Heat returning closed cooling recirculation system of Brighton scramjet

A circulating system and scramjet technology, applied in ramjet engines, machines/engines, rocket engine devices, etc., can solve the problems of difficult cooling of scramjet engines, difficulty in taking air from the fuel supply system, and large fuel flow, etc. Achieve the effect of improving energy utilization, good component matching performance, and good heat absorption performance

Inactive Publication Date: 2011-01-05

HARBIN INST OF TECH

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The purpose of the present invention is to solve the existing hypersonic vehicle scramjet cooling difficulties, large cooling fuel flow and insufficient heat sink and fuel supply system gas intake difficulties, and proposes a scramjet heat recovery Closed Brayton cooling cycle system

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

specific Embodiment approach 1

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

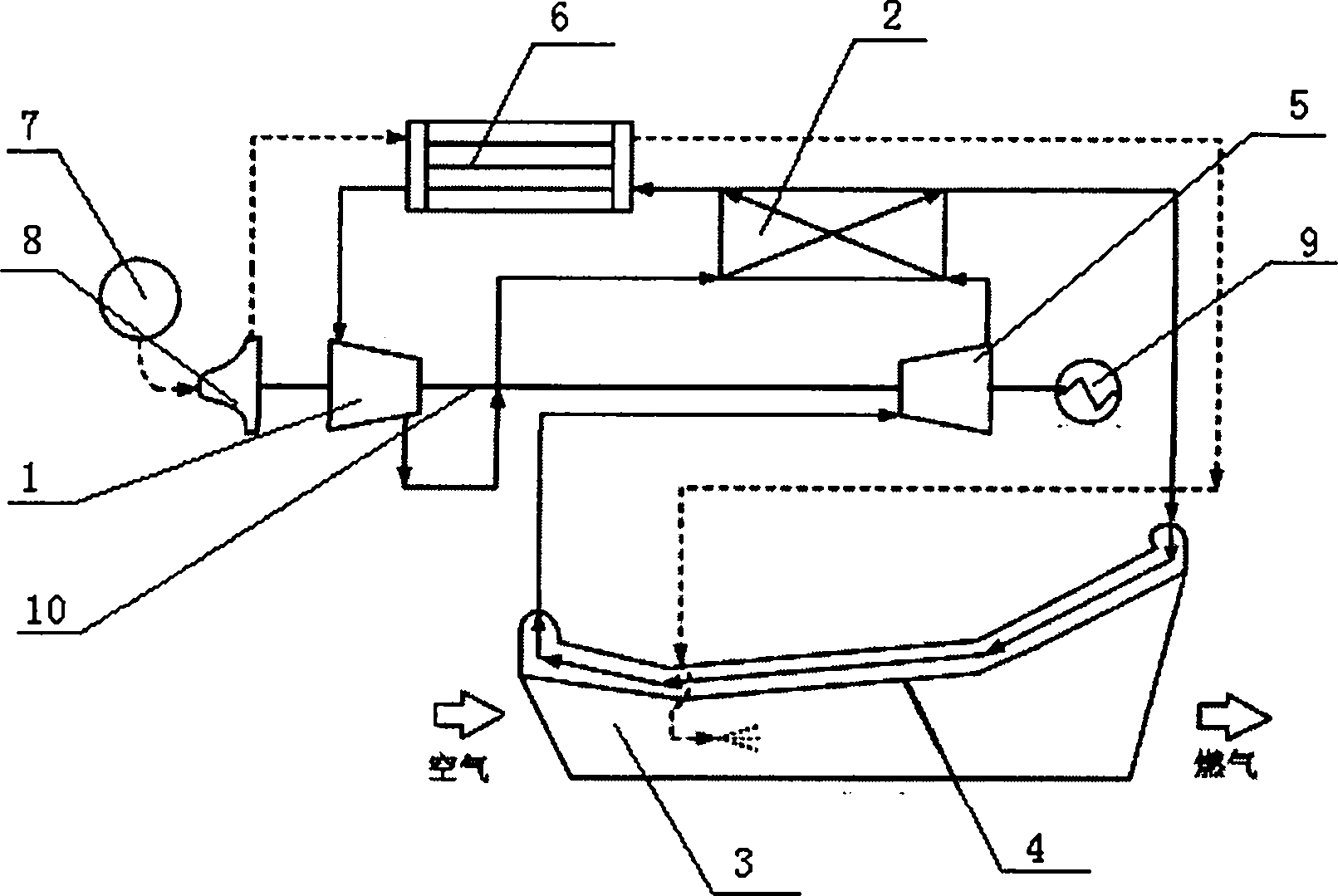

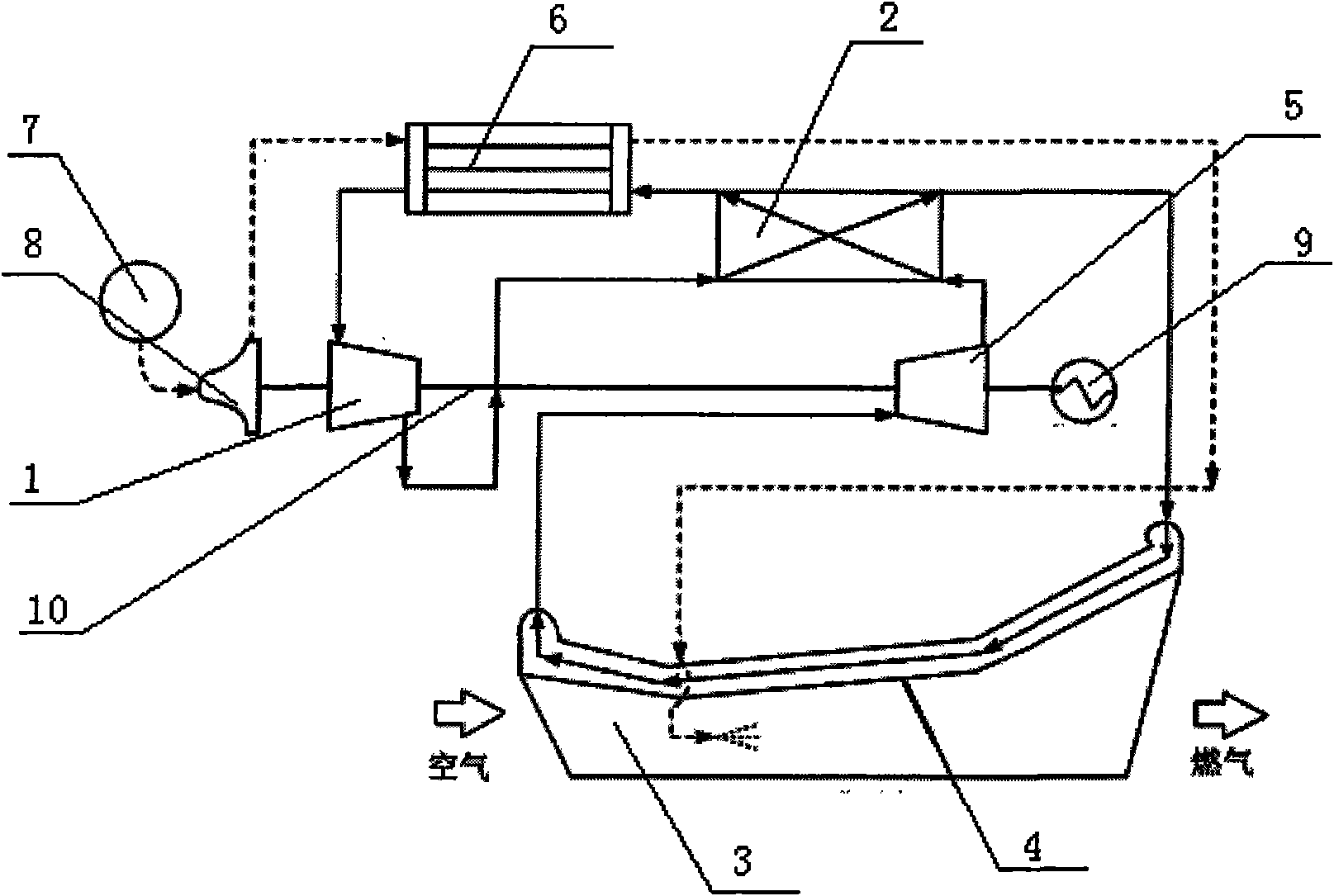

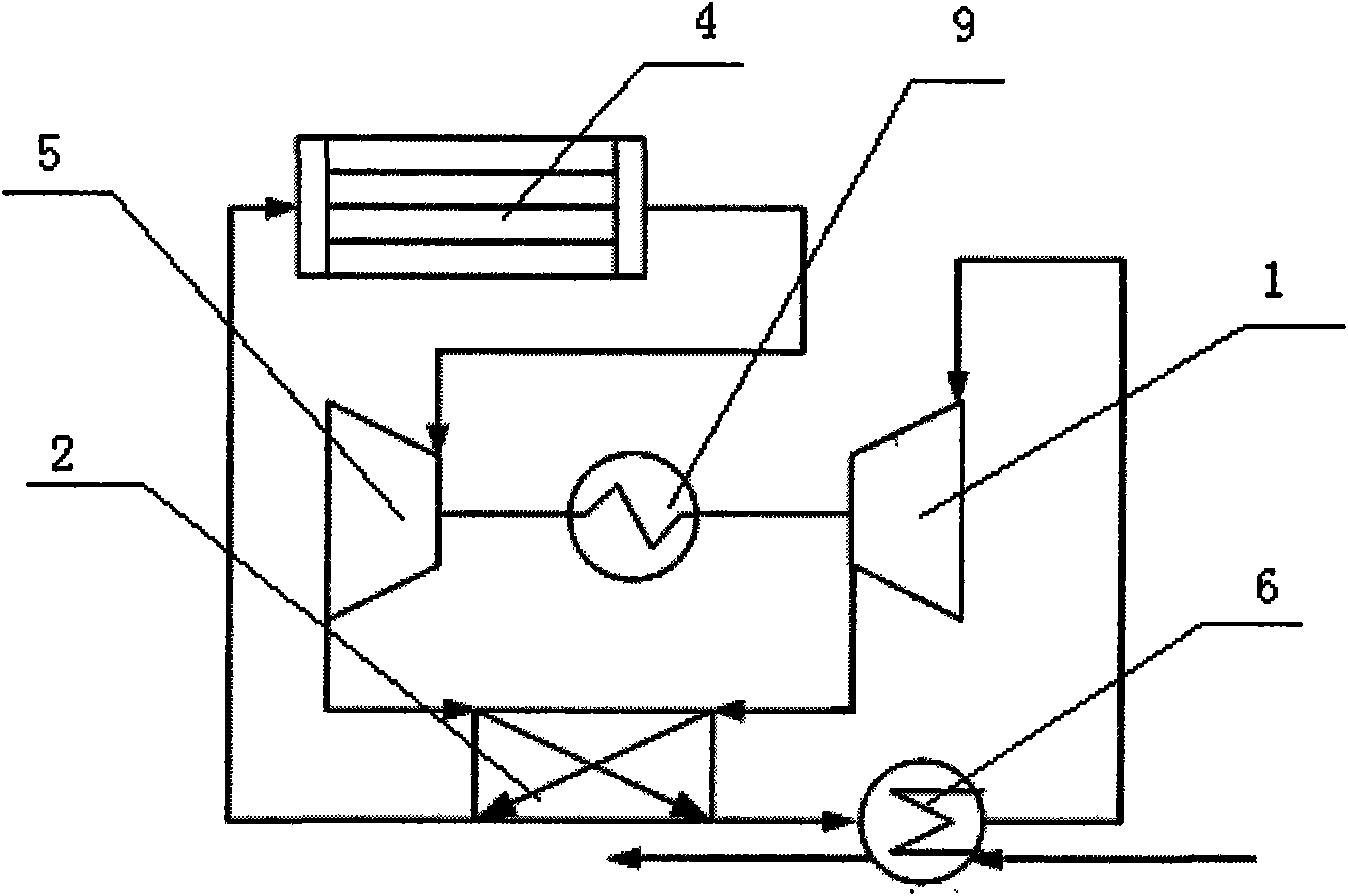

The invention discloses a heating returning closed cooling recirculation system of a Brighton scramjet, which relates to a cooling recirculation system of a scramjet. The invention aims at solving theproblems of cooling difficulty, a large amount of cooling fuel flow, insufficient heat sink and gas-fetching difficulty of the fuel supply system of the scramjet of a prior hypersonic aerial vehicle.One end of a central axis is connected with a generator and another end thereof is respectively connected with a gas compressor and a fuel pump. A turbine is arranged on the central axis between thegenerator and the gas compressor. A cooling channel is arranged on the external wall at the upper part of the scramjet. The cooling recirculation system is provided with a primary cooling loop and a secondary cooling loop. The cooling recirculation system of the scramjet is applicable to the thermal protection of the hypersonic aerial vehicle and the cooling of the scramjet.

Description

Scramjet Regenerative Closed Brayton Cooling Cycle System technical field The invention relates to a cooling cycle system of a scramjet engine. Background technique Hypersonic vehicles with a flying Mach number greater than 5 are a hot topic in current research, including the development of single-stage or two-stage orbital space planes, space-to-ground transport vehicles, and hypersonic cruise missiles. One of the key technologies of the air-breathing hypersonic vehicle with the scramjet engine as the propulsion system is the thermal protection of the vehicle, in which the cooling of the engine is the most difficult part, because even if composite materials are used, it is difficult to withstand the huge heat generated inside the engine. heat load. It is generally believed that fuel is the best coolant, but theoretical analysis and practice show that the coolant flow rate will be greater than the propulsion fuel flow rate after reaching a certain flight Mach number, so e...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): F02K7/10F02K9/64

Inventor 鲍文秦江于达仁周伟星

Owner HARBIN INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com