Method for preventing large-section rectangular pipe-jacking tunnel from generating soil loading phenomenon

A technology of rectangular pipe jacking and large cross-section, applied in tunnels, earth-moving drilling, mining equipment, etc., can solve problems such as the inability to eliminate back soil phenomenon, and achieve the effect of avoiding back soil phenomenon, uplift or subsidence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following is an optional embodiment of the present invention, which can be modified and polished by those skilled in the art without changing the spirit and content of the present invention. The present invention will be further described below in conjunction with accompanying drawing:

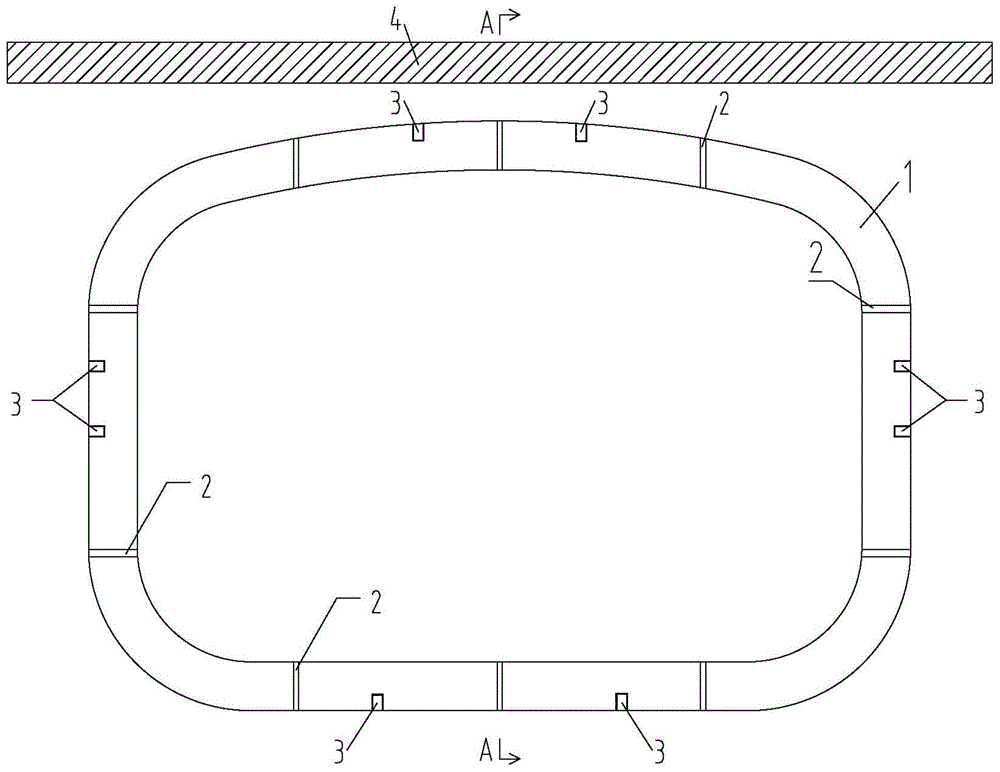

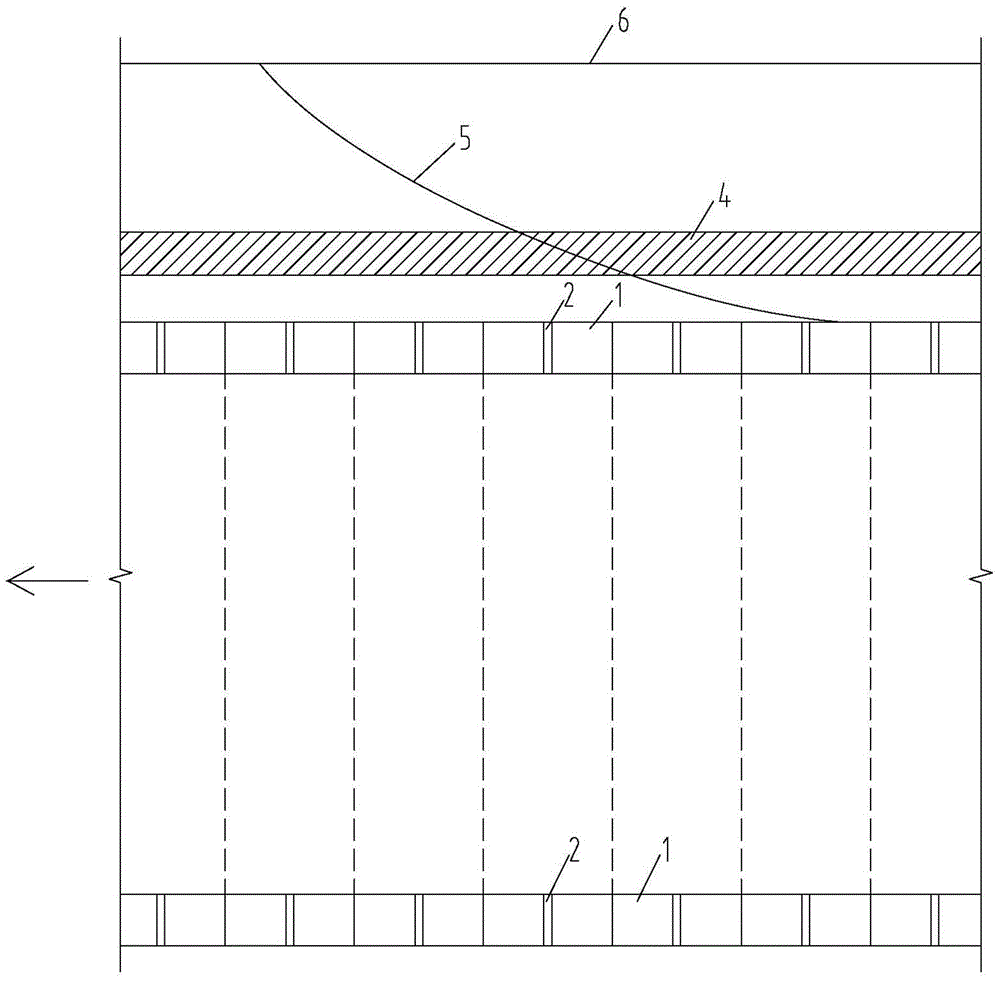

[0023] A method for preventing a large-section rectangular pipe-jacking tunnel from producing back-soil phenomenon, comprising the following steps in sequence:

[0024] The first step is to implement the working well of the pipe jacking tunnel;

[0025] The second step is to theoretically locate the profile of the pipe-jacking tunnel on the side wall of the working shaft adjacent to the tunnel;

[0026] The third step is to apply an isolation layer above the outline of the pipe jacking tunnel;

[0027] The fourth step is to make the tunnel door;

[0028] The fifth step is to hoist the pipe joint in place;

[0029] The sixth step is jacking construction.

[0030] Before the jack...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com