Retracting and releasing method of folding arm type propeller

A propeller and arm-type technology, which is applied in the field of retractable arm propellers, can solve the problems of the locking device being difficult to disengage, the impact of the hull, etc., and achieve the effect of solving the problem of being difficult to disengage and reducing frictional force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

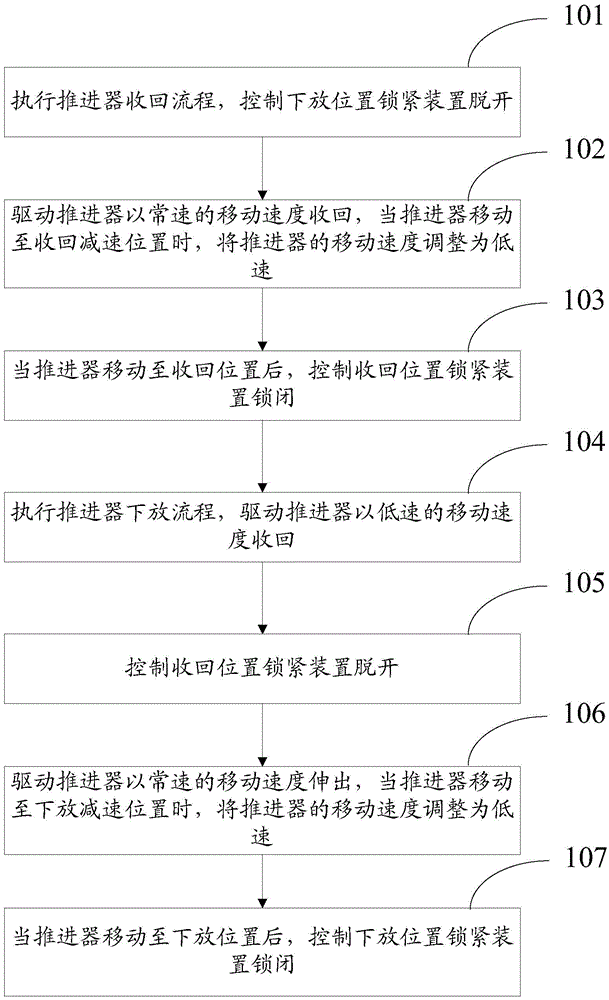

[0037] The embodiment of the present invention provides a method for retracting and retracting a folding-arm propeller, such as figure 1 As shown, the folding method includes:

[0038] Step 101: Execute the thruster retraction process, and control the locking device in the lowered position to disengage.

[0039] Step 102: Drive the propeller to retract at a normal moving speed, and adjust the moving speed of the propeller to a low speed when the propeller moves to a retracting deceleration position.

[0040] Step 103: After the pusher moves to the retracted position, control the retracted position locking device to lock.

[0041] Step 104: Execute the process of lowering the thruster, and drive the thruster to retract at a low speed.

[0042] Step 105: Control the retracted position locking device to disengage.

[0043] Step 106: Drive the propeller to extend at a constant moving speed, and adjust the moving speed of the propeller to a low speed when the propeller moves to ...

Embodiment 2

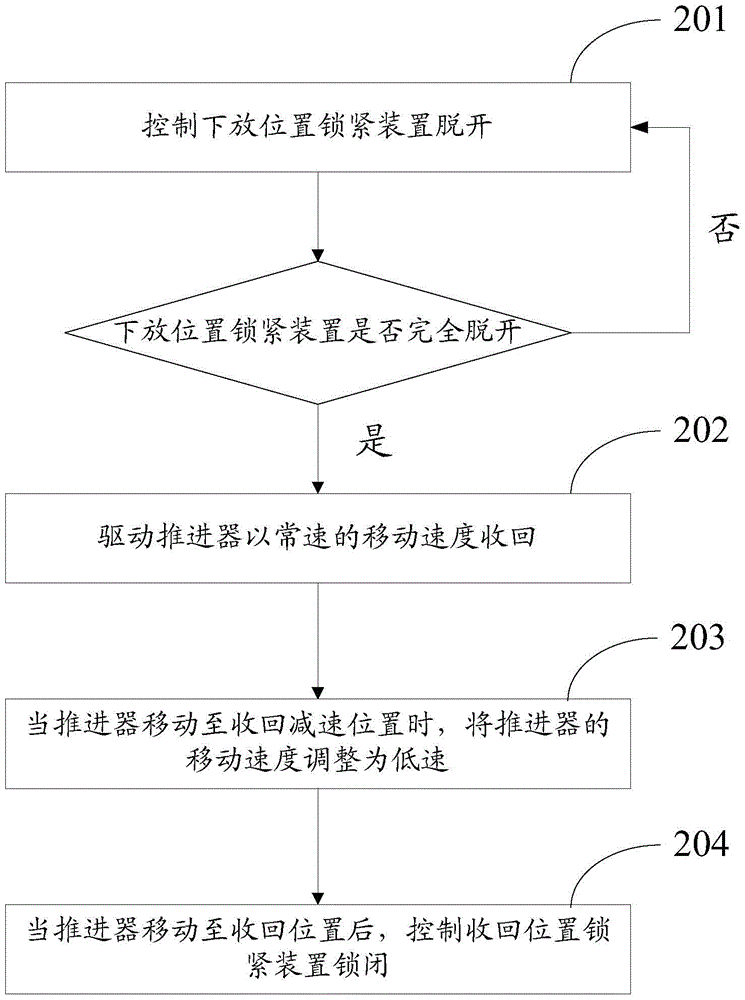

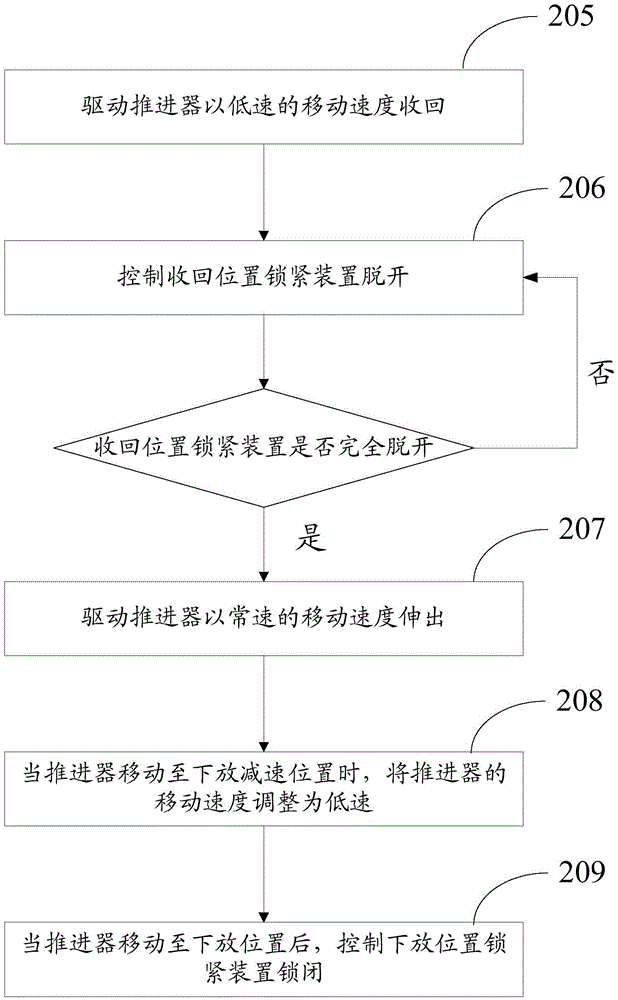

[0047] The embodiment of the present invention provides another retractable method of the folding arm propeller, see Figure 2-3 , the retraction method includes:

[0048] Step 201: Execute the thruster retraction process, and control the locking device in the lowered position to disengage.

[0049] During realization, the disengagement of the locking device in the lowering position is controlled by the lowering position telescopic oil cylinder.

[0050] Step 202: Drive the propeller to retract at a constant moving speed.

[0051] During implementation, the retraction of the propeller is controlled by the propeller telescopic oil cylinder.

[0052] Specifically, before driving the propeller, first check whether the lowering position locking device is completely disengaged by the position sensor unit, if it has been completely disengaged, enter step 202; if not completely disengaged, then repeat step 201 until the lowering position lock The tightening device is completely di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com