower part of the assembly platform module;

[0031] Step 2: Install a load-bearing truss 6 between the tension leg platform 51 and the dock 1 by means of bolt connection, and set a first slideway 61 on the load-bearing truss 6;

[0032] Step 3: set the second slideway 7 on the tension leg platform 51 by means of bolt connection;

[0033] Step 4: Set up a temporary barge box 8 between the lower floating body ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com