Precise and efficient adjustment process system for steam seal clearance of steam turbine

A technology of steam seal clearance and process system, which is applied in the field of radial clearance adjustment of the shaft system in the overhaul of the steam turbine generator set, and the precision adjustment of the steam seal clearance of the steam turbine body, can solve the problem of not further squeezing the steam seal clearance adjustment. , affecting the progress of the main line of the unit, ignoring the economics of the unit, etc., to achieve the effect of improving the overall economic performance, high practicality and economy, and shortening the maintenance cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

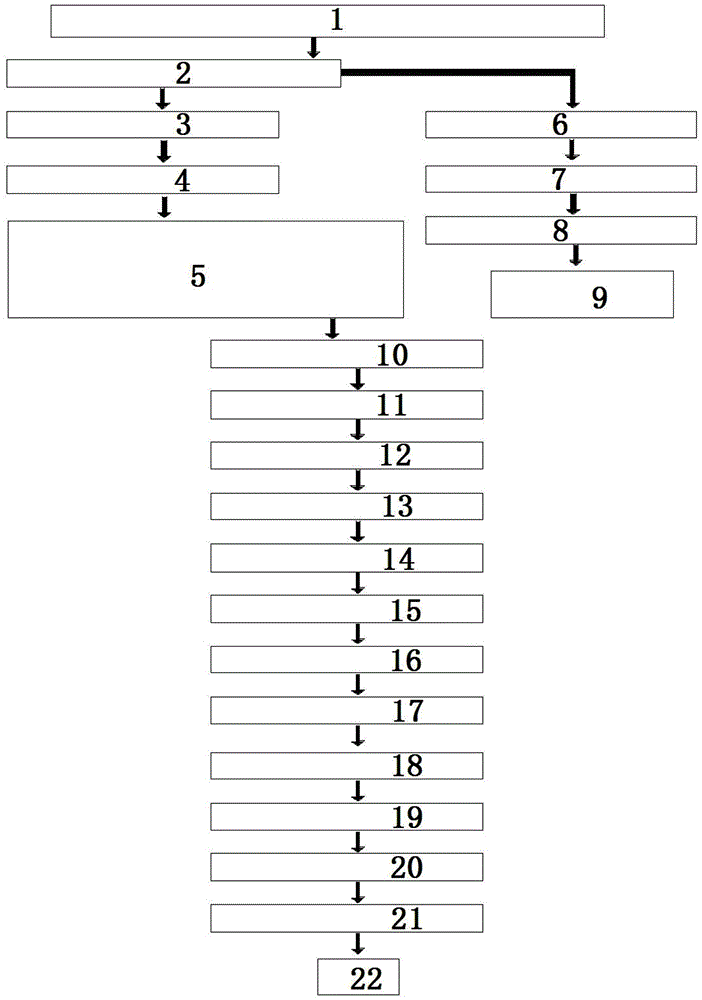

Method used

Image

Examples

Embodiment 1

[0072] The construction preparation before the precise adjustment of the steam seal gap of the present invention includes: construction personnel organization, site isolation, measuring tool calibration, tool preparation, spare parts preparation, technical data preparation and safety protection equipment preparation, etc. At the same time, the following procedures must be completed in advance: the static part of the steam turbine should be cleaned and inspected to ensure that there is no jamming phenomenon, the center of the shafting system has been initially adjusted, the tightness of the cylinder has been checked to pass the test, the deformation of the cylinder, diaphragm, rotor, and sag corrections have been completed, and the correction values for each position have been completed. Good records, all levels of partitions, balance pistons, and the adjustment of the center of the dimple of the steam seal body have been completed.

[0073] The replacement and processing of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com