Hot press unit of silk winding and strip forming production device

A production device and winding technology, which is used in fluid pressure actuating devices, winding mechanisms, textiles and papermaking, etc., can solve problems such as unreasonable hot pressing units, achieve compact structure, improve hot pressing effect, and simple oil circuit Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

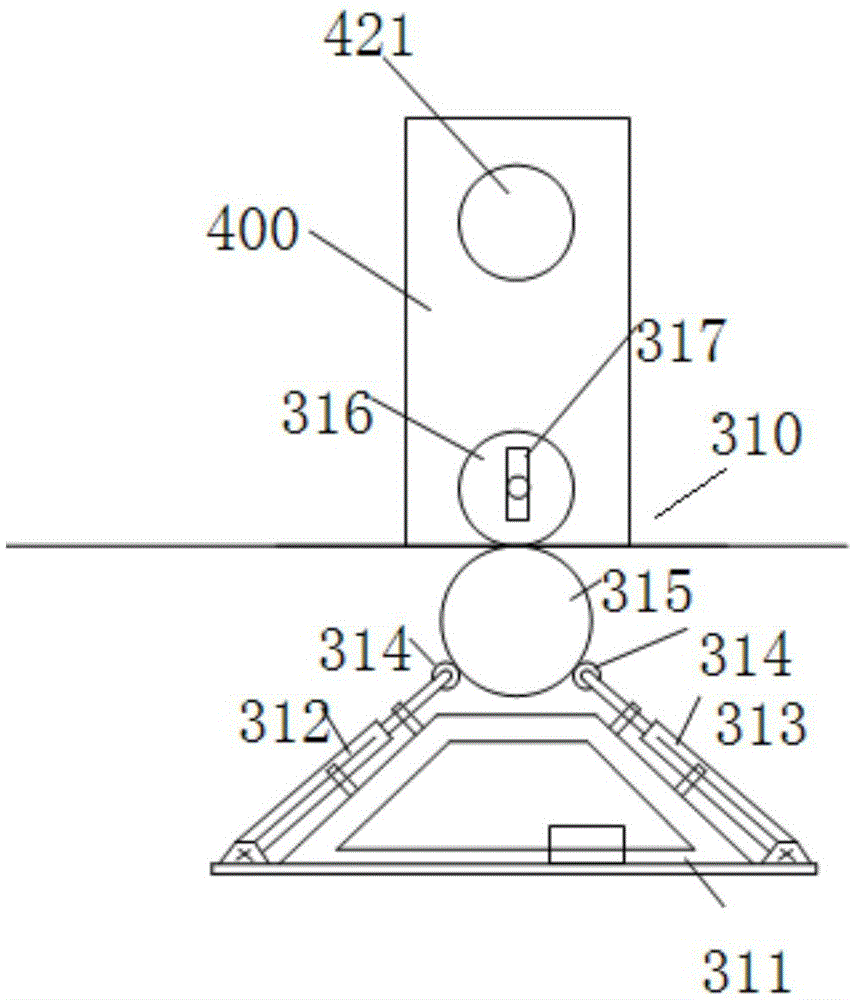

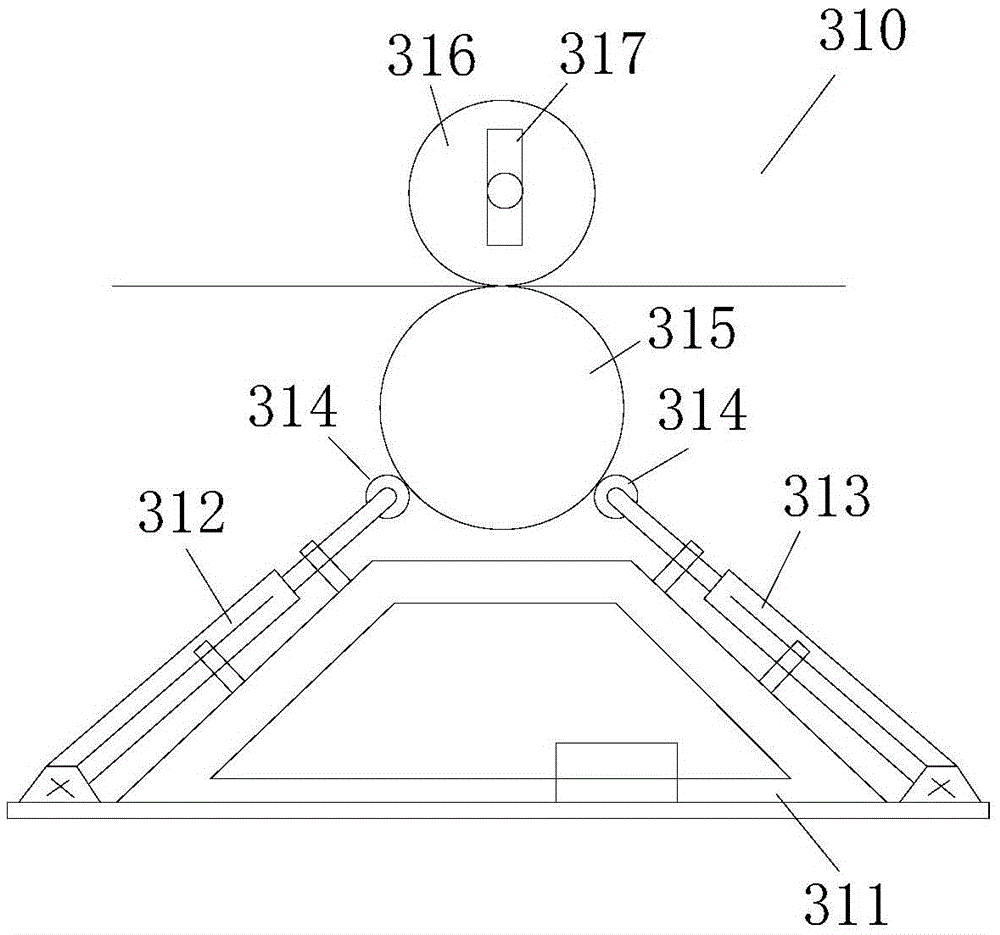

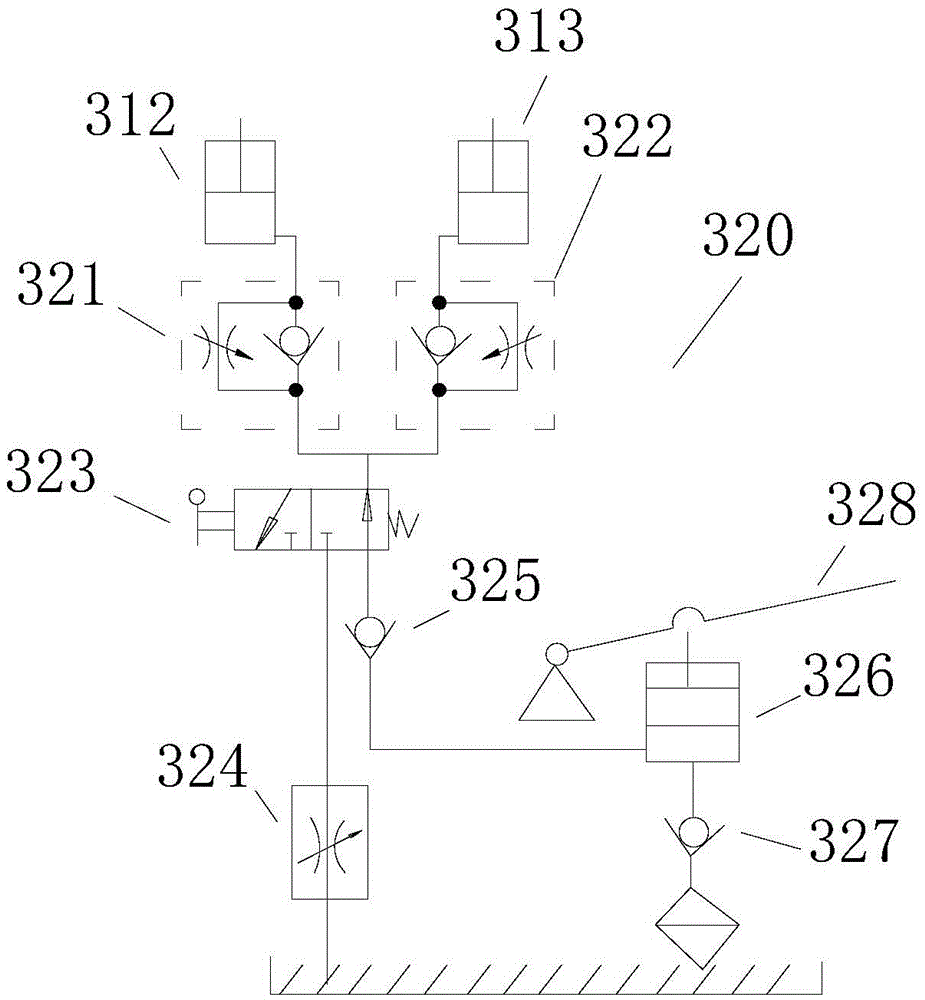

[0016] Embodiment: the hot-pressing unit of silk coiling production device, as attached Figure 1-Figure 3 As shown, it includes a thermal press mechanical part 310 and a thermal press hydraulic part 320. The thermal press mechanical part 310 includes a trapezoidal base 311. The two sides of the base 311 are provided with a first lifting cylinder 312 and a second lifting cylinder 313. The first lifting cylinder 312 And the extending end of the second lifting cylinder 313 is provided with a roller 314, the top of the roller 314 is provided with a pinch roller 315, the top of the pinch roller 315 is provided with a hot pressing roller 316, and the two shaft ends of the pinch roller 315 are provided with a moving device 317 The thermal pressure hydraulic part 320 includes a first one-way throttle valve 321 connected with the first lift cylinder 312 and a second one-way throttle valve 322 connected with the second lift cylinder 313, the first one-way throttle valve The valve 321 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com