A device for realizing continuous power supply of instruments and meters on the rotating equipment operation site

A technology for rotating equipment and job sites. It is applied to electromechanical devices, wind turbines, and mechanical equipment in the same direction as the wind. It can solve problems such as production loss, high cost, and complicated wiring. It can save energy and be easy to use and operate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

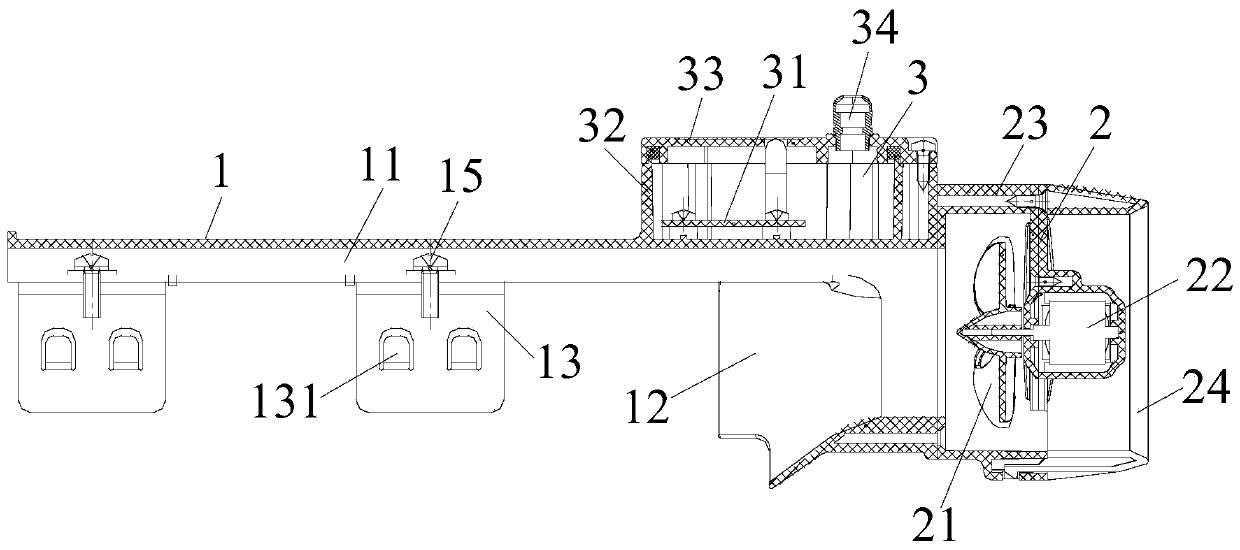

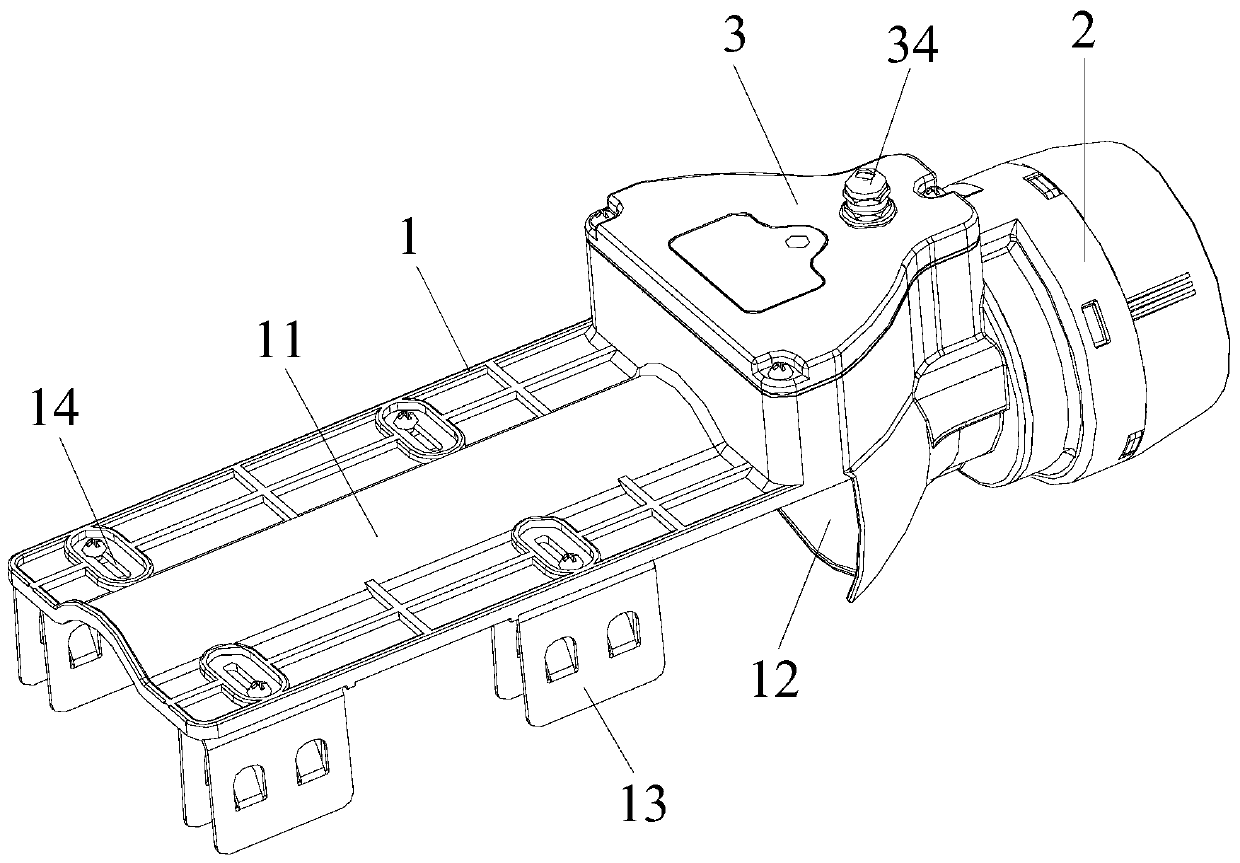

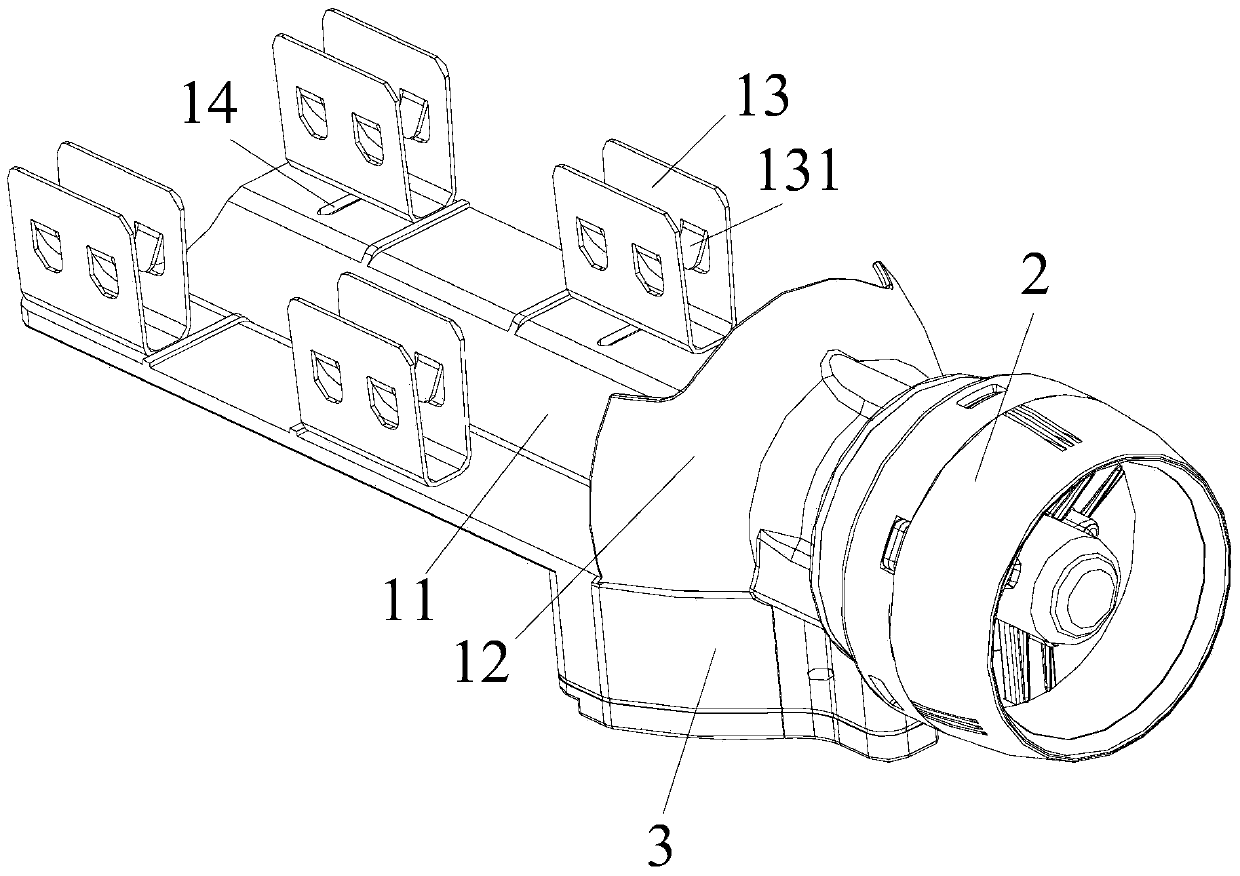

[0025] combine Figure 1 to Figure 3 As shown: a device provided in this embodiment to realize continuous power supply of instruments and meters at the working site of rotating equipment, including a wind collecting hood 1, a wind power generation unit 2 and an output power supply unit 3, the wind collecting hood 1 is set on the drive rotating equipment On the wind channel of the air-cooled motor (not shown in the figure), the wind power generation unit 2 is arranged at the tail of the wind collecting hood 1, the wind power generation unit 2 is electrically connected to the output power supply unit 3, and the output power supply The unit 3 is respectively electrically connected to the instruments and meters (not shown in the figure) at the rotating equipment operation site.

[0026] In this example:

[0027] The wind collecting hood 1 includes an air guide part 11 and an air intake port 12, the air guide part 11 is arranged on the air flow channel formed by the cooling ribs o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com