Anti-scouring control valve

A control valve and anti-scouring technology, which is applied in the direction of valve details, valve devices, and devices for absorbing fluid energy of the valve, can solve the problems of valve core and seat erosion, short service life, easy blockage of valve core and valve seat, etc. To achieve the effect of solving the erosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

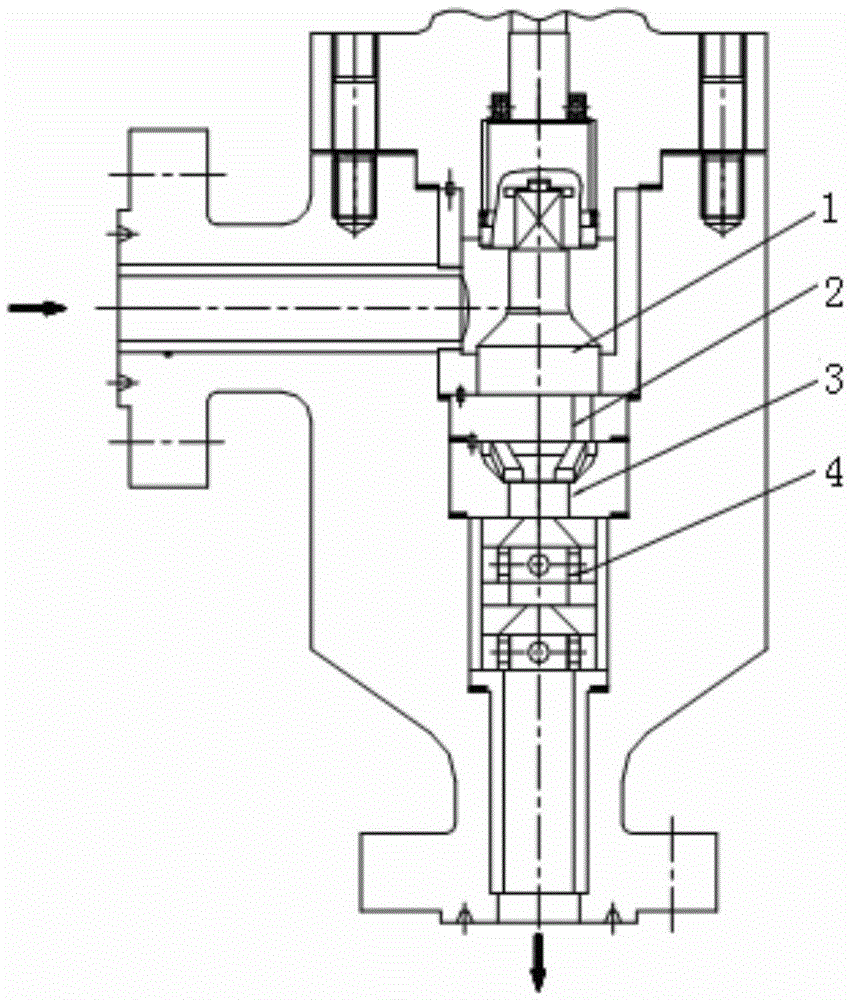

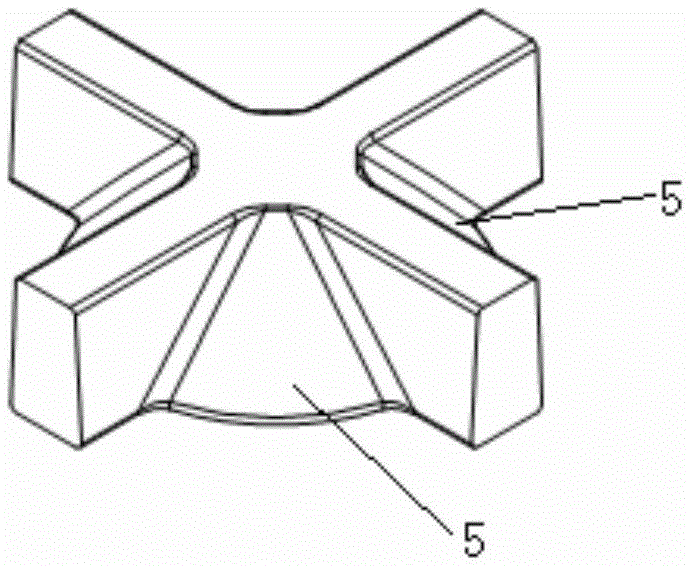

[0022] like figure 1 , 2 , 3, the present invention provides a new type of control valve for oil-coal slurry pumps, including a valve core 1 and a valve seat 2, a guide seat 3 is installed in the medium flow channel at the bottom of the valve seat 2, and a flow guide seat 3 is installed in the medium flow channel at the bottom of the valve seat 2, and the Two throttling pieces 4 are installed at the bottom of the flow guiding seat 3 . Among them, the guide seat 3 includes a cross bracket, and guide vanes 5 are provided at the four right-angle joints on the cross bracket, and the surface of the guide vanes 5 that is in contact with the medium is a conical surface, and the throttling member 4 and the valve The seats 2 are pressed and fixed in the valve body through the guide seat 3 .

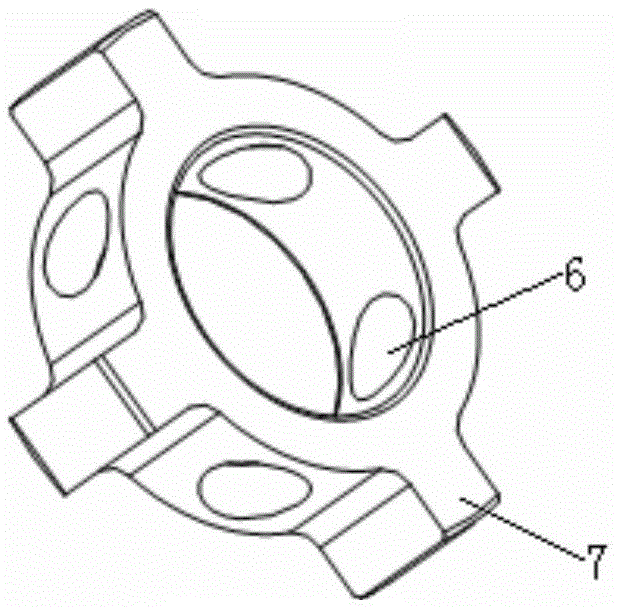

[0023] Wherein the throttling member 4 comprises a circular ring, four through holes 6 (symmetrical and uniform distribution) are arranged on the inner wall of the circular ring, and four bosses...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com