Inclination and shock preventing chemical box for aerial spraying

An aviation and anti-tilting technology, applied in the field of agricultural machinery, can solve the problems of unbalance and can not well prevent the liquid in the medicine box from tilting, and achieve the effects of preventing splashing, improving the utilization rate and reducing environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

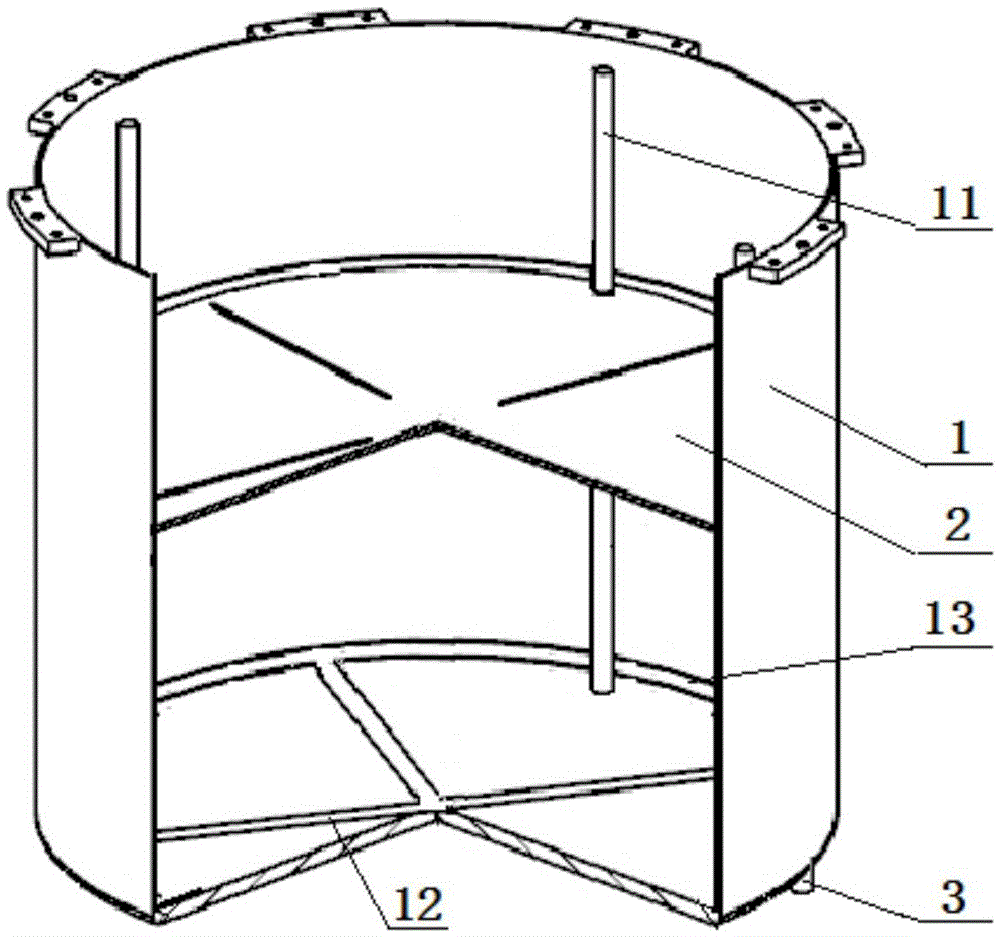

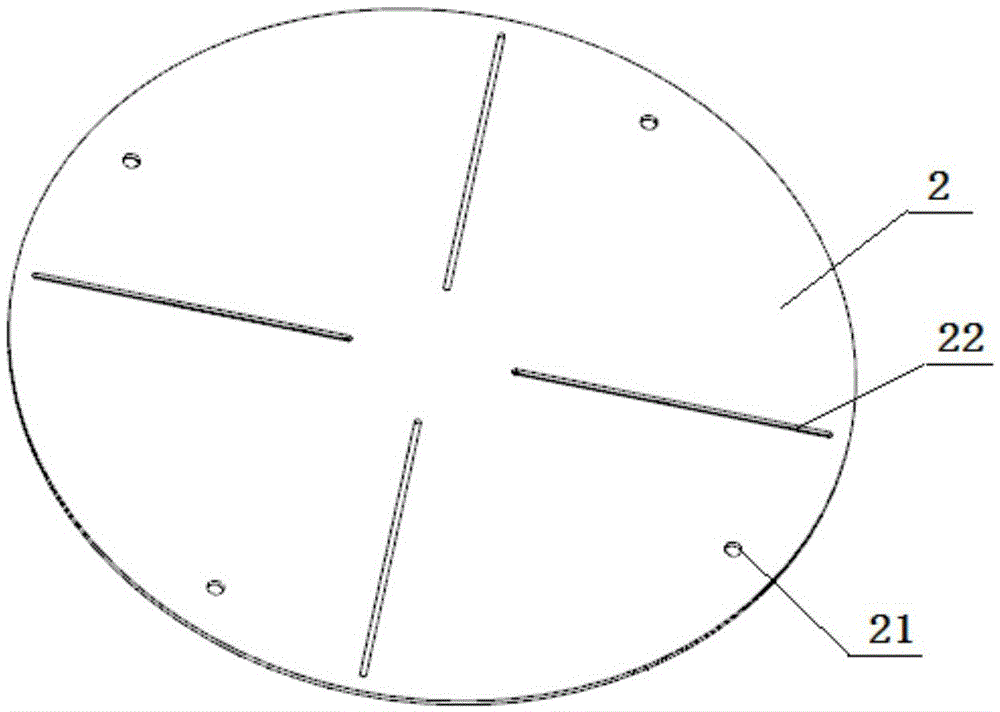

[0025] like Figure 4 , Figure 5 As shown, the liquid suction pipe 3 is connected to the casing 1 from the bottom surface of the casing 1, and the liquid suction pipe 3 is connected with the spray bar or the spraying device from the outside of the casing 1. Specifically, an annular groove 13 close to the tank wall is provided on the bottom surface of the box body 1, and several radial grooves 12 communicated with the annular groove 13, and the depth of the annular groove 13 is greater than that of the radial groove 12 depth, to ensure the sufficient supply and utilization of the liquid medicine in the aviation spraying operation; the annular groove 13 is externally connected with an even number of liquid suction pipes 3, and the even number of liquid suction pipes 3 are symmetrically distributed to ensure the stability of the aviation flight.

Embodiment 2

[0027] As a modification of Embodiment 1, a groove can also be provided at the center of the bottom surface of the box body 1, and several radial grooves 12 communicated with the central groove, the depth of the central groove is greater than that of the radial groove 12 The depth of the center groove externally connects the pipette 3. When the remaining amount of liquid medicine is small, the liquid medicine distributed at the bottom of the box can be collected in the central groove through the radial groove 12, which is easier to ensure that the liquid medicine is sucked away by the spray suction pipe and fully utilized, avoiding the waste of liquid medicine and To pollute the environment, and reduce the inconvenience of manually cleaning the remaining night of the medicine box.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com