A palladium/carbon catalyzed preparation method of 2,2'-bipyridine

A technology of bipyridine and carbon catalysis, which is applied in the fields of chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., which can solve the cumbersome separation of products and catalysts and the greater impact on product purity , environmental protection treatment and other problems, to achieve the effect of convenient recycling, reduce production cost and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

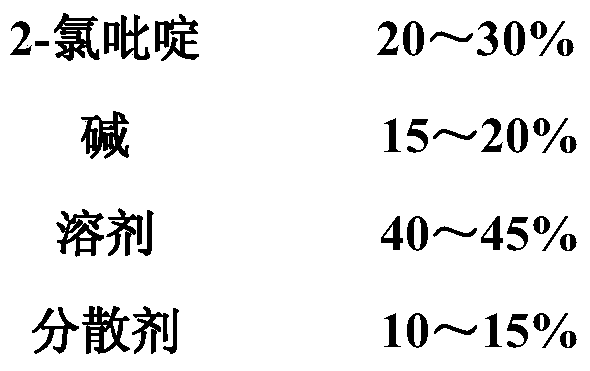

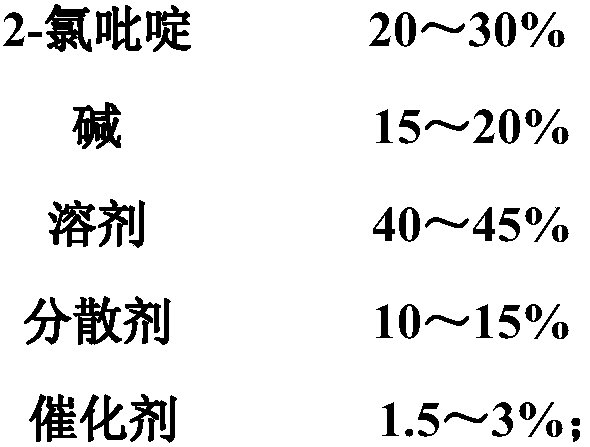

Method used

Image

Examples

Embodiment 1

[0018] Embodiment 1: prepare 1 1000mL reaction bottle, add 40g water first under nitrogen protection, then slowly add 40g (1mol) sodium hydroxide in this reaction bottle, make sodium hydroxide dissolve completely under stirring state. Add 56g of 2-chloropyridine to the reaction flask, and after stirring for 5 minutes, the color of the liquid in the reaction flask changes from colorless to light yellow, then add 38g of 1,2-propanediol respectively, and continue stirring until the liquid in the reaction flask is dispersed into a uniform Emulsion, then add 10g palladium / carbon catalyst in the reaction bottle, add 60g water at last in the reaction bottle, the catalyzer that sticks to the bottle wall is washed clean. The reaction temperature was raised to 115° C., heated to reflux, and the reaction was stopped after 18 hours.

[0019] After the reaction was cooled to room temperature, it was centrifuged with a centrifuge, extracted 3 times with toluene, and washed 2 times with wate...

Embodiment 2

[0020] Embodiment 2: prepare 1 1000mL reaction bottle, add 90g water first under the protection of nitrogen, then slowly add 80g (2mol) sodium hydroxide in this reaction bottle, make sodium hydroxide dissolve completely under stirring state. Add 112g of 2-chloropyridine to the reaction flask, stir for 5 minutes, then the color of the liquid in the reaction flask changes from colorless to light yellow, then add 70g of ethylene glycol, and continue stirring until the liquid in the reaction flask is dispersed into a uniform emulsion , then add 20g palladium / carbon catalyst in reaction flask, add 110g water at last in reaction flask, the catalyzer that sticks to bottle wall is rinsed clean. The reaction temperature was raised to 115° C., heated to reflux, and the reaction was stopped after 18 hours.

[0021] After the reaction was cooled to room temperature, it was centrifuged with a centrifuge, extracted 3 times with toluene, and washed 2 times with water. The following clarifie...

Embodiment 3

[0022] Example 3: Prepare a 2500mL reaction flask, add 90g of water under nitrogen protection, then slowly add 110g of sodium hydroxide to the reaction flask, and completely dissolve the sodium hydroxide under stirring. Add 112g of 2-chloropyridine to the reaction bottle, stir for 5 minutes, and then the color of the liquid in the reaction bottle changes from colorless to light yellow, then add 72g of PEG-600 respectively, and continue stirring until the liquid in the reaction bottle is dispersed into a uniform milky liquid, then add 20g palladium / carbon catalyst in the reaction flask, add 110g water in the reaction flask at last, the catalyzer that sticks to the bottle wall is washed clean. The reaction temperature was raised to 115° C., heated to reflux, and the reaction was stopped after 18 hours.

[0023] After the reaction was cooled to room temperature, it was centrifuged with a centrifuge, extracted 3 times with toluene, and washed 2 times with water. The following cla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com