Embedded sliding bearing lubricating film pressure wireless sensing and monitoring device

A sliding bearing and wireless sensing technology, which is applied in circuit devices, the measurement of properties of piezoelectric resistance materials, emergency power supply arrangements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below with reference to the accompanying drawings and specific embodiments.

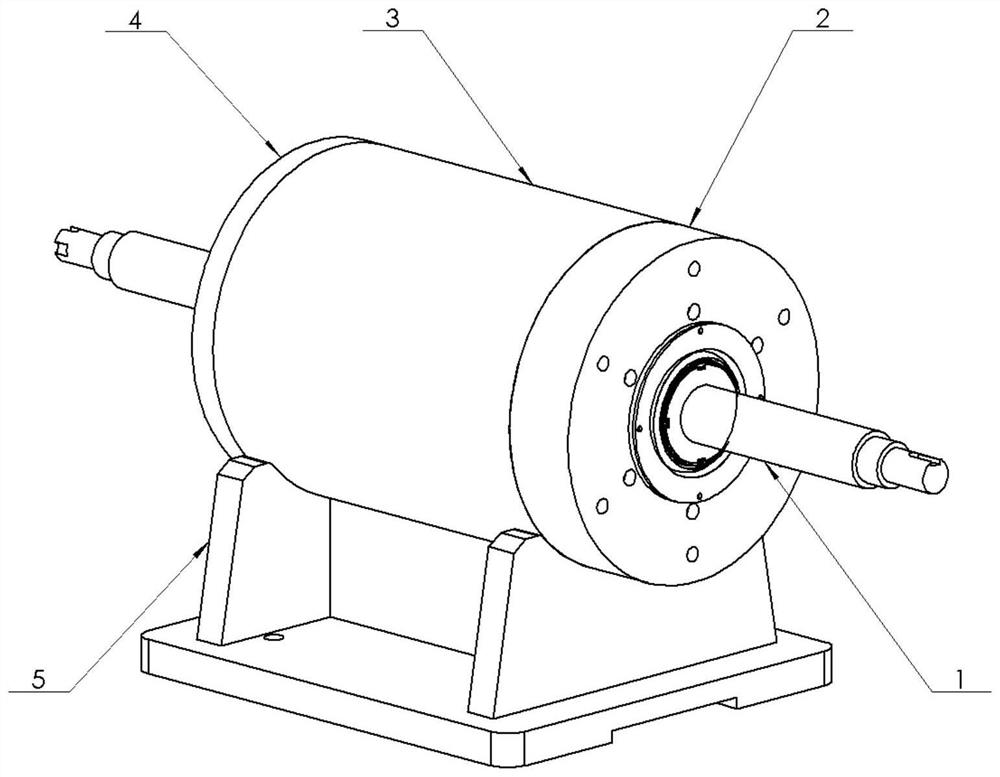

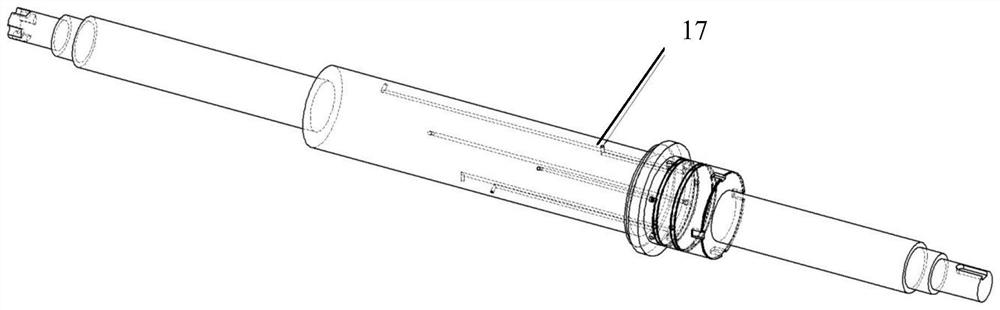

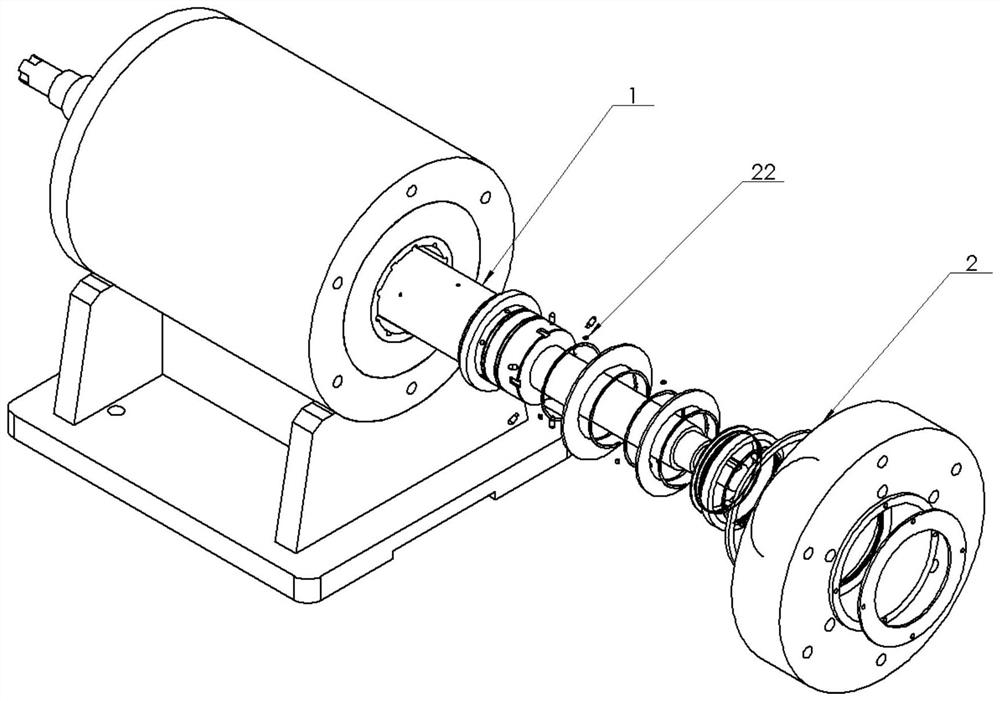

[0032] like figure 1 As shown, the sliding bearing includes a bearing seat 5, a rotating machine shaft 1, an alloy bearing housing 3, and a left end cover 4 and a right end cover 2 located at both ends of the bearing. The rotating machine shaft 1 is sleeved with a bearing copper sleeve 6, the bearing copper The inner surface of the sleeve 6 is covered with a rubber bearing bush 7, and the inner surface of the rubber bearing bush 7 is provided with a groove, the bearing copper sleeve 6 is tightly fitted and fixed with the bearing shell 3, the outer end surface of the right end cover 2 is provided with an end cover plastic shell 10, and the right end cover 2 A sealing ring A14 and a sealing ring B15 are arranged between the shaft 1 and the rotating machinery. The sealing ring A14 and the sealing ring B15 cooperate with each other to realize the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sensitivity | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com