Gas water heater and its composite heat exchanger

A gas-fired water heater and heat exchanger technology, which is applied to heat exchange equipment, water heaters, fluid heaters, etc., can solve problems such as the inability to effectively improve the thermal efficiency of the water heater and the limited effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

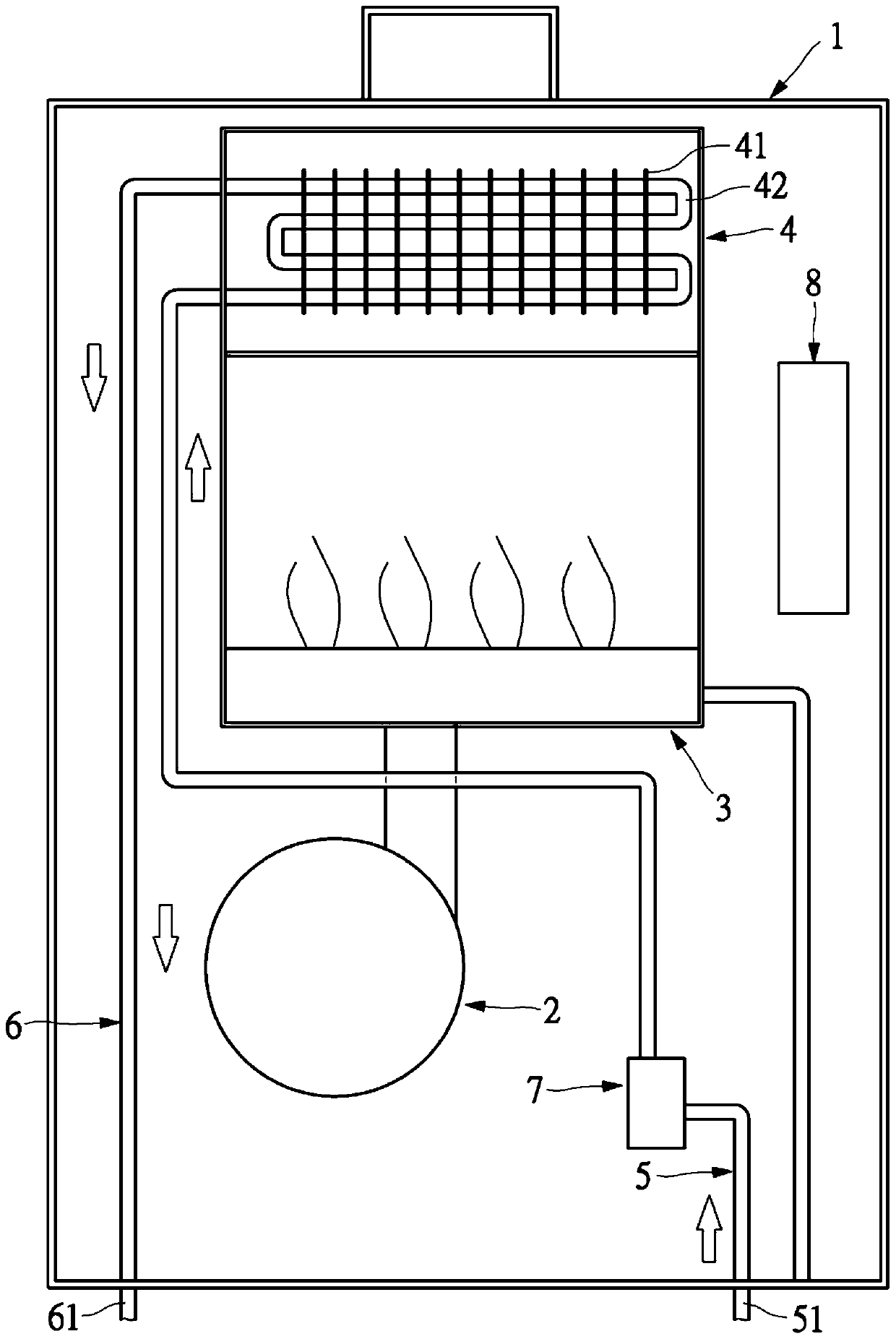

[0080] see figure 1 , The present invention provides a gas water heater, which includes a body 1, a fan 2, a burner (fire row) 3 and a heat exchanger 4. The body 1 is a hollow shell, and the fan 2, the burner 3 and the heat exchanger 4 are arranged inside the body 1. The positions of the fan 2, the burner 3 and the heat exchanger 4 are not limited, and can be adjusted according to needs. Variety. In this embodiment, the fan 2 , the burner 3 and the heat exchanger 4 are sequentially arranged inside the body 1 from bottom to top, and the burner 3 is located between the fan 2 and the heat exchanger 4 . When the burner 3 is ignited, the burner 3 can generate high-temperature combustion gas, which is pushed upwards, and the combustion gas contacts the heat exchanger 4 to perform heat exchange, so that the water flowing through the heat exchanger 4 can It is heated from normal temperature to high temperature, and then discharges hot water for use.

[0081] The heat exchanger 4 is...

no. 2 example

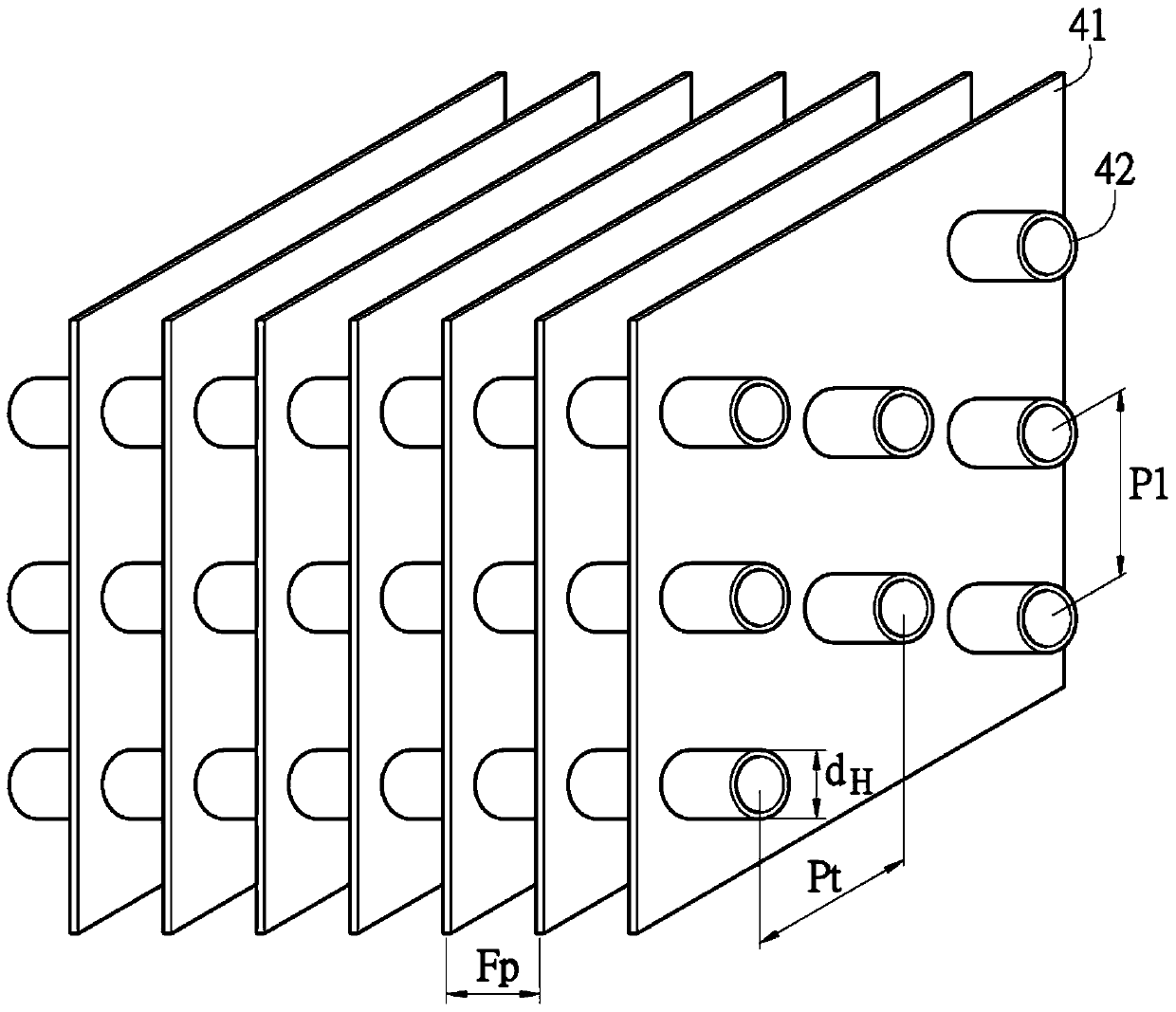

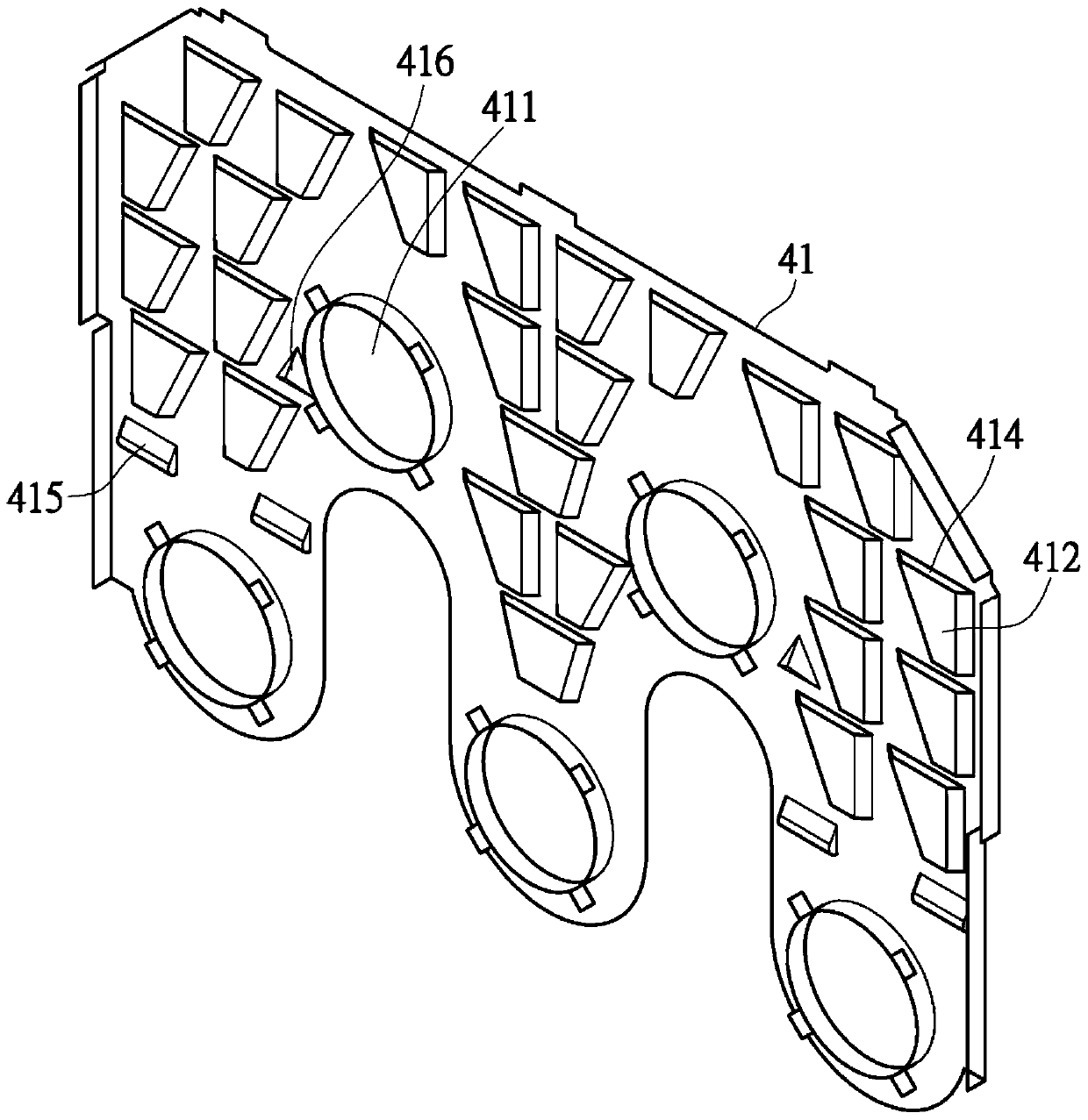

[0105] see Figure 2 to Figure 4 , Figure 8 to Figure 10 , the present embodiment discloses a pyramidal vortex generator 416 . The vortex generators 416 are punched and formed on the fins 41 respectively, and the vortex generators 416 can respectively protrude from one side or the other side of the fins 41 . Each vortex generator 416 is a pyramid, and the vortex generator 416 has a triangular bottom C and a plurality of slopes D, and the vortex generator 416 is connected to the fin 41 with the bottom C, and is defined as follows:

[0106] The distance between two adjacent fins is Fp, the width of the vortex generator is g1, the length of the vortex generator is gt, the height of the vortex generator is gh, and the vertical distance between the lower edge of the vortex generator and the center point of the water pipe at the top is Ph, the water pipe The horizontal pitch is Pt, and the longitudinal pitch of the water pipe is Pl.

[0107] If the following relational condition...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com