Prestress strengthening method for external cables of bridges and culverts of prefabricated frames in gradient change jacking process

A prestressed, frame bridge technology, applied in the direction of buildings and road bottoms, etc., can solve problems such as slideway damage, loss of stability of force transmission rods, and prefabricated frame damage, and achieve the effect of reducing the workload of excavation and demolition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0071] The present invention will be further described below in conjunction with accompanying drawing.

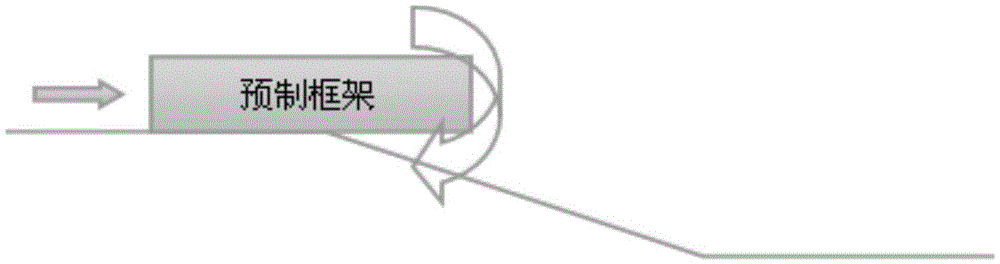

[0072] see Figure 17 , adopting the jacking construction method of reversed prefabricated frame with oil roof on the variable slope, setting a weak transition section at the point of slope change, that is, breaking the concrete slideway to form a weak section of soil foundation; placing the oil roof reversely at one end of the prefabricated frame, The back seat of the oil top is placed against the prefabricated frame, the piston rod of the oil top is connected with the force transmission rod and placed on the back, and the top force is exerted on the back through the oil top, and the prefabricated frame is pushed forward by the oil top back seat Mobile jacking; prefabricated frame jacking→removal of dowel members→follow-up pouring of stepped concrete backseat→installation of dowel members→prefabricated frame jacking→removal of dowel members→follow-up pouring of stepped con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com